MARINE & OFFSHORE CABLES

VERI Cables offers a full range of marine, offshore, and shipboard cables to different standards for the offshore oil and gas, ship, and marine industries.

- NEK606 Standard Marine and Offshore Cables

- IEC60092 Standard Marine and Offshore Cables

- BS 6883 and BS 7917 Standard Ship and Offshore Cables

- JIS C 3410 Marine Cables

Sold year-round with professional technical support and at competitive prices, these ranges include power and control cables, instrumentation and control cables, LAN data, and communication cables by IEC-60332 and IEC-60331, as well as flame retardant and fire-resistant versions such as RFOU and BFOU NEK 606. Bureau Veritas is one of the world’s leading classification societies and offshore verification organizations dedicated to ship and offshore cables. Veritas is one of the world’s leading classification societies and offshore verification organizations dedicated to the safety and efficiency of power transmission on board ships and at sea, and our products have received third-party certification from BV.

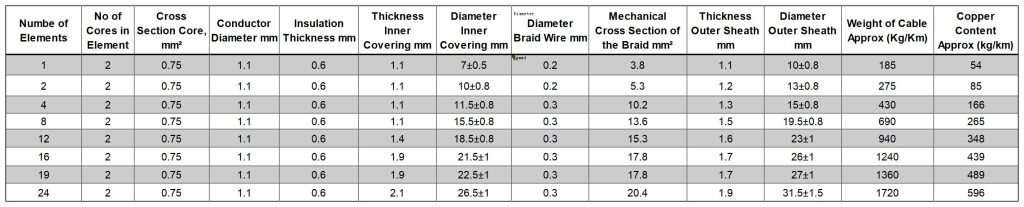

NEK606 Ship and Offshore Cables

Ang NEK606 standard is based on industrial and technical specifications for low, medium, and high voltage power, instrumentation, and control cables commonly used in Norway, and is an internationally recognized standard for marine cables. The cables are manufactured to be complex and robust and are fully capable of withstanding the harsh environments and hazardous areas of oil and gas extraction. The standard also adopts test methods for hydrocarbon (HC), fire-resistant cables, and jet-fire (JF) resistant cables, and further specifies requirements for oil and mud resistance for installation on mobile and fixed offshore installations.

For detailed information or order requirements, please feel free to contact us.

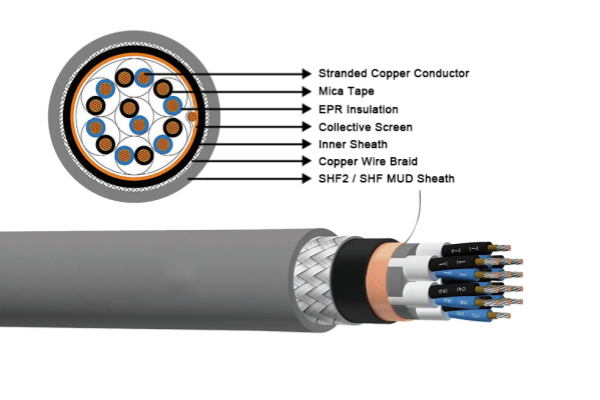

BFOU 0.6/1kV Offshore Cable

Voltage Rating Uo/U: 0.6/1kV

Test Voltage: 3.5kV

Temperature Rating: -40°C to +90°C

Minimum Bending Radius: 8 x overall diameter

MGA STANDARDS: NEK 606 P5/P12, IEC 60092-353, EN 60228

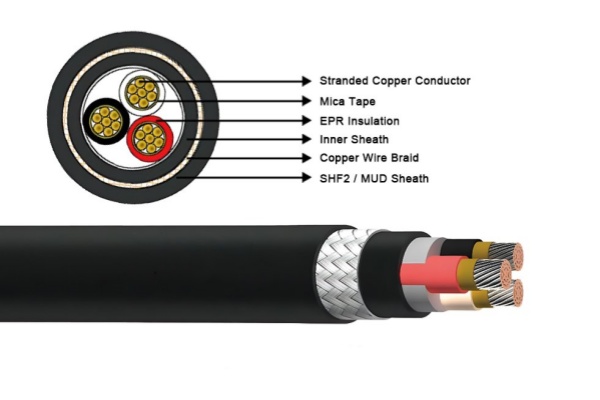

RFOU 0.6/1KV Power Cable

Voltage Rating Uo/U: 0.6/1kV

Test Voltage: 3.5kV

Temperature Rating: -40°C to +90°C

Minimum Bending Radius: 8 x overall diameter

STANDARDS NEK 606, IEC 60092-350, IEC/EN 60228

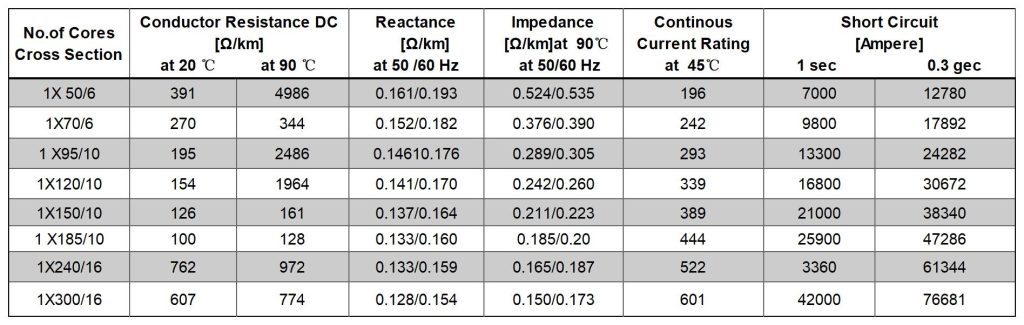

IEC60092 Ship Offshore Cables

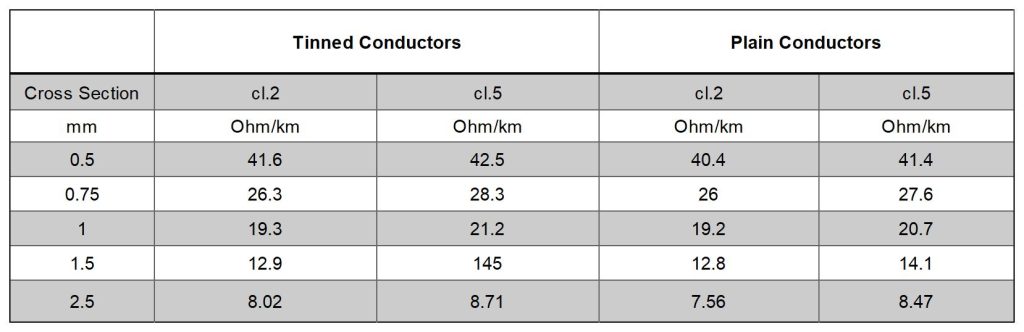

The IEC 60092 standard is also one of the popular models for offshore marine cables and covers power instrumentation cables for use in mobile marine environments. Copper conductors are used for electrical systems up to 18/30(36) kV on board ships and at sea for mobile or fixed installations. Includes systems subject to vibration or movement of ships and equipment and is not suitable for frequent bending.

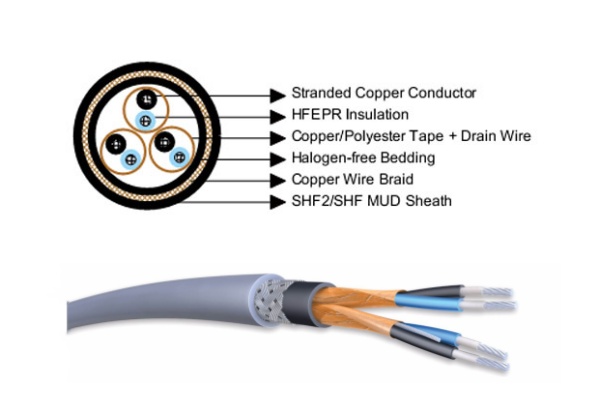

Konduktor: Copper Conductor

Pagbulag: EPR

Bedding: Halogen Free Mud Resistant Bedding

Armouring: Tinned copper wire braid

Sheath: Mud-resistant sheath

Voltage Rating: Power Cable 600/1000 Volts / Instrumentation Cable 150-250 Volts

Temperature Limits: -40°C (fixed installation) to +90°C

IEC 60092-350: Fixed electrical systems applicable to ships and fixed/mobile offshore installations with rated voltages up to 18/30(36) kV.

IEC60092-352: For fixed electrical systems on board ships with rated voltages up to 15kV.

IEC60092-353: Extruded solid insulated non-radial power cables for fixed installations with rated voltages between 1kV and 3kV, including cables for maintaining normal power transmission during fire.

IEC 60092-376: Shielded and unshielded cables, suitable for control and instrumentation circuits on ships and fixed/mobile offshore installations, with extruded solid insulation, rated at 150/250V.

Popular BFOU & RFOU Features

Cables for marine and offshore are often named by many acronyms to identify the properties of the cable itself. Pananglitan, in the case of the BFOU and RFOU types of cables, the “B” denotes the insulation and sheath material, and the sheath is a flame-retardant variant of the halogen-free Ethylene Propylene Rubber (EPR) used in the RFOU cables. “F” refers to the flame retardant, halogen-free thermoset compound in the cable’s construction material. “O” refers to tinned annealed copper braid, a common material for cable conductors. “U” refers to flame-retardant, halogen-free, mud-resistant thermosetting compounds, commonly used standard SHF2 (IEC 60092-360, 60092-360).

VERI high voltage offshore marine cables can be used in extreme high and low temperatures and are resistant to the adverse elements of moisture, lana, acid, mud, and saltwater common in marine and offshore operating environments. Our cables are manufactured to a range of British Standards including BS6883 (Fixed wiring on ships and mobile and fixed offshore installations), BS7655 (Marine wiring, pagbulag, and sheathing materials for offshore applications), ug BS7917 (Fire-resistant cables for mobile and offshore fixed wiring on ships), with customization services available to specific standards.

Excellent Water Resistance

Our offshore cables incorporate a range of specialized compounds with water-resistant materials, greatly reducing the likelihood of water ingress into the cable during use. As we all know, the flow of water in a "leaky" state is a very dangerous factor, and the water resistance of the cable material is an important criterion for you to choose a quality cable, so VERI Offshore Cable is your first choice due to its excellent water resistance.

Integrated Cable Production

Our cables are produced in a professional integrated production line, from grinding, stranding, and winding of copper and aluminum conductors to the final packaging and trucking, all completed in one production line, we are very welcome loyal customers to come to observe our production process, you can exchange ideas with our senior engineer's team, and work together to create the most qualified cable products.

VERI Manufacturing, in addition to its standard range of marine cables, designs and develops customized cables for specific offshore projects, lakip submarine electric cables capable of withstanding harsh environments and deep-sea water pressure. Having been in the business for more than 30 mga tuig, we are committed to innovation and development in the hope of providing a more comprehensive service to the power industry in line with the trend towards environmental protection.

Our Professional Services

Quality Certification

The products manufactured by VERI Cables comply with international standards such as GB, IEC, BS, NFC, ASTM, DIN, ug uban pa. Moreover, our technical team can provide cable customization services for your needs.

Customer Tracking

VERI provides free professional cable consulting services, one-stop project solution services, and fast product delivery solutions.

Professional Transportation

VERI Cables’ initial goal is to ensure fast and safe delivery of products while also providing the best packaging and transportation solutions to reduce customers’ transportation costs greatly.

Cable Packaging

VERI cable packaging is supplied in wooden reels, corrugated boxes, and coils. The ends are sealed with BOPP self-adhesive tape and non-hygroscopic sealing caps to protect the cable ends from moisture. We can print the required logo on the outside of the drums with waterproof material as per the customer’s requirement.