High Voltage Cables

High Voltage Cables can be divided into aluminum-core high-voltage cables and copper-core cables according to different materials. Voltage Level Range: 6/64 ኪ.ቪ, 48/66 ኪ.ቪ, 66/120 ኪ.ቪ, 127/220 kV and other ultra-high voltage. Due to the complex environmental conditions and special requirements in certain areas, the use of copper core cables is more reliable in terms of quality and safety. According to our production experience, the selection of technical specifications and cross-sectional area of high-voltage cables should be made with reference to the surrounding environment, the corresponding laying method and the performance of electrical equipment. Welcome to get a free quotation.

Types of VERI High Voltage Cable

YJV22 10kv 35kv High Coltage Copper Cable

YJV22 high voltage cables are used for power transmission and distribution high tension cable systems with rated voltages of 0.6/1kv, 1.8/3kv, 3.6/6kv, 6/10kv, 8.7/10kv, 8.7/15kv, 12/20kv, 21/35kv, 26/35kv.

1. XLPE insulated, PVC sheathed power cables (YJV, YJLV) are suitable for indoors, tunnels, pipes, and buried in soil (not subject to mechanical force)

2. XLPE insulated, steel tape armored PVC sheathed power cables (YJV22, YJLV22) are suitable for indoor, tunnel, pipe penetration, and buried in soil

3. XLPE insulated, steel wire armored PVC sheathed power cables (YJV32, 42, YJLV32, 42) are suitable for shafts, water, places with drop, and can withstand external forces.

The Minimum Bend Radius of the Cable

ንጥል | Three -core | |

Unarmored | Armored | |

Minimum bend radius of the cable in course of installation. | 15D | 12D |

The minimum bend radius of the cable close to the junction box and terminal | 12D | 10D |

Note: D is outer diameter of the cable | ||

HV Cable Size Specification

Cross section area(ሚሜ²) | Insulated thickness(ሚ.ሜ) | Metal shield thickness(ሚ.ሜ) | Jacket thickness(ሚ.ሜ) | OD(ሚ.ሜ) | Weight(ኪ.ግ) |

3×25 | 4.5 | 30×0.10 | 2.4 | 44.8 | 2251.6 |

3×35 | 4.5 | 40×0.10 | 2.5 | 47.2 | 2655.9 |

3×50 | 4.5 | 40×0.10 | 2.6 | 50.4 | 3217.3 |

3×70 | 4.5 | 40×0.10 | 2.7 | 54.0 | 3957.2 |

3×95 | 4.5 | 40×0.10 | 2.8 | 57.7 | 4884.7 |

3×120 | 4.5 | 40×0.10 | 2.9 | 60.9 | 5754.2 |

3×150 | 4.5 | 40×0.10 | 3.0 | 64.5 | 6788.0 |

3×185 | 4.5 | 40×0.10 | 3.1 | 68.2 | 7961.6 |

3×240 | 4.5 | 40×0.10 | 3.3 | 73.5 | 9801.3 |

3×300 | 4.5 | 40×0.10 | 3.4 | 78.3 | 11725.3 |

3×400 | 4.5 | 40×0.10 | 3.7 | 85.8 | 14799.2 |

Product Structure Features:

1. Has Good High-Temperature Resistance: XLPE insulation uses chemical or physical methods to change the structure of polyethylene molecules into a three-dimensional network structure. The three-dimensional network structure has good heat resistance and can be used in Long-term work at a high temperature of 90 degrees Celsius, the lifespan can be as long as 40 years.

2. Good Insulation Performance: polyethylene not only retains the insulation performance of cross-linked polyethylene but also has a further improvement in insulation resistance.

3. High Mechanical Properties: hardness, stiffness, wear resistance, and impact resistance have been improved

4. Chemical Resistance: XLPE itself has strong acid and alkali resistance and oil resistance

5. Environmental Protection: Since the products of cross-linked polyethylene combustion are water and carbon dioxide, the environmental pollution is low, and it meets the fire safety requirements.

6. The maximum rated temperature of the cable conductor is 90°C, and the maximum temperature during the short circuit (the longest duration does not exceed 5S) does not exceed 250°C.

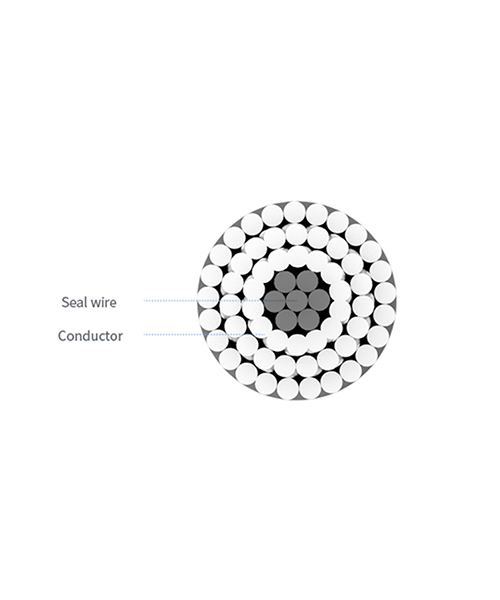

High Voltage Aluminum Overhead Lines

Aluminum conductor, steel reinforced overhead cable, is mainly used in power transmission lines with high voltage. Its advantages include high mechanical strength, good electrical conductivity, corrosion resistance, light unit volume, easy erection, high-temperature resistance, simple structure, convenient installation, good maintenance, and large transmission capacity. The High-voltage steel cable of Acsr consists of a solid or stranded steel core surrounded by strands of aluminum.

- መሪ: Aluminum

- Street lighting conductor: Round-stood or compacted Aluminum conductor

- የኢንሱሌሽን: LDPE/HDPE/XLPE/PVC

ስታንዳርድ: GB/T12527/IEC60502/NFC 33-209/BS 7870/ANSI/ICEA S-76-474 AS/NZS 35601

HV ACSR Conductor According to GOST 839-80

| Section | Aluminum part | Steel part | Min. Breaking Strength | |||

|---|---|---|---|---|---|---|

| Number of wires | Nom. wire diameter | Number of wires | Nom. wire diameter | |||

| 1 | 16/2.7 | 6 | 1.85 ሚ.ሜ. | 1 | 1.85 ሚ.ሜ. | 6,220 ኤን. |

| 2 | 25/4.2 | 6 | 2.30 ሚ.ሜ. | 1 | 2.30 ሚ.ሜ. | 9,296 ኤን. |

| 3 | 35/6.2 | 6 | 2.80 ሚ.ሜ. | 1 | 2.80 ሚ.ሜ. | 13,524 ኤን. |

| 4 | 50/8.0 | 6 | 3.20 ሚ.ሜ. | 1 | 3.20 ሚ.ሜ. | 17,112 ኤን. |

| 5 | 70/11 | 6 | 3.80 ሚ.ሜ. | 1 | 3.80 ሚ.ሜ. | 24,130 ኤን. |

| 6 | 70/72 | 18 | 2,20 ሚ.ሜ. | 19 | 2.20 ሚ.ሜ. | 96,862 ኤን. |

| 7 | 95/16 | 6 | 4.50 ሚ.ሜ. | 1 | 4.50 ሚ.ሜ. | 33,369 ኤን. |

| 8 | 120/19 | 26 | 2.40 ሚ.ሜ. | 7 | 1.85 ሚ.ሜ. | 41,521 ኤን. |

| 9 | 120/27 | 30 | 2.20 ሚ.ሜ. | 7 | 2.20 ሚ.ሜ. | 49,465 ኤን. |

| 10 | 150/19 | 24 | 2.80 ሚ.ሜ. | 7 | 1.85 ሚ.ሜ. | 46,307 ኤን. |

| 11 | 150/24 | 26 | 2.70 ሚ.ሜ. | 7 | 2.10 ሚ.ሜ. | 52,279 ኤን. |

| 12 | 150/34 | 30 | 2.50 ሚ.ሜ. | 7 | 2.50 ሚ.ሜ. | 62,643 ኤን. |

| 13 | 185/24 | 24 | 3.15 ሚ.ሜ. | 7 | 2.10 ሚ.ሜ. | 58,075 ኤን. |

| 14 | 185/29 | 26 | 2.98 ሚ.ሜ. | 7 | 2.30 ሚ.ሜ. | 62,055 ኤን. |

| 15 | 185/43 | 30 | 2.80 ሚ.ሜ. | 7 | 2.80 ሚ.ሜ. | 77,767 ኤን. |

| 16 | 205/27.0 | 24 | 3.30 ሚ.ሜ. | 7 | 2.20 ሚ.ሜ. | 63,740 ኤን. |

| 17 | 240/32 | 24 | 3.60 ሚ.ሜ. | 7 | 2.40 ሚ.ሜ. | 75,050 ኤን. |

| 18 | 240/39 | 26 | 3.40 ሚ.ሜ. | 7 | 2.65 ሚ.ሜ. | 80,895 ኤን. |

| 19 | 240/56 | 30 | 3.20 ሚ.ሜ. | 7 | 3.20 ሚ.ሜ. | 98,253 ኤን. |

| 20 | 300/39 | 24 | 4.00 ሚ.ሜ. | 7 | 2.65 ሚ.ሜ. | 90,574 ኤን. |

| 21 | 300/48 | 26 | 3.80 ሚ.ሜ. | 7 | 2.95 ሚ.ሜ. | 100,623 ኤን. |

| 22 | 300/204 | 54 | 2.65 ሚ.ሜ. | 37 | 2.65 ሚ.ሜ. | 284,579 ኤን. |

| 23 | 330/43.0 | 54 | 2.80 ሚ.ሜ. | 7 | 2.80 ሚ.ሜ. | 103,784 ኤን. |

| 24 | 400/18 | 42 | 3.40 ሚ.ሜ. | 7 | 1.85 ሚ.ሜ. | 85,600 ኤን. |

| 25 | 400/51 | 54 | 3.05 ሚ.ሜ. | 7 | 3.05 ሚ.ሜ. | 120,481 ኤን. |

| 26 | 400/64 | 26 | 4.34 ሚ.ሜ. | 7 | 3.40 ሚ.ሜ. | 129,183 ኤን. |

| 27 | 400/93 | 30 | 4.15 ሚ.ሜ. | 19 | 2.50 ሚ.ሜ. | 173,715 ኤን. |

| 28 | 500/27 | 76 | 2.84 ሚ.ሜ. | 7 | 2.20 ሚ.ሜ. | 112,188 ኤን. |

| 29 | 500/64 | 54 | 3.40 ሚ.ሜ. | 7 | 3.40 ሚ.ሜ. | 148,257 ኤን. |

| 30 | 600/72 | 54 | 3.70 ሚ.ሜ. | 19 | 2.20 ሚ.ሜ. | 183,835 ኤን. |

APPLICATION

The type of these cables uses in electricity distribution lines laying across rivers and valleys where special geographical creatures exist. The conductor of ACSR represents the most important component of an overhead power line because they have to ensure economical and reliable transmission and contribute considerably to the total line costs.

HDPE HV Cable 35KV to 110KV

HDPE high voltage cables are typically used in high voltage power transmission and distribution systems and are suitable for installation in ducts, trenches or direct burial underground or in buildings. These cables are also well suited for connecting wind farms and other renewable energy sources to existing grid systems.

መሪ: Multi-strand round or segmented compacted copper or aluminum

Insulation shield: Non-metallic – semiconductor layer

Tape: Semi-conductive resistive water tape

ሽፋን: Lead

ሽፋን: HDPE sheath (custom LSZH available)

ስታንዳርድ: IEC 60840

HDPE HV Technical Specification

መጠን | Conductor Diameter | Conductor Screen Thickness | የኢንሱሌሽን Thickness | Nominal Core Diameter | Copper Wire Shield Area | HDPE Sheath Thickness | Approximate Overall Diameter |

ሚሜ² | ሚ.ሜ | ሚ.ሜ | ሚ.ሜ | ሚ.ሜ | ሚሜ² | ሚ.ሜ | ሚ.ሜ |

150 | 14.4 | 1.2 | 18 | 56.2 | 95 | 4 | 70.6 |

185 | 15.6 | 1.2 | 18 | 57.4 | 95 | 4 | 71.8 |

240 | 18.3 | 1.2 | 18 | 60.1 | 95 | 4 | 74.5 |

300 | 20.6 | 1.2 | 18 | 62.4 | 95 | 4 | 76.8 |

400 | 22.9 | 1.2 | 18 | 64.7 | 95 | 4 | 79.1 |

500 | 26.4 | 1.2 | 18 | 68.2 | 95 | 4.5 | 83.6 |

630 | 29.8 | 1.2 | 18 | 71.6 | 95 | 4.5 | 87 |

800 | 36 | 1.2 | 18 | 77.8 | 95 | 4.5 | 93.2 |

1000 | 38.2 | 1.5 | 18 | 81.2 | 95 | 4.5 | 97.6 |

1200 | 42.8 | 1.5 | 18 | 85.8 | 95 | 4.5 | 102.2 |

1400 | 46.4 | 1.5 | 18 | 89.4 | 95 | 4.5 | 105.8 |

1600 | 48.9 | 1.5 | 18 | 91.9 | 95 | 4.5 | 108.3 |

Product Advantages:

VERI Cables can ensure that the HDPE high voltage cables we produce meet national or international technical specifications. We can also provide accurate cable laying solutions for high voltage power projects based on the experience of our technical team, and all products can be supplied with formal test certificates.

FAQ

What is the maximum voltage cable that can be supplied?

What is the minimum order quantity?

How do I communicate with you?

Laying of VERI High Voltage Cables

Inspection before cable laying: whether the model and specifications meet the requirements, the insulation should be good, the appearance should be complete, and there should be no traces of trauma.

A spare length should be reserved near the cable terminal, and a spare length should be reserved for the directly buried cable in the wave-shaped laying. The distance between each fulcrum of the cable shall be as specified in the design. When there are no design regulations, it should not be greater than rubber ኬብሎች. These plastic cables are horizontal 1M, vertical 2M, and cables suspended on steel cables that are horizontal 0.75M. The bending radius of the cable should not be less than 10 times the outer diameter of the cable (armored or unarmored multicore plastic insulated power cable).

When laying the cables, the cables should be drawn out from the upper end of the reel, and avoid friction and drag of the wires on the bracket and the ground. The cables should not be crossed when laying, they should be neatly arranged, and fixed, and signs should be installed. There should be firm stakes at the corners of the directly buried cables. When cables enter cable trenches, tunnels, buildings, and pipes, the entrances and exits should be closed. Clamps and fixtures for AC single-core cables should not have a closed magnetic circuit composed of iron.

Transportation with Professional Service

VERI Cable has multiple ways to protect your cables, ከጠንካራ እና ሙያዊ ማጓጓዣ ማሸጊያ እና አጠቃላይ ኢንሹራንስ ጋር. ከማጓጓዙ በፊት, የእኛ ኬብሎች በእንጨት ዊልስ እና በቆርቆሮ ሳጥኖች ውስጥ የታሸጉ ናቸው. በመጓጓዣ ጊዜ, የኬብሉን ጫፎች ከእርጥበት ለመጠበቅ, በ BOPP እራስ-ተለጣፊ ቴፕ እና ሀይግሮስኮፒክ ባልሆኑ እንዘጋቸዋለን.

እቃዎቹ በሚቀበሉበት ጊዜ እንደ የተበላሹ ማሸጊያዎች እና የምርት ገጽ መበላሸት የመሳሰሉ የጥራት ችግሮች ካሉ, እቃዎቹ እውነት መሆናቸውን ከተረጋገጠ, እቃዎቹ ከትእዛዙ ጋር አይዛመዱም, እና በመጫን ጊዜ በደንበኛው የተገኙ የጥራት ችግሮች, የመዘርጋት እና የአጠቃቀም ሂደት የምርቱ ጥራት ችግሮች እንደሆኑ ተረጋግጠዋል, ማቅረቡ በውሉ መስፈርቶች መሰረት ካልሆነ, አባክሽን ኩባንያችንን ያነጋግሩ በቀጥታ.