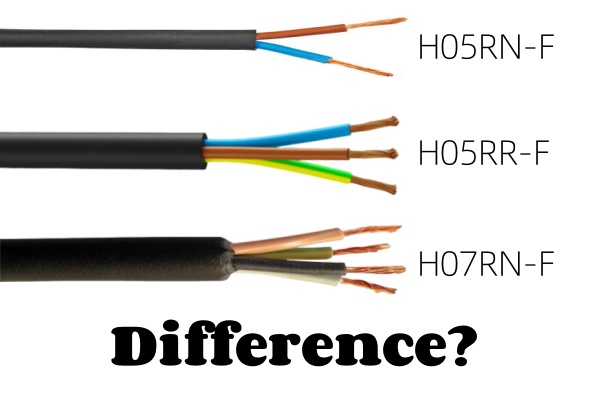

Lors du choix du bon câble en caoutchouc pour un projet de génie électrique, il est essentiel de comprendre les différences entre les différents types. Les modèles de câbles en caoutchouc couramment utilisés incluent H05RR-F, H05RN-F, et h07rn-f, et chacun a ses propres caractéristiques uniques adaptées aux applications spécifiques. Dans cet article, ZMS examinera en profondeur les différences entre ces câbles flexibles, Se concentrer sur leur construction, notes de tension, résistance mécanique et applications typiques. Cliquez pour partager ou favori si vous le souhaitez!

Apprendre UNsur le Types de câbles en caoutchouc flexibles Signification

Les câbles en caoutchouc sont largement utilisés pour leur flexibilité, durabilité et résistance aux facteurs environnementaux, et câbles flexibles sont indispensables pour la transmission de puissance des principaux projets industriels du monde entier à des rénovations de maisons individuelles. Parmi eux, Le H05RR-F, Les noms de modèle H05RN-F et H07RN-F utilisent un système de codage standardisé, Et ce qui suit est des informations sur leurs spécifications:

H:Indique une norme de câble harmonisée.

05 ou 07: Indique la cote de tension. ·

- 05: Classé pour 300/500V.

- 07: Classé pour 450 / 750V.

R.: Signifie une isolation en caoutchouc.

R ou n: Indique le type de matériau de gaine. ·

- R.: Caoutchouc ordinaire.

- N: Chloroprène (néoprène), connu pour améliorer la résistance à l'huile et aux produits chimiques. ·

F: Signifie un câble flexible adapté à la flexion et au mouvement fréquents.

Câble H05RR-F: Câble en caoutchouc léger

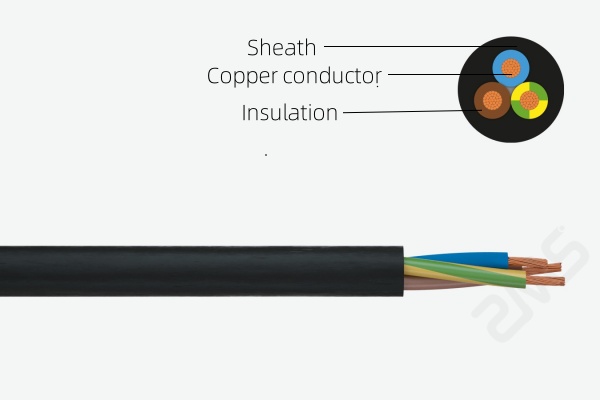

Construction & Caractéristiques

Les câbles H05RR-F sont composés de conducteurs de cuivre à brin fin, isolation en caoutchouc, et une gaine extérieure faite de caoutchouc ordinaire. Ces câbles sont très flexibles et sont conçus pour des applications de service léger.

Tension nominale

Les câbles H05RR-F ont une cote de tension de 300/500V, les rendre idéaux pour les applications à basse tension.

Résistance mécanique & Durabilité

Ces câbles sont conçus pour résister contrainte mécanique légère mais ne conviennent pas aux environnements sévères ou aux applications industrielles robustes.

Applications

Les câbles H05RR-F sont couramment utilisés dans: Appareils de ménage, Outils d'atelier léger, Équipement de poche, Configurations extérieures temporaires (Dans des conditions de stress minimales)

En raison de leur résistance mécanique limitée, Ils ne doivent pas être utilisés dans les applications exposées aux huiles, produits chimiques, ou des conditions environnementales extrêmes.

Câble H05RN-F: Câble en caoutchouc moyen

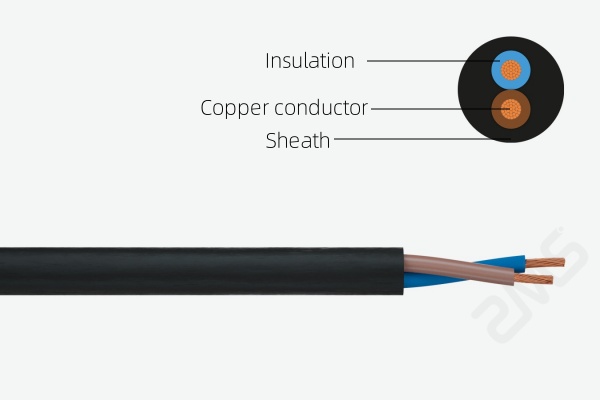

Construction & Caractéristiques

Les câbles H05RN-F sont construits avec isolation en caoutchouc et un gaine en néoprène (chloroprène), ce qui améliore leur résistance à l'huile, produits chimiques, et contraintes mécaniques par rapport aux câbles H05RR-F.

Tension nominale

Les câbles H05RN-F ont également une cote de tension de 300/500V, Similaire à H05RR-F.

Résistance mécanique & Durabilité

Ces câbles sont conçus pour contrainte mécanique moyenne et peut résister aux niveaux de mouvement modérés, flexion, et impacts externes.

Applications

Les câbles H05RN-F sont idéaux pour: Appareils de cuisine, Outils industriels en service moyen, Outils électriques d'atelier, Équipement exposé à l'huile légère et à un contact chimique

Leur gaine en néoprène les rend plus durables que H05RR-F, Permettre une utilisation dans des environnements où une exposition mineure aux huiles et à l'usure mécanique est attendue.

Câble H07RN-F: Câble en caoutchouc lourd

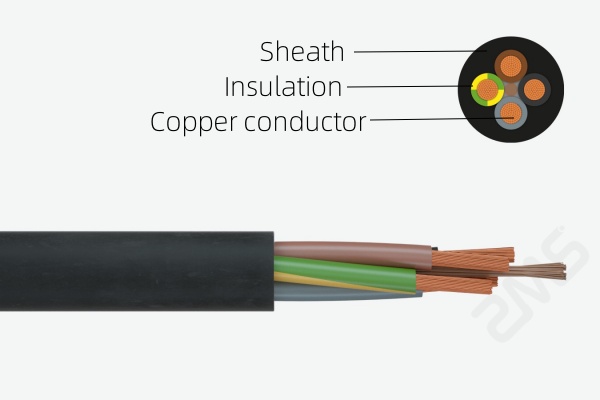

Construction & Caractéristiques

Câbles H07RN-F sont composés de isolation en caoutchouc avec un gaine en néoprène, offrir une résistance supérieure à contrainte mécanique, huiles, produits chimiques, Rayonnement UV, et des conditions météorologiques dures.

Tension nominale

Les câbles H07RN-F sont évalués pour 450/750V, ce qui les rend adaptés aux applications industrielles plus puissantes.

Résistance mécanique & Durabilité

Ces câbles sont conçus pour stress mécanique lourd et peut supporter une manipulation rugueuse, flexion fréquente, et exposition à des conditions extrêmes. Leur nature robuste les rend idéaux pour des environnements exigeants.

Applications

Les câbles H07RN-F sont largement utilisés dans: Machines et équipements industriels, Chantiers de construction, Applications agricoles, Installations extérieures et unités d'alimentation mobile, Applications marines et à bord des navires

Leur durabilité et leur flexibilité en font le choix préféré des environnements nécessitant Résilience mécanique élevée et fiabilité électrique.

H05RR-F H05RN-F H07RN-FDifférences clés résumées

| Fonctionnalité | H05RR-F | H05RN-F | H07RN-F |

| Tension nominale | 300/500V | 300/500V | 450/750V |

| Matériau de la gaine | Caoutchouc ordinaire | Néoprène (Chloroprène) | Néoprène (Chloroprène) |

| Résistance mécanique | Lumière | Moyen | Lourd |

| Huile & Résistance chimique | Faible | Moyen | Haut |

| Aptitude extérieure | Limité | Modéré | Excellent |

| Applications communes | Appareils de ménage, outils légers | Outils d'atelier, appareils de cuisine | Machines industrielles, construction, équipement extérieur |

Comment choisir le bon câble en caoutchouc?

Les utilisateurs doivent prendre en compte les facteurs suivants lors de la sélection du bon câble en caoutchouc:

- Exigences de tension: Assurez-vous que le câble répond aux spécifications de tension de l'application du projet.

- Conditions environnementales: Si le câble est exposé aux huiles, produits chimiques ou environnements extérieurs, Il est préférable de sélectionner un câble gainé en néoprène (H05RN-F ou H07RN-F).

- Contrainte mécanique: Déterminez si le câble sera soumis à la lumière, contrainte mécanique moyenne ou lourde et choisissez en conséquence.

- Conditions de flexibilité: Si l'environnement d'application nécessite une flexion et un mouvement fréquents, Sélectionnez un câble avec une conception très flexible, comme H07RN-F.

Pour d'autres facteurs de sélection incertains, N'hésitez pas à consulter les câbles ZMS.

Comprendre les différences entre H05RR-F, H05RN-F, et h07rn-f câbles flexibles caoutchoutés est essentiel pour sélectionner le bon câble.H05RR-F est le mieux adapté aux applications de légers, H05RN-F offre une durabilité moyenne, et H07RN-F est idéal pour les applications industrielles en service lourd.

Les utilisateurs peuvent garantir des performances optimales et une longévité des installations électriques en tenant compte des différences dans les notes de tension, contrainte mécanique et résistance environnementale de chaque type de câble. Lorsque vous avez besoin de câbles en caoutchouc de haute qualité pour une utilisation industrielle ou commerciale, Assurez-vous de choisir un fournisseur fiable qui répond aux normes de sécurité internationales.