Câble d'instrumentation

Les câbles d'instrumentation fabriqués par VERI Cable sont certifiés GB, CEI, BS, ASTM, ISO900, ISO14000, ISO14001, ISO18000, BS, CE, CEI, NFC, ASTM et DIN.

À ce jour, VERI Cable a produit des câbles d'instrumentation destinés à être utilisés dans une variété d'applications et de types, y compris une production entièrement automatisée, équipement électrique, éclairage des tunnels, ou pose dans des tranchées de câbles. La longueur des câbles vendus atteint plus que 50,000 mètres, et leur résistance à l'humidité et à la corrosion est largement appréciée.

Types de câbles d'instrumentation

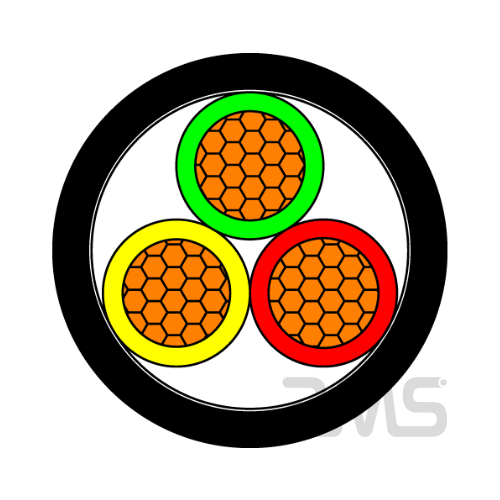

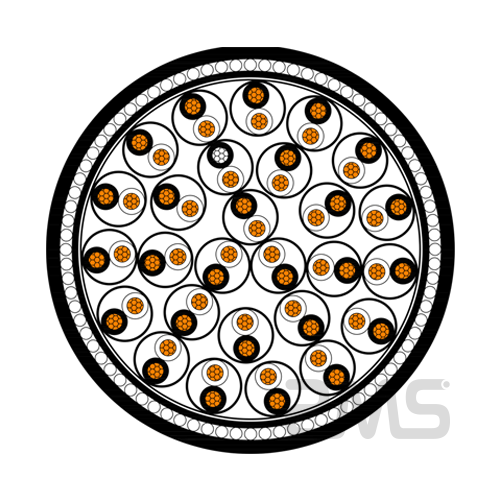

Câble d'instrumentation isolé CU/XLPE --- 0,6/1KV

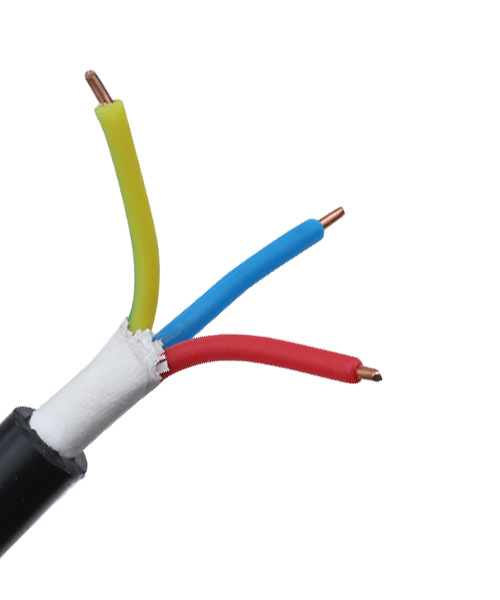

Construction

Conducteur: Cuivre recuit ou étamé

Couplage: Deux ou trois conducteurs isolés uniformément torsadés ensemble avec un pas ne dépassant pas 100 mm

Bande de reliure: Ruban transparent PETP

Standard

CEI 60502, BS 5308, FR 9330

450/750v 0,5 mm2 0,75 mm2 1 mm2 Câble d'instrument isolé CU/XLPE

Blindage | Tresser |

Veste/isolation | PVC/XLPE/PE |

Tension nominale | 600V |

Taille | 0.5mm2-1000mm2 personnalisable |

Taper | Basse tension/moyenne tension/haute tension |

Certificat | OIN, CCC, CE, VDE |

Type de conducteur | flexible |

Gaine | Gaine PVC |

Couleur de la gaine | Noir ou bleu |

Avantages:

Prévention des incendies, anti-impact, anti-rats, anti-moustique, anti-rayonnement

Basse température de travail

Forte résistance aux surcharges

Longue durée de vie, haute sécurité, antidéflagrant, résistance à la corrosion

Haute résistance mécanique

Généralement utilisé dans les usines de fabrication de processus industriels pour les communications, données, et transmission vocale de signaux et de services, et également pour l'interconnexion des équipements et instruments électriques, généralement dans le industrie pétrolière.

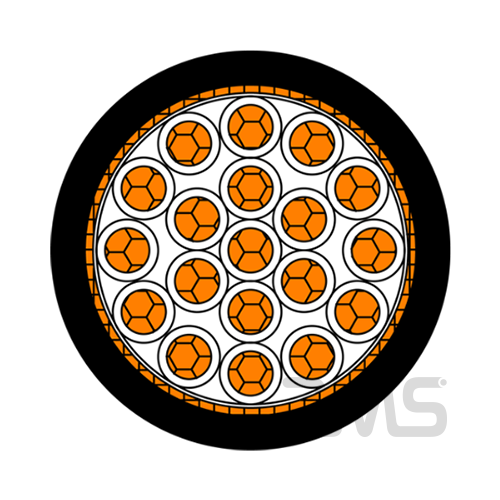

Câble d'instrument à paire torsadée blindé avec ruban de cuivre

2. Tension nominale: Tension nominale maximale. 300V c.a.; Tension nominale AC/D. C110/150V, Tension d'essai Test d'étincelle en cours de processus - tenue à 4 500 V et CA

test de tension – 1500V, DONNÉES TECHNIQUES 0,5 mm 1,5 mm

3. Température de fonctionnement: Température minimale de fonctionnement continu -25°C,75°C, 90°C, Température minimale de court-circuit 160°C (pour 5 seconde)

Matériau conducteur | Alliage d'aluminium de fil de cuivre étamé en aluminium de cuivre/cuivre |

Matériau isolant | PVC/XLPE |

Blindage | Déjouer |

Veste | PVC |

Couleur | toutes sortes de couleurs sont disponibles |

Standard | CEI BS ASTM DIN GB9330-1998 |

Zone de coupe | 0.75 mm2 – 10 mm2 |

blindé | fil d'acier en ruban d'acier |

Gaine intérieure | LSZH (Faible fumée, zéro halogène) Gaine |

Gaine extérieure | LSZH (Faible fumée, zéro halogène) La gaine est ignifuge, conforme à IEC60332-3-22, sans halogène, conforme à IEC60754-1, faibles émissions de fumée, conforme à IEC61034-1-2 |

Tailles de conducteur | 0.5 mm² solide, 1.0 mm² solide, 0.5 mm² souple, 0.75 mm² flexible ou 1,5mm² toronné |

Écran collectif | 24 µm d'aluminium / Ruban PETP sur fil de drainage en cuivre étamé, 0.5 mm² |

Câble électrique à arbre plat pour instruments sous-marins

Ce produit peut être utilisé comme câble de communication sous-marin. Il peut s'agir soit d'une structure de câble réseau unique, soit d'une structure de câble coaxial., un câble réseau et un câble d'alimentation multiconducteur, ou un câble coaxial plus une structure de câble de commande multiconducteur. Le câble réseau est plus que la catégorie 5 ou Catégorie 6, et le câble vidéo est couramment utilisé comme 75-3/75-5, etc.. Ce produit peut également être utilisé comme ligne téléphonique sous-marine. Lors de son utilisation, tu peux choisir 2 paires à utiliser comme lignes d'enregistrement vidéo, et vous pouvez choisir n'importe quelle paire à utiliser comme ligne téléphonique ou comme câble de communication. Il est simple à utiliser et pratique à entretenir.

Conducteur | Fil de cuivre multibrins super fin sans oxygène |

Matériau isolant | matériau imperméable à haute densité |

Blindage | tissu de fil de cuivre étamé |

Veste | polyuréthane résistant à l'eau de mer |

Couleur | les fils centraux se distinguent par différentes couleurs |

Type de câble réseau | CAT5E/CAT6/CA6A |

résistance à la traction | 100/300/500KGpersonnalisé |

Tension nominale | 300/300V |

Écran collectif | 24 µm d'aluminium / Ruban PETP sur fil de drainage en cuivre étamé, 0.5 mm² |

Profondeur de l'eau | 100M/200m/500m, etc. |

Rayon de courbure du treillis métallique en acier à flottabilité nulle:

Installation fixe: 5 × Diamètre extérieur du câble (D)

Installation mobile: Quand l'AVC est<10m, le rayon de courbure est 7.5 × D Lorsque la course est ≥ 10 m, le rayon de courbure est 10 ×D

Conseil de sélection: Sélection de câbles d'instrumentation dans l'industrie pétrochimique

L'industrie pétrochimique, comme l'un des grands domaines industriels, a un environnement de travail difficile impliquant la température, pression, corrosivité et autres conditions extrêmes, ce qui impose des exigences plus élevées en matière de sélection et de conception des câbles d'instrumentation.

Choisissez parmi les câbles d'instrumentation VERI:

— Matériau du câble:

Dans l'industrie pétrochimique, câbles en matériaux résistants à la corrosion, à haute température, Les matériaux ignifuges et ignifuges sont le premier choix. PVC convient aux processus généraux, et polyéthylène PE est le premier choix pour l'huile, acide- et résistant aux alcalins. Les câbles Veri peuvent être personnalisés pour être faits de matériaux à haute température, tel que FEP, PFA, ou caoutchouc en silicone.

- Spécifications et performances du câble:

| Structure du conducteur | Logarithmes | Diamètre extérieur nominal maximum (mm) | Poids nominal (kg/km) |

| 1/0.8mm (0.5mm 2) | 2 5 10 20 30 | 9.7 12.9 17.7 22.9 27.3 | 100 190 320 570 820 |

| 16/0.2mm (0.5mm2) | 2 5 10 20 30 | 11.4 14.6 20.5 26.7 31.7 | 160 250 480 780 1100 |

| 24/0.2mm (0.75mm2) | 2 5 10 20 30 | 12.2 15.7 21.8 28.5 33.7 | 190 270 550 960 1320 |

| 1/1.13mm (1.0mm2) | 2 5 10 20 30 | 12.2 15.6 22.0 29.2 34.8 | 190 270 480 910 1320 |

| 7/0.53mm (1.5mm2) | 2 5 10 20 30 | 13.7 17.8 25.2 33.8 40.4 | 250 400 800 1400 2040 |

Note: En raison de la structure différente des câbles d'instrument, Cette page ne répertorie que les spécifications départementales, tu peux toujours Contactez-nous sur les câbles d'instruments personnalisés.

Conseils d'installation et de câblage du câble d'instrumentation

- —Sous les avant-toits. Les câbles standard ne peuvent être utilisés que s'ils ne sont pas exposés à la lumière directe du soleil ou à une chaleur extrême., et un conduit est recommandé. Ne pas utiliser de câbles sans protection UV en plein soleil.

- —Sur le mur extérieur. Évitez la lumière directe du soleil sur le mur et les dommages causés par l'homme. Les câbles chauffants sont exposés à des températures élevées dans des conduits ou des goulottes métalliques, et de nombreux matériaux polymères connaissent une durée de vie réduite à ces températures.

- —Dans les tuyaux (en plastique ou en métal). Si dans les tuyaux, faites attention aux dommages causés aux tuyaux en plastique et à la conduction thermique des tuyaux métalliques. En cas de dommage mécanique, les câbles à fibres optiques coûtent cher à réparer, exigeant au moins deux terminaisons à chaque point de discontinuité.

- —Demandes suspendues/câbles aériens. Tenez compte de l'affaissement et du stress du câble. Le câble est exposé ou non à la lumière directe du soleil.

- —Pose directe dans la tranchée souterraine du câble, cet environnement est la plus petite plage de contrôle. L'installation de la tranchée de câbles doit être vérifiée régulièrement pour détecter la sécheresse ou l'humidité.. Si le blindage du câble de commande doit être mis à la terre, les normes appropriées doivent être respectées.

Transport VERI avec service professionnel

VERI Cable propose plusieurs façons de protéger vos câbles, avec un emballage d'expédition robuste et professionnel et une assurance tous risques. Avant l'expédition, nos câbles sont conditionnés en bobines de bois et en bobines de carton ondulé. Pendant le transport, pour protéger les extrémités des câbles de l'humidité, nous les scellons avec du ruban adhésif BOPP et non hygroscopique.

S'il y a des problèmes de qualité tels qu'un emballage endommagé et des dommages à la surface du produit sur place lors de la réception des marchandises, si les marchandises sont confirmées comme étant vraies, les marchandises ne correspondent pas à la commande, et les problèmes de qualité rencontrés par le client lors de l'installation, le processus de pose et d'utilisation est confirmé comme étant les problèmes de qualité du produit lui-même, Si la livraison n'est pas conforme aux exigences du contrat, s'il te plaît contactez notre entreprise directement.