Câble optique de fibre d'exploitation

Alors que l'utilisation de la fibre optique dans l'industrie minière augmente rapidement, En plus de l'excellente qualité des câbles à fibre optique miniers des fabricants de câbles Veri, Nous vendons un large éventail d'autres câbles tels que câbles sous-marins, câbles aériens, câbles coaxiaux, Câbles HTLS, et d'autres câbles de haute qualité. Le succès de l'exploitation minière aide également à favoriser la confiance dans l'applicabilité de la fibre optique aux autres applications environnementales durs. Nous pouvons également fabriquer des câbles et des câbles en fonction des exigences du client, Alors n'hésitez pas à Contactez-nous Si vous avez besoin.

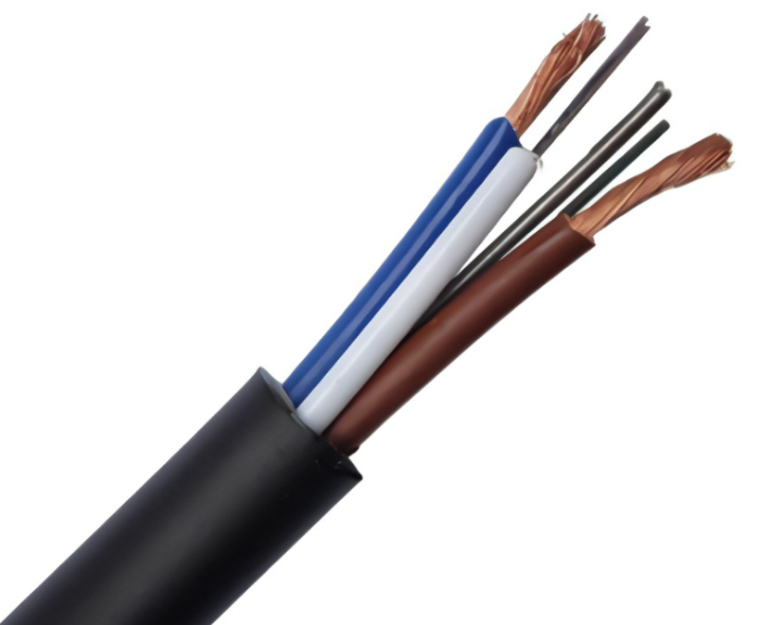

Câble à fibre optique composite photoélectrique OPLC

Données Câble composite photoélectrique (OPLC) est de placer l'unité de câble optique minier protégé dans le câble d'alimentation, qui peut être utilisé dans les systèmes d'alimentation avec des tensions nominales de 0,6 / 1kV et en dessous. Il intègre la fibre optique, fil de cuivre de transmission, et fil de signal en cuivre. Accès haut débit, consommation électrique de l'équipement, transmission de signaux d'urgence, et d'autres problèmes.

En raison de la diversité des méthodes d'accès et de la complexité de l'environnement d'utilisation, les fabricants peuvent également personnaliser selon les exigences du client, selon différentes tensions, différents noyaux de fibres, et différentes structures pour assurer la sécurité et la fiabilité du réseau.

Caractéristiques de la fibre optique OPLC

- Il ne nécessite pas de pylône séparé car il peut être installé sur la même tour que les lignes électriques..

- La construction peut être réalisée sans coupure de courant car la panne de la ligne électrique n'affectera pas la transmission normale du câble optique..

- Structure non métallique, donc bonne performance d'isolation, et protection contre la foudre.

- Le processus de production est sophistiqué, le fil d'aramide est uniformément sollicité et présente d'excellentes performances contrainte-déformation.

- Le diamètre du câble est petit, le poids est léger, la portée peut atteindre 1500M, et la charge supplémentaire sur la tour est faible.

- La résistance à la traction est grande, qui peut dépasser 90KN, et la performance anti-corrosion électrique est bonne.

- Il a d'excellentes performances anti-frappe et peut s'adapter aux conditions climatiques difficiles.

Application du câble optique OPLC

- Les câbles composites photoélectriques sont généralement utilisés dans les systèmes basse tension 0,6/1KV;

- IPTV, accès Internet;

- Téléphone multimédia, communication vocale, compteur intelligent domestique, etc.;

- Le raccordement de la salle des équipements de communication optique, support de distribution optique, instruments, et autres équipements.

- Le câble est utilisé pour la communication dans les mines de charbon, mines d'or, mines de minerai de fer, et autres applications minières.

- Conduit/Aérien/Direct Enterré.

Câble optique composite photoélectrique OPGW

La fibre optique est posée sur le fil de terre de la ligne de transmission à haute tension au-dessus pour former un réseau de communication de fibre optique sur la ligne de transmission.

Cette structure a les doubles fonctions de fil de terre et de communication et est généralement appelé Fibre OPGW, Parce que cette fibre résiste aux interférences électromagnétiques, poids de poids, et peut être installé sur le dessus de la tour de ligne de transmission sans considérer l'emplacement d'installation optimal et la corrosion électromagnétique.

Donc, OPGW a les caractéristiques d'une haute fiabilité, propriétés mécaniques supérieures, et à faible coût.

Cette technique est particulièrement utile et économique lors de la pose ou du remplacement des fils de terre existants.

Caractéristiques du câble optique OPGW

- Il convient à haute tension lignes de 110kV et plus, facile à entretenir, et facile à résoudre le problème de la ramification, et ses propriétés mécaniques peuvent répondre aux besoins des lignes de grande portée. Et OPGW adopte une armure métallique, qui n'a aucun effet sur la corrosion et le vieillissement à haute pression. Depuis le OPGW doit être éteint pendant le processus de construction, La perte de puissance est importante. Donc, OPGW devrait être utilisé pour les nouvelles lignes haute tension supérieures à 110KV.

- Dans l'indice de performance de OPGW, plus le courant de court-circuit est important, Plus les bons conducteurs doivent être utilisés, et la résistance à la traction diminue également. Dans le cas d'une certaine résistance à la traction, la capacité de courant de court-circuit doit être augmentée. La simple augmentation de la section transversale du métal entraîne une augmentation du diamètre et du poids du câble., Créer des problèmes de sécurité pour la force de la tour.

Application du câble optique OPGW

Construction urbaine

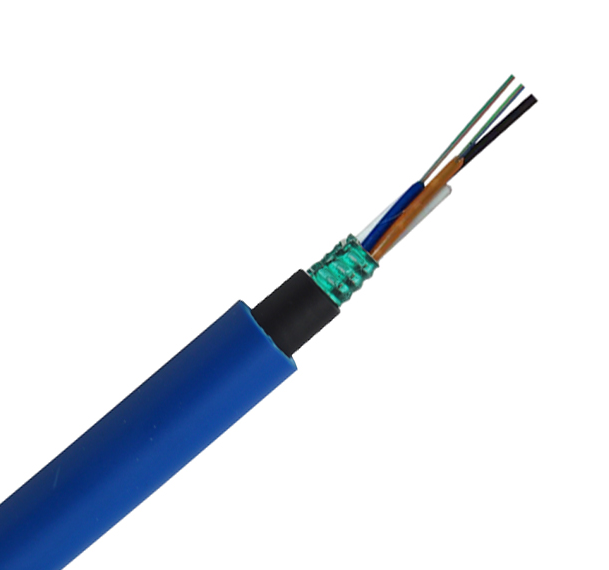

MGTSV Mine Flame istruant Optical Cable

La structure de MGTSV Le câble optique doit mettre 250 μm de fibre optique dans un tube lâche en matériau module élevé, et le tube lâche est rempli d'un composé imperméable.

Le centre de l'âme du câble est une âme de renfort métallique, autour duquel le tube lâche (et corde de remplissage) sont tordues en un noyau de câble compact et rond, et les lacunes dans le noyau du câble sont remplies de charges de blocage d'eau.

Ruban en acier plastifié double face (PSP) est enveloppé longitudinalement pour extruder une gaine intérieure en polyéthylène, et une gaine externe en polyéthylène est extrudée à l'extérieur de la gaine intérieure pour former un câble.

Caractéristiques du câble optique MGTSV

- Bonnes propriétés mécaniques et caractéristiques de température dues à l'utilisation d'un seul armature centrale.

Le tube libre est rempli d'un composé imperméable spécial, et le matériau de tube en vrac lui-même a une bonne résistance à l'eau pour empêcher les infiltrations d'eau du câble optique. Et l'intérieur du tube est rempli de pommade spéciale, qui joue un rôle clé dans la protection de la fibre optique. Et il a également une bonne résistance à la compression et une douceur. - Utilisez du ruban en acier à revêtement en plastique double face (PSP) Pour améliorer la perméabilité anti-humidité du câble optique, et en même temps, il a la fonction d'un anti-rat. De plus, La gaine secondaire est en PVC ignifuge bleue, ce qui fait que le câble optique a un bon effet ignifuge à la flamme.

Application du câble optique MGTSV

- Il convient aux mines de charbon, mines d'or, Mines de fer et autres occasions minières, ainsi que les arbres de tunnel, routes, et d'autres endroits avec des exigences issues de la flamme.

- Il convient à la communication à longue distance et à la communication entre les offres.

À propos du câble Veri

Veri est une entreprise spécialisée dans la production et le traitement des câbles de fibres optiques, câbles optiques intérieurs et extérieurs, Câbles optiques de puissance, câbles optiques spéciaux, cavaliers en fibres optiques, et autres produits. Il a un système de gestion de la qualité complet et scientifique.

Une entreprise de haute technologie qui fabrique et développe des équipements de communication optique. Les produits sont largement utilisés dans les télécommunications, mobile, Chine Unicom, radio et télévision, Grille d'État, militaire, chemin de fer, autoroute, transit ferroviaire, exploitation minière, et d'autres domaines de communication, et ont remporté des éloges unanimes pour la qualité et le service de confiance par les utilisateurs.

Les produits de l'entreprise sont conformes à l'UIT, CEI, GB/T, Yd / t, et international et Normes de qualité domestique dans l'industrie, et exécuter efficacement la certification ISO9001 Système de gestion de la qualité internationale pour s'assurer que la qualité du produit est excellente, écurie, continu, et traçable.

Les produits et les équipes techniques de la société sont des experts et des artisans de production qui sont engagés dans l'industrie de la fabrication de câbles de fibre optique depuis de nombreuses années et ont une coopération approfondie avec de nombreuses universités de communication domestique pour effectuer des échanges techniques et une recherche conjointe et le développement de produits. Si vous avez des besoins, bienvenue pour consulter.