Optical Power Ground Wire

- It has two functions, one is as a lightning protection line for transmission lines, providing shielding protection for transmission lines against lightning strikes and discharges. The other is for video, data and various control signals to form a multi-channel broadband communication network.

OPGW fiber optic cables in overhead transmission lines generally have skeleton type, center tube type and layer stranded type. It is mainly used for lines with voltage levels of 100kV, 220kV and 500kV. It is easy to be affected by line blackout, safety and other factors, and is mostly used for new lines.

OPGW Cable More Types

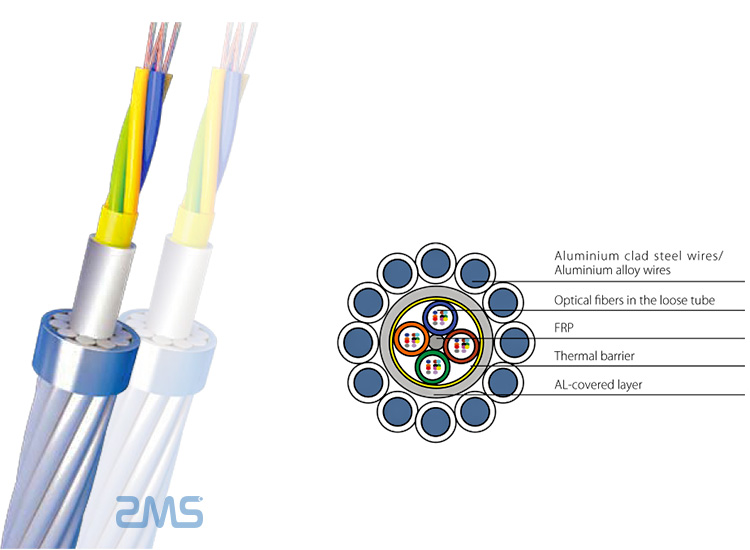

Aluminum Tube Layer Warping Core Type OPGW

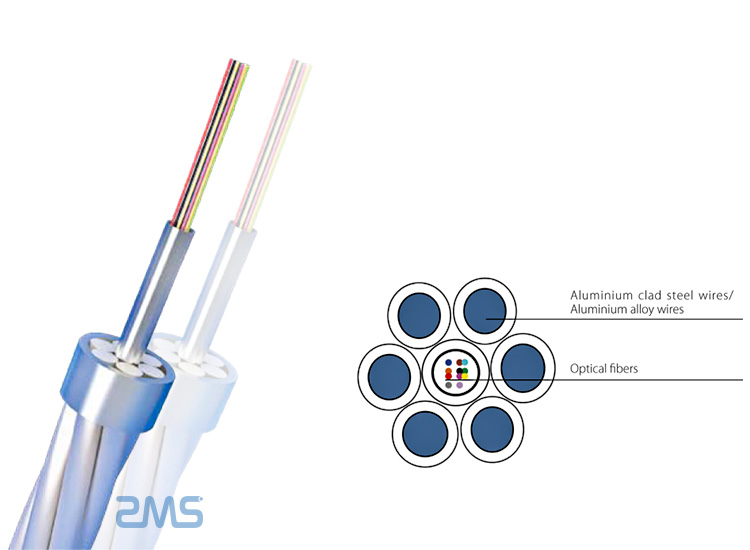

Our optical fiber is located in a PBT plastic loose tube, and the outside is covered with a seamless aluminum tube. The aluminum tube is stranded with 1 to 2 layers of monofilament, which can be all-aluminum-clad steel wire or a mixed twist of aluminum-clad steel wire and aluminum alloy wire.

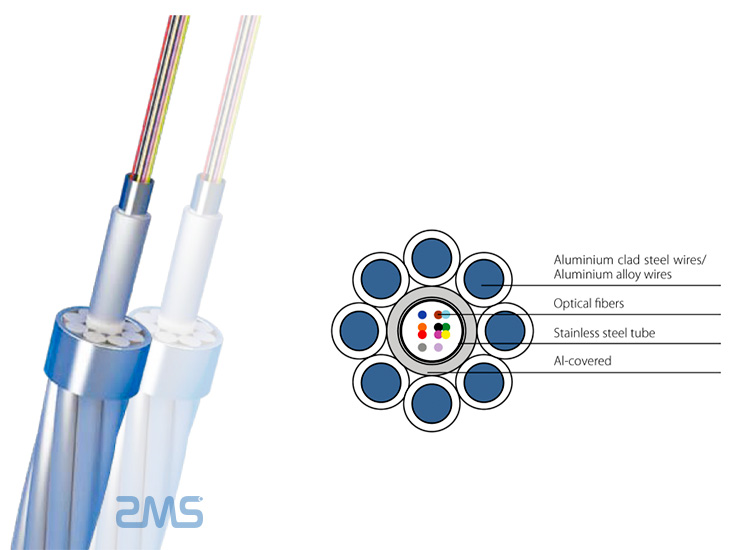

Aluminum Clad Steel Tube Structure OPGW

The optical fiber is placed in a sealed stainless-steel tube, and the outer layer is covered with an aluminum layer to form an optical fiber unit. The aluminum-clad stainless-steel pipe is stranded with 1 to 2 layers of monofilament.

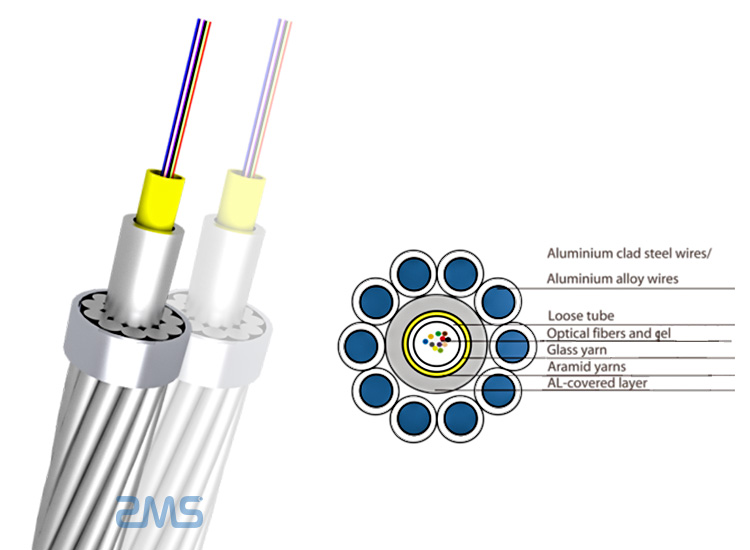

Aluminum Tube Center Tube Type OPGW

This fiber optic product is housed in a PBT plastic loose sleeve over a seamless aluminum tube.

The aluminum tube is stranded with 1 neu 2 layers of monofilaments, which can be all aluminum-clad steel wire or a mixture of aluminum-clad steel wire and aluminum alloy wire.

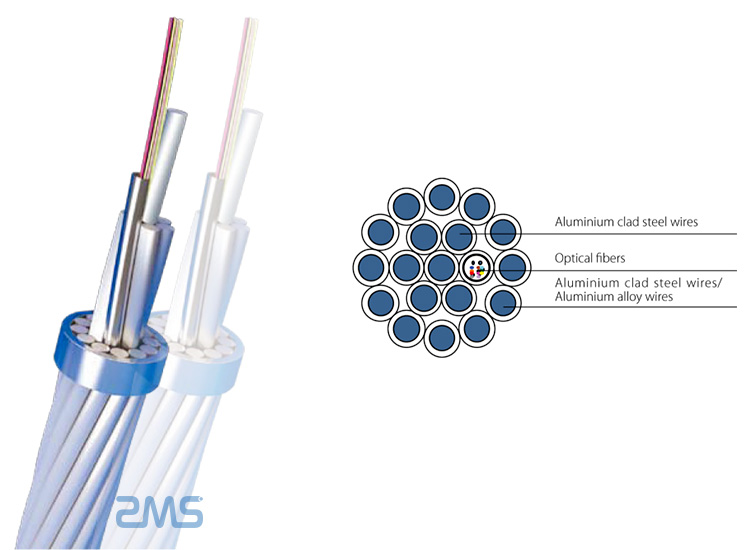

Rust Steel Tube Structure OPGW - Layer Stranded

The stainless-steel tube is twisted with 2 to 3 layers of aluminum-clad steel wire, or the aluminum-clad steel wire and aluminum alloy wire are twisted together, which can accommodate single or multiple optical units.

Stainless Steel Tube Structure OPGW - Center Type

The center stainless-steel tube is twisted with 1 to 2 layers of monofilament, which can be all-aluminum-clad steel wire or a mixed-stranded aluminum-clad steel wire and aluminum alloy wire.

Product Description

Structure Material

Core: Quartz Glass

Loose Tubing: Polyester or High Strength Plastic

Metal reinforcement: stainless steel tube, aluminum clad steel wire

Conductive material layer: aluminum alloy wire, aluminum clad steel wire

Sheath: high-density HDPE, metal layer

Filler: waterproof paste or expansion powder

Armor layer (optional): steel belt or aluminum belt armor

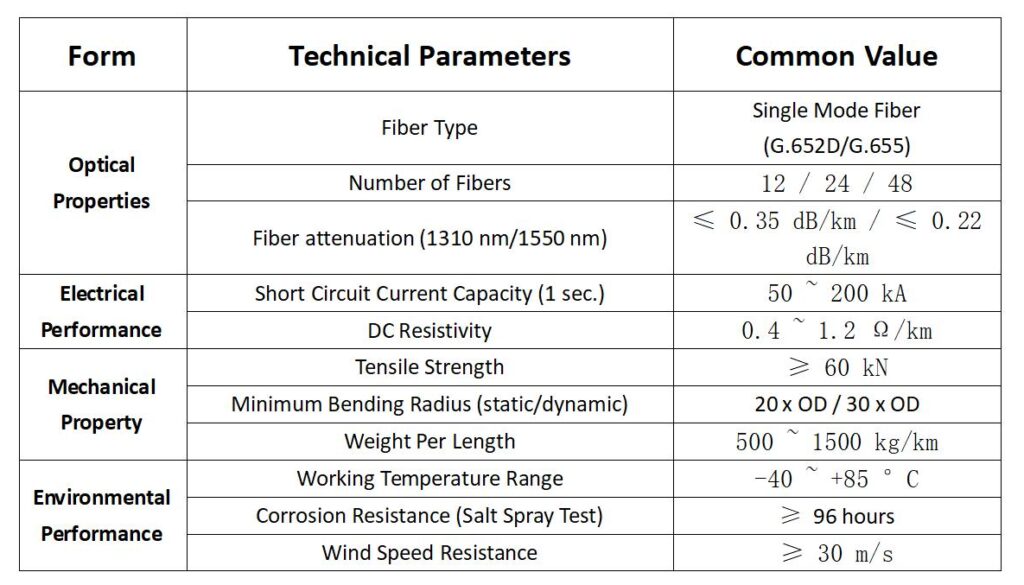

Technical Specification Parameters

Safonol

IEC 60793, IEC 60794, ASTM B232/B232M, IEC 62271 and etc.

Length & Maint

Recommendations and customization can be provided according to the different needs of each client.

Key Features of OPGW Cables

VERI OPGW cables are mainly used in communication, monitoring, and data transmission of power transmission lines, which can effectively improve the safety, stability, and intelligence of the power system.

- Safe and reliable: OPGW fiber optic cable’s good insulation performance and anti-interference ability can effectively ensure the safe and stable operation of the power system.

- Energy saving and environmental protection: the use of fiber optic cable to transmit signals, reduce the use of copper wires in the power system, and reduce energy consumption and environmental pollution.

- Convenient maintenance: OPGW fiber optic cable maintenance and management is relatively simple, greatly reducing maintenance costs and workload.

- Large communication capacity: OPGW power fiber optic cable can realize high-speed, large-capacity communication transmission, suitable for a variety of application scenarios in the power system.

Generally, the number of optical fibers of OPGW fiber optic cable will depend on the specific needs, a the common specifications are 24 creiddiau, 36 creiddiau, 48 creiddiau, and so on. The more the number of optical fibers, the stronger the communication ability of the cable.

OPGW Cable Diameter: The diameter of OPGW fiber optic cable is an important parameter affecting its installation and laying. The smaller the diameter of the fiber optic cable, the less space, and resources required for installation, while also reducing the impact on existing facilities. Existing facilities. Felly, when selecting optical ground wires, it is necessary to consider the diameter of the cable to match the actual laying conditions. OPGW cables need to be considered when selecting cables for laying.

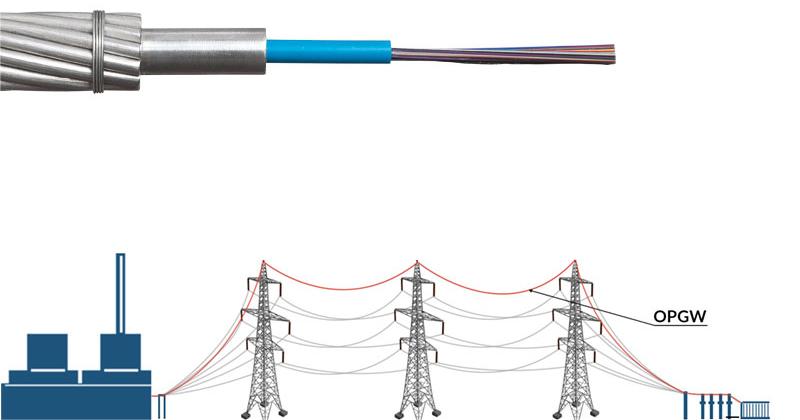

Applications of OPGW Cables in Power Systems

OPGW optical cable can be directly installed as an overhead ground wire on the ground wire hanging point of any span power tower. The specially designed OPGW optical cable can directly replace the overhead ground wire of the original high-voltage line without replacing the original tower head.

The construction of the optical wire communication system with the high-voltage line can save the construction cost of the optical cable and reduce the cost of the communication project. Mae diamedr y cebl yn fach, and the weight is light, will not bring a large additional load to the tower, with an operating temperature of -40 —70 ℃

Transportation with Professional Service

VERI Cable company has multiple ways to protect your cables, sturdy and professional shipping packaging, and comprehensive insurance. Before shipping, our cables are packaged in wooden reels and corrugated box coils. During transportation, to protect the cable ends from moisture, we seal them with BOPP self-adhesive tape and non-hygroscopic. In addition to the cables mainly introduced on this page, we also have ADSS cable (All Dielectric Self Supporting), and OPGW cable accessories, if you have cable purchase needs, you can check the vericable website or email us, and we will have a professional cable sales representative to serve you.

As professional OPGW cable suppliers, we support customized to your requirements. High-quality material at a low price and comprehensive OPGW installation services for you. Please feel free to cysylltwch â ni.

With VERI Cable, you are hiring a team of experienced engineers who carefully analyze each customer’s application and then customize the product to best suit those needs. Our resources are available for on-site training and installation supervision to ensure your cables operate reliably for years to come.