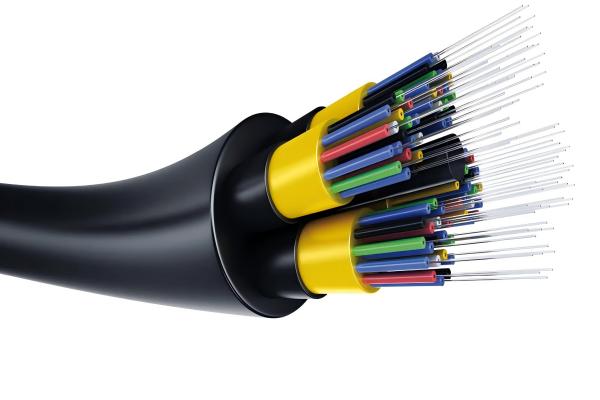

Fiber optic cables have become the backbone of modern telecommunications, offering high-speed data transmission over long distances with minimal signal loss. Understanding the materials used in their production is essential for grasping the effectiveness, durability, and adaptability of these cables across various applications. In this article, we explore the key fiber optic materials that contribute to the production of a fiber optic cable, analyzing their characteristics, roles, and the latest innovations in this field.

1. Core Materials: The Heart of Optical Transmission

The core of a fiber optic cable is its most vital component, responsible for transmitting light signals. El choice of core material directly affects the performance of the cable in terms of data transmission speed, efficiency, and signal loss.

1.1. Silica (SiO₂)

The primary material used for the core in most fiber optic cables is high-purity silica glass (SiO₂). Silica is chosen for its excellent optical properties, inclòs:

- Low Attenuation: Silica exhibits minimal signal loss, enabling long-distance data transmission.

- High Bandwidth: It supports a wide range of wavelengths, providing higher data-carrying capacity.

- Temperature Resistance: Silica’s ability to withstand high temperatures makes it ideal for harsh environments.

Variations in Silica Composition:

- Pure Silica Cores: Commonly used in single-mode fibers (e.g., G652D), offering lower attenuation and suitable for long-distance communication.

- Doped Silica Cores: Adding dopants like germanium or phosphorus modifies the refractive index, enhancing performance in multimode fibers.

1.2. Fluoride Glasses

Fluoride glasses (e.g., ZBLAN) are specialized materials used in certain optical fibers, primarily for applications requiring transmission in the mid-infrared range. These materials offer lower dispersion and are used in specialty applications such as medical lasers and military communications.

1.3. Plastic Optical Fibers (POF)

Plastic Optical Fibers use polymethyl methacrylate (PMMA) or other polymers for the core. While they have higher attenuation compared to silica-based fibers, they are more flexible, easier to handle, and are suitable for short-distance communication, such as in home networks and automotive systems.

2. Cladding Materials: Ensuring Signal Confinement

The cladding layer surrounds the core and plays a crucial role in maintaining the integrity of light transmission by reflecting light back into the core through the principle of total internal reflection.

2.1. Silica Cladding

Silica is also commonly used for the cladding material, but with a slightly lower refractive index than the core. This difference in refractive index is what keeps the light confined within the core, enabling efficient signal transmission.

2.2. Polymer Cladding

In plastic optical fibers, the cladding is typically made from fluorinated polymers. These polymers offer:

- Flexibility: Ideal for applications requiring bendable fibers.

- Durabilitat: Resistant to chemicals and environmental factors.

3. Coating Materials: Protection and Durability

Coating materials are applied to the cladding to protect the fiber from physical damage and environmental factors like moisture and temperature fluctuations.

3.1. Acrylate Coatings

Acrylate coatings are the most widely used for fiber optics due to their excellent protection and flexibility. The primary types include:

- Primary Coating: A soft, buffer layer that cushions the fiber, protecting it from micro-bending losses.

- Secondary Coating: A tougher layer that provides additional mechanical strength.

3.2. Polyimide Coatings

Polyimide coatings are used in environments that require higher temperature resistance. These coatings can withstand temperatures exceeding 300°C, making them suitable for military, aeroespacial, and industrial applications.

3.3. Silicone Coatings

Silicone-based coatings offer excellent flexibility and resistance to extreme temperatures. They are particularly useful in medical applications where the fiber needs to be highly flexible and biocompatible.

4. Buffer Materials: Enhancing Mechanical Strength

Buffers are additional layers applied over the coated fiber to provide extra protection against physical stress and environmental exposure.

4.1. Tight Buffer

A tight buffer is a single-layer protective coating, usually made of thermoplastic materials like clorur de polivinil (PVC) or nylon. It is directly applied to the fiber and is commonly used in indoor cables where flexibility and easy handling are necessary.

4.2. Loose Tube Buffer

In outdoor and long-distance cables, a loose tube buffer, typically made from polyethylene (PE), is used. The fiber optic strands are placed in a gel-filled or dry-core loose tube, which helps to protect against moisture ingress and temperature changes.

5. Strengthening Materials: Ensuring Cable Integrity

To maintain structural integrity and prevent fiber breakage, various strengthening materials are incorporated into the design of fiber optic cables.

5.1. Aramid Yarn (Kevlar)

Aramid yarn, commonly known as Kevlar, is used to provide tensile strength and protect the fibers from physical stress during installation. Kevlar is lightweight, flexible, and resistant to stretching, making it an ideal reinforcement material.

5.2. Steel Wire

In some heavy-duty fiber optic cables, steel wires are included as strength members. They provide additional mechanical support, especially in environments where the cable is subject to heavy loads or harsh conditions, such as underwater or aerial installations.

5.3. Fiberglass Rods

Fiberglass rods are another form of strengthening material used to provide rigidity and support to the cable, particularly in armored fiber optic cables designed for rugged environments.

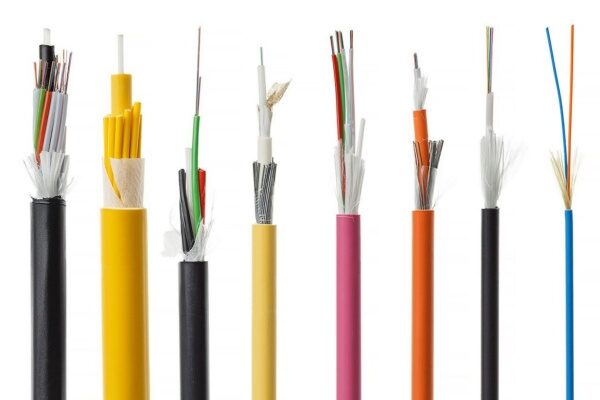

6. Outer Jacket Materials: Shielding Against External Factors

The outer jacket is the protective covering that shields the internal components of the fiber optic cable from external damage. The material used for the outer jacket depends on the intended application and environmental conditions.

6.1. Clorur de polivinil (PVC)

PVC is one of the most common outer jacket materials, known for its:

- Durabilitat: Resistant to abrasion and chemicals.

- Flexibility: Easy to install in various environments.

- Cost-Effectiveness: Affordable option for standard applications.

6.2. Polietilè (PE)

Polyethylene offers excellent resistance to moisture, making it a popular choice for outdoor cables. It also provides better performance in harsh weather conditions compared to PVC.

6.3. Baix fum zero halògens (LSZH)

LSZH materials are used in environments where fire safety is a priority, such as in public buildings, túnels, and aircraft. LSZH jackets do not emit harmful halogen gases when burned, reducing the risk of toxic fumes.

6.4. Thermoplastic Polyurethane (TPU)

TPU is known for its high abrasion resistance and flexibility. It is often used in industrial and military applications where the cable might be subject to physical stress or extreme environmental conditions.

7. Additional Protective Materials: Armoring and Waterproofing

For cables used in challenging environments, additional layers like armoring and waterproofing are included to enhance durability.

7.1. Armored Layers

Armored fiber optic cables have an extra layer of protection made from steel or aluminum tape. This provides enhanced mechanical protection against rodents, heavy loads, and other physical damage. Armored cables are commonly used in direct burial applications and industrial settings.

7.2. Water-Blocking Materials

Water-blocking gels or tapes are incorporated into the design of outdoor fiber optic cables to prevent water ingress. The materials used include:

- Thixotropic Gel: A jelly-like substance that fills the loose tube, protecting the fibers from moisture.

- Water-Swellable Tapes: Special tapes that expand upon contact with water, sealing any potential entry points.

8. Innovations in Fiber Optic Materials

The fiber optic industry is continuously evolving, with ongoing research aimed at improving performance, durability, and sustainability.

8.1. Advanced Polymer Coatings

New polymer coatings are being developed to enhance fiber performance in extreme conditions. For instance, UV-cured acrylate coatings are designed to offer better protection against UV radiation and chemical exposure.

8.2. Biodegradable Materials

With the increasing focus on environmental sustainability, researchers are exploring biodegradable materials for certain components of fiber optic cables, particularly in non-critical applications where short-term use is expected.

8.3. Composite Materials

Composite materials combining different polymers and reinforcement elements are being introduced to enhance the mechanical properties of cables, making them lighter, stronger, and more resistant to external factors.

The production of fiber optic cables involves a complex interplay of various materials, each chosen for its specific properties to ensure efficient, reliable, and durable performance. From the core materials like high-purity silica that carry the data, to the outer jackets and coatings that protect against physical and environmental damage, every component plays a crucial role in the overall functionality of the cable.

As technological advancements continue, we can expect to see further innovations in fiber optic materials, focusing on enhancing data transmission speeds, increasing durability, and promoting environmental sustainability. Understanding these materials and their roles is fundamental for anyone looking to explore the world of fiber optic communication, whether for telecommunications, medical applications, or industrial use.

By keeping an eye on the latest developments and material innovations, industries can optimize their fiber optic solutions, paving the way for more efficient and sustainable communication networks in the future.