Câble sans halogène à faible fumée

Le câble à faible fumée et sans halogène fourni par VERI cable a excellentes propriétés ignifuges, presque aucune fumée et aucun gaz corrosif ne s'échappant lors de la combustion. Ils sont largement utilisés dans les centrales nucléaires, stations de métro, centraux téléphoniques et centres de contrôle informatique, immeubles de grande hauteur, hôtels, stations de radio et de télévision, installations militaires importantes, plateformes pétrolières, et d'autres endroits densément peuplés avec une faible densité de l'air.

Le diamètre de courbure de Câble LSZH n'est pas inférieur à 15 fois le diamètre extérieur du câble, et le diamètre de courbure du câble unipolaire n'est pas inférieur à 20 fois. D'autres peuvent être personnalisés, enquête gratuite est le bienvenu.

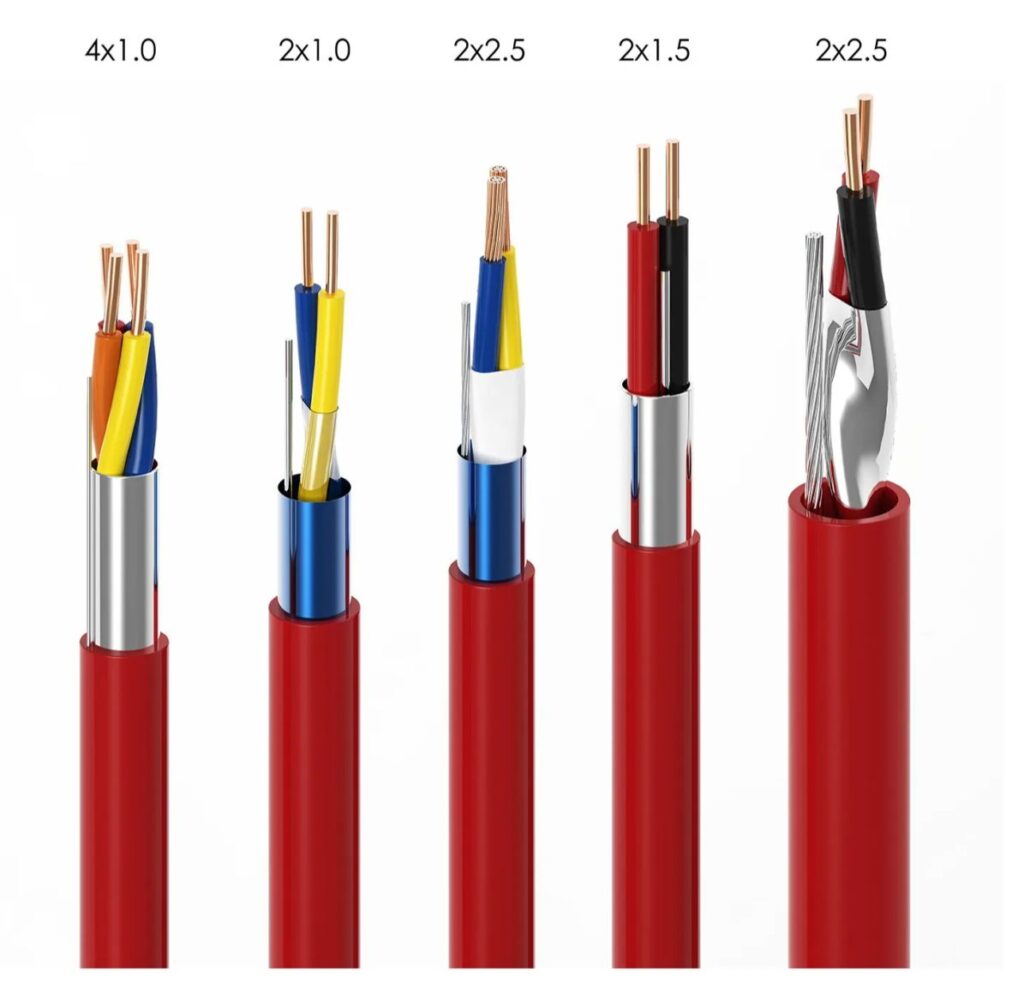

Types de câbles à faible fumée et sans halogène

Contrôle & Câbles de communication LSZH: Le faible dégagement de fumée et l'absence d'halogène sont une propriété que les câbles peuvent avoir en changeant de matériau.. Dans les câbles de commande et les câbles de communication, de nombreux câbles intègrent également des propriétés à faible teneur en fumée et sans halogène dans le matériau pour améliorer leur sécurité lorsqu'ils sont utilisés dans des lieux publics.

Le câble LSZH a donc de nombreux types de spécifications de paramètres, en fonction des fonctions que vous devez réaliser dans votre projet.

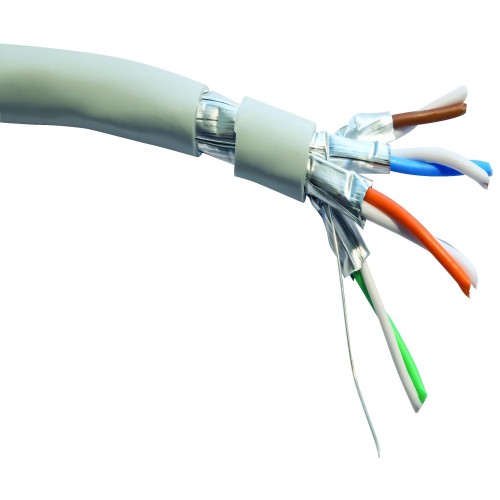

Câble LSZH Cat6

Conducteur: Classe 1 conducteur en cuivre massif

Isolation: PEHD (Polyéthylène haute densité)

Gaine: LSZH (Faible fumée, zéro halogène)

NORMES: Ignifuge selon BS EN/IEC 60332-1-2

CARACTÉRISTIQUES

Température nominale: Fixé: -20°C à +60°C

Rayon de courbure minimum: Fixé: 4 x diamètre total, Flexé: 8 x diamètre total

Ce câble haute performance à 4 paires composé de conducteurs à paire torsadée est principalement utilisé pour la transmission de données. Prise en charge de tous les derniers équipements, il prend en charge une gamme de fréquences allant jusqu'à 250 MHz et des vitesses de transmission allant jusqu'à 1 Gigabit par seconde. Idéal pour les installations où le feu, les émissions de fumée et les vapeurs toxiques présentent un danger potentiel pour la vie et l'équipement.

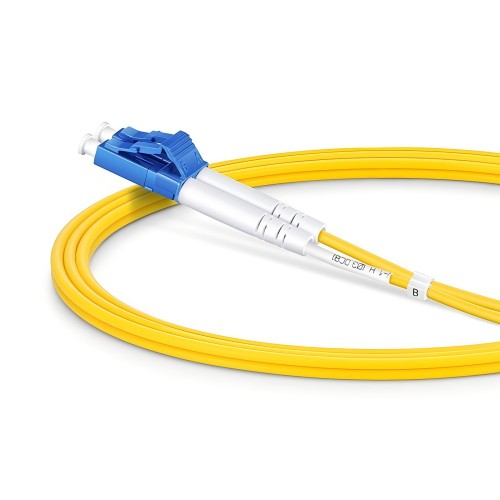

Câble à fibre optique LSZH

STRUCTURE: Mode unique、Fibre、Fil bloquant l'eau、Tube lâche、Fil de verre、CST、Veste LSZH

- Chaque fibre est équipée de marqueurs A/B pour identifier les ports de transmission et de réception afin de garantir une connexion correcte du système.

- Utilisé pour se connecter à des panneaux de brassage et/ou à des équipements réseau à l'aide de connecteurs de type LC qui nécessitent 9/125 câbles LSZH monomodes

- Les connecteurs sont polis PC

- LSZH (Faible fumée, Pas d'halogène) la veste dégage peu de fumées et ne produit aucun gaz halogène toxique

Il est utilisé pour la transmission du signal des systèmes de commande électriques, tels que le contrôle des équipements dans les usines automatisées et les systèmes de contrôle des ascenseurs. Il garantit que les signaux de commande peuvent être transmis efficacement pendant une certaine période de temps en cas d'urgence telle qu'un incendie., afin que l'équipement puisse être arrêté en toute sécurité ou qu'une opération d'urgence puisse être effectuée.

Câbles LSZH isolés PE

Conducteur: Cuivre massif recuit ou cuivre toronné simple

Isolation: Composé PE

Couche d'armure intégrale: Fil d'aluminium/cuivre

Gaine extérieure: LSZH

Tension nominale: 300V

NORMES: DANS 50288-7

Typiquement, ce câble ignifuge LSZH est généralement utilisé pour les installations intérieures, communication, signaux et services de transmission de données et de voix dans les usines de transformation et de fabrication industrielles dans les zones humides, et également pour interconnecter les équipements et instruments électriques afin de réduire les émissions de fumées toxiques.

Normes ignifuges: DANS 60332-1-2; CEI 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1; NBN C 30-004 (chat. F1); NF C32-070-2.1(C2); le 20-35/1-2; DANS 50265-2-1*; DINVDE 0482-265-2-1*

Câble LSZH isolé en caoutchouc de silicone

Conducteur: Conducteur en cuivre toronné ou massif recuit étamé.

Isolation: Caoutchouc de silicone

Tension nominale: 600 volts.

Avantage: Épaisseur de fil uniforme, facile à dénuder et à couper, passe UL VW-1 & Essai de flamme verticale CUL FT1, conducteurs à revêtement de surface disponibles.

Convient aux appareils électroménagers, éclairage, métallurgie et phares, moteurs, capteurs de température, série militaire, séries métallurgiques et chimiques, automobile et maritime, installations électriques.

Normes ignifuges: DANS 60332-1-2; CEI 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1; NBN C 30-004 (chat. F1); NF C32-070-2.1(C2); le 20-35/1-2; DANS 50265-2-1*; DINVDE 0482-265-2-1*

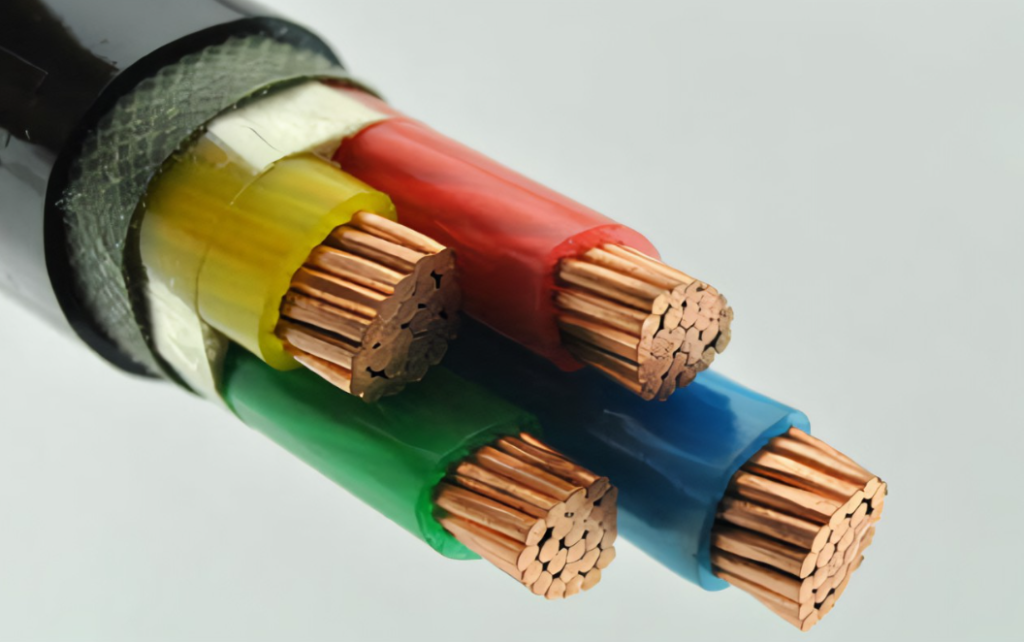

Câble en cuivre ignifuge LSZH XLPE

PVC isolé en polyéthylène à noyau de cuivre WDZN-YJV anneau de gaine de protection câble d'alimentation résistant au feu. Lorsqu'il est posé à l'intérieur, dans les tunnels et les pipelines, le câble ne peut pas résister aux forces mécaniques externes. Les câbles unipolaires ne doivent pas être posés dans des conduites en matériaux magnétiques. Les câbles résistants au feu sont fabriqués selon les normes de l'entreprise. Les performances ignifuges des câbles répondent aux exigences de la norme nationale GB 1266.6, et est divisé en deux catégories différentes de résistance au feu, A et B (950℃~1000℃/90 minutes, 750℃~ 800℃/min). Les câbles ignifuges à faible teneur en fumée et en halogène sont fabriqués selon les normes de l'entreprise. Les performances ignifuges du câble répondent aux exigences de la norme nationale GB1266.5. La transmission de la lumière n'est pas inférieure à 35%, et la libération de chlorure d'hydrogène ne dépasse pas 100 mg/g.

Application | À l'intérieur, tunnels et canalisations |

Taper | Câble d'alimentation |

Certificat | CCC CE CEI |

Conducteur | Cuivre |

Isolation | XPLE+Résistant au feu |

Gaine | LSZH |

Tension | 0.6/1.0kV |

Emballage | Rouler |

Exigences d'isolation des câbles LSZH

Carburant sans halogène à faible émission de fumée

Le degré de résistance à la température de la gaine ignifuge de câble sans halogène à faible fumée est de 70 ℃ et 90 ℃, nécessite généralement un indice d'oxygène du produit supérieur à 32, a de bonnes performances mécaniques et performances de traitement, peut être largement utilisé dans câble d'alimentation, câble de communication, câble de commande, Câble marin et une autre couche de gaine.

Faible fumée Hsans alogène Ccapable Fboiteux R.retardant jeisolant M.matériel

Les propriétés des matériaux isolants ignifuges sans halogène à faible émission de fumée sont similaires à celles des matériaux de revêtement sans halogène à faible émission de fumée., et les exigences de performance d'isolation sont plus élevées. Il peut être utilisé pour la couche isolante du pouvoir, communication, et fils électroniques.

Lpeu de fumée Hsans alogène Fboiteux R.retardant Ccapable Fboiteux R.retardant Ôxygène Bporteur

Le matériau est utilisé pour la couche de gaine intérieure des câbles d'alimentation présentant des exigences élevées en matière de retardateur de flamme., ce qui peut améliorer l'effet ignifuge global du câble et réduire de manière appropriée les exigences ignifuges pour la couche de gaine d'isolation du câble.

À propos du service après-vente de VERI Cable

D'abord, Engagement qualité du produit:

- Il existe des enregistrements de qualité et des données de test pour la fabrication et les tests de tous produits de câble.

- Pour le contrôle des performances des produits, nous invitons sincèrement les utilisateurs à inspecter l'ensemble du processus et les performances du produit en personne. Une fois que le produit est confirmé comme étant qualifié, il sera emballé et expédié.

Deuxième, l'engagement sur le prix du produit:

- Afin de garantir la haute fiabilité du produit, la sélection des matériaux du système est faite de produits nationaux ou de haute qualité.

- Dans les mêmes conditions de concurrence, notre entreprise vous fournira sincèrement à un prix abordable sans réduire les performances techniques du produit ni modifier les composants du produit.

- Engagement de délai de livraison:

Troisième, Délai de livraison du produit:

Dans la mesure du possible selon les besoins des utilisateurs, s'il y a des exigences particulières qui doivent être remplies à l'avance, notre société peut spécialement organiser la production et l'installation, et nous efforçons de répondre aux besoins des utilisateurs.

Quatrième, engagement service après-vente:

- Principe du service: rapide, décisif, précis, réfléchi et minutieux.

- Objectifs du service: la qualité du service pour gagner la satisfaction du client.

- Efficacité des services: Si l'équipement tombe en panne pendant la période de garantie ou en dehors de la période de garantie, après que le fournisseur ait été informé, le personnel de maintenance peut atteindre le site et commencer la maintenance dans les délais 24 heures.

- Principe de service: La période de garantie des produits de câble est de douze mois. Pendant la période de garantie, le fournisseur réparera et remplacera gratuitement les pièces endommagées pour des raisons de qualité. Si les pièces sont endommagées en dehors de la période de garantie, les accessoires fournis ne factureront que le coût des dommages à l'équipement causés par des facteurs humains de l'acheteur, et les accessoires réparés ou fournis par le fournisseur sont calculés au prix coûtant.