Solar Cable

VERI Cable manufactures high-quality solar cable, which ensures it meets your special applications. As a professional power cable supplier, all of our cable products have GB, ISO, ASTM, AS, BS, CSA, DIN, IEC standards, and other international standards. Many types of wire and cable address the requirements of solar power generation, transmission, and distribution. With our extensive line of different voltage cable products, the general cable offers a complete solar energy solution. And our solar cables have also contributed to some hot area’s solar generation plants. Over the years, we have exported cables to many countries. And we will give the best solar cable price for you. So, welcome to contact us now.

Solar Cable Description and Specifications

Solar Power Cable

Solar power cables are widely used indoors and outdoors. And solar photovoltaic power sources usually require isolating switches or installation. Generally, they are rated for a temperature range of -40 degrees to 90 degrees. The maximum allowable DC voltage for most solar cables is 1.8kv. Because the solar power cable is flexible and is wrapped with a metal mesh. So they can avoid high voltage and improve shielding.

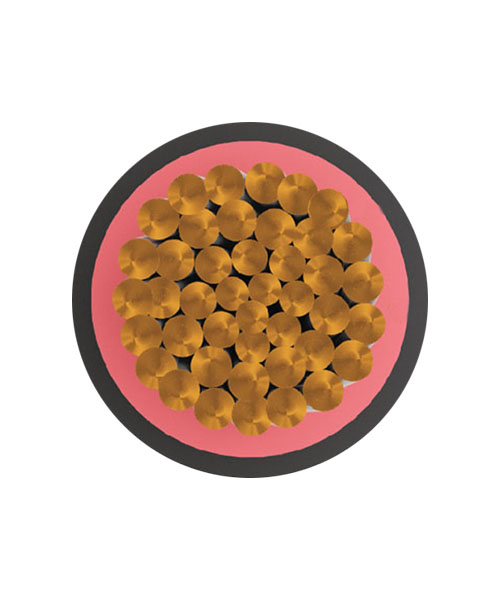

- Conductor: Flexible stranded tinned copper conductor

- Insulation: XLPE

- Sheath: XLPE / PVC / Customized

STANDARDS&REFERENCES:TUV 2PfG 1169/ IEC, TUV 2PfG 1990/ IEC standard

Application

These cables are designed for connecting photovoltaic system components inside and outside of buildings and equipment with high mechanical requirements and extreme weather conditions.

Solar power cables are mainly used for photovoltaic power generation. Then they are intended for use in photovoltaic power supply systems. And similar applications as a free hanging, movable, fixed installation. And they are buried in the ground. ZMS solar cables are always used for indoor, outdoor, hazard explosion areas, industry, or agriculture. They are suitable for applications in equipment with protective insulation.

Product Parameters

NO. OF CORES ×NOMINAL CROSS SECTION | NO. OF STRANDING | NOMINAL CONDUCTOR DIAMETER | NOMINAL INSULATION THICKNESS | NOMINAL SHEATH THICKNESS | NOMINAL OVERALL DIAMATER | NOMINAL WEIGHT |

NO. ×MM² | – | MM | MM | MM | MM | KG/KM |

1×1.5 | 30/0.25 | 1.58 | 1.14 | 0.82 | 5.4 | 52 |

1×2.5 | 50/0.25 | 2.04 | 1.14 | 0.82 | 5.8 | 67 |

1×4.0 | 56/0.30 | 2.59 | 1.14 | 0.82 | 6.4 | 87 |

1×6.0 | 84/0.30 | 3.17 | 1.14 | 0.82 | 7.0 | 113 |

1×10 | 78/0.40 | 4.07 | 1.52 | 0.82 | 8.6 | 178 |

1×16 | 128/0.40 | 5.22 | 1.52 | 0.82 | 9.8 | 254 |

1×25 | 199/0.40 | 6.51 | 1.52 | 0.82 | 11.1 | 363 |

1×35 | 279/0.40 | 7.71 | 1.52 | 0.82 | 12.3 | 473 |

Advantages

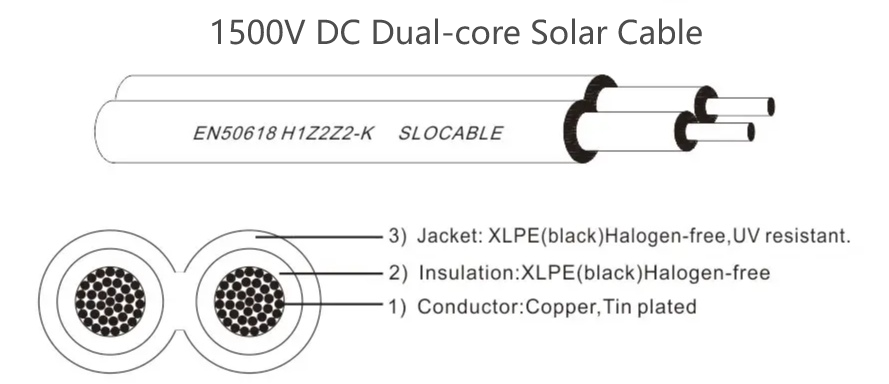

·Dual wall insulation. Electron beam cross-linked

·Excellent resistance to U.V, oil, greases, oxygen and ozone

·Excellent resistance to abrasion

·Halogen free, flame retardant, low toxicity

·Excellent flexibility and stripping performance

·High Voltage and Current carrying capacity

·TUV, CE approved

PV1-F 1.5mm2 XLPE Insulation Solar Cable

Rated temperature: -40 Degree to +90 Degrees

Voltage test on complete cable: 6.5KV AC ,15KV DC ,5min

The max temperature at conductor: +120 Degree

The expected period of use is 25 years (Ambient temperature-40+90Degree)

The permitted short circuit temperature refers to the period of 5s is +200 Degree

Bending radius: ≥4*Φ(D<8mm)≥6*Φ(D≥8MM)

Resistance against acid and alkaline solution: EN 60811-2-1

Cold bending test: EN60811-1-4

Ozone resistance at the complete cable: EN50396

Fire test: IEC 60332-1

Product Parameters

| Cross Section | Conductor Construction | Conductor Stranded O.D (MM) | Insulation I.D.(mm) | Jacket OD.(mm) | Conductor MAX Resistance |

| 1.5 | 30/0.25 | 1.58mm | 2.9 | 4.5 | 13.7 |

| 2.5 | 49/0.25 | 2.02mm | 3.4 | 5.0 | 8.21 |

| 4.0 | 56/0.30 | 2.60mm | 3.9 | 5.5 | 5.09 |

| 6.0 | 84/0.30 | 3.42mm | 4.7 | 6.5 | 3.39 |

| 10.0 | 84/0.40 | 4.56mm | 6.2 | 8.0 | 1.95 |

The Features of Solar Power Cable

First, solar power cables are often exposed to sunlight, and solar systems are often used for harsh environmental conditions. Such as high temperatures and ultraviolet radiation. Now, the variety of materials are PVC, rubber, and high-quality cross-link materials.

Second, solar cables are flexible and design for fixed and mobile installations. About inside the outer casing of the solar cable, the positive and negative cables are double insulated.

And they run completely separate from each other. Then it reduces the risk of signal interference and further protects the quality. With this precaution, the likelihood of ground faults and short circuits is greatly reduced, improving the overall safety and efficiency.

And they are designed to withstand UV rays and weather and install outdoors without any problems. In fact, most of the time these cables are used outdoors. And they are exposed to harsh sunlight and harsh environments. Because of the shielding and casing on the solar cable, the wiring can run without the risk of electrical quality. Or the signals passing through the wires.

Excellent Service of VERI Cable

Export Experience

As a professional cable manufacturer, our cable products have been exported to many countries in the past 30 years, including the USA, Canada, Spain, UK, Germany, France, Russia, Greece, Saudi Arabia, etc. In these countries, our cable products are very popular with customers. And every year, because of our good quality and service, we would receive much good feedback from our customers.

Customized Cable Service

Our range of custom services includes design, size, and surface color. Many popular colors are also available for you to choose. We also specialize in over-sheathing, for example, we can make custom Polyethylene (PE) and Polyurethane (PUR) according to your requirements. We can provide solutions based on your ideas. Please contact us to give us your idea.

Strict Quality Inspection Standards

VERI Cable offers a wide variety of power cables based on trends and personal preferences. And we provide all kinds of power cables, more than 100 series. Then, to ensure the quality of the cables, we insist on testing our products once in a while.