Undersea Power Cable

VERI Cable specializes in submarine power cables for telecommunication and data transmission between various countries or regions. We produce high quality submarine cables in different voltages. In addition to our standard range of marine cables, we also support the design of a number of special submarine cables for specific project applications. VERI produces submarine power cables in accordance with VDE, IEC and ICEA standards or according to customer specifications. For more information about our solutions for submarine cable projects, please feel free to contact us.

Submarine Cable Type and Application

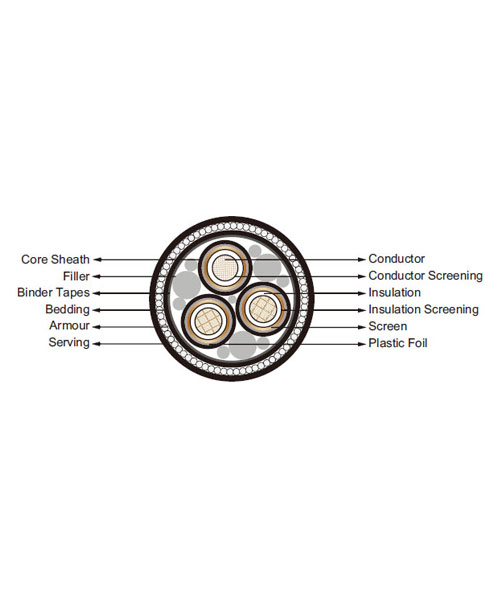

XLPE AC Medium Voltage Submarine Cable

These submarine power cables are used for power transmission to offshore islands, oil platforms, or cross-rivers and lakes. The laying of submarine cables does not require digging tunnels or supporting them with brackets, and low investment or fast construction.

- Conductor: Copper conductor, circular stranded compacted, water blocked

- Conductor Screening: Extruded semi-conductive compound

- ʻO ka hoʻokaʻawale: XLPE

- Insulation Screening: Extruded semi-conductive compound

- Waterproof layer: semi-conductive waterproof tape

- Screen: Copper tapes

- Separator: Plastic foil

- Core Sheath: PE

- Fillers: Polypropylene filler

- Separator: Binder tapes

- Bedding Layer: Polypropylene strings

- Armor: Galvanized steel wires

- Serving: Hessian tapes, bituminous compound, polypropylene strings

Specification Size and Technical Data:

Helu kumu | Nominal Section(mm²) | D.C.Resistance in 20 oC(Ω/km) | O.D.(mm) | Reference Weight(Kg/km) | ||

CU | AL | Cu | Al | |||

1 kumu | 1.5 | 24 | – | 6.1 | 49.2 | 46.6 |

2.5 | 34 | 25 | 6.5 | 61.6 | 61.5 | |

4 | 44 | 33 | 7.4 | 85.4 | 74.3 | |

6 | 57 | 44 | 8.0 | 109 | 90.1 | |

10 | 76 | 58 | 9.6 | 151 | 116 | |

16 | 103 | 78 | 10.2 | 223 | 173 | |

25 | 129 | 108 | 12.0 | 331 | 212 | |

35 | 172 | 131 | 13.1 | 432 | 272 | |

70 | 268 | 207 | 16.0 | 780 | 472 | |

150 | 435 | 335 | 22.1 | 1609 | 821 | |

185 | 493 | 380 | 24.2 | 1966 | 1028 | |

240 | 585 | 451 | 26.9 | 2513 | 1265 | |

2 kumu | 1.5 | 802 | 624 | 33.5 | 4108 |

|

2.5 | 20 |

| 10.2 | 116 | 117 | |

4 | 27 | 21 | 11.0 | 148 | 159 | |

6 | 36 | 27 | 12.8 | 207 | 194 | |

10 | 46 | 35 | 13.8 | 262 | 228 | |

16 | 62 | 48 | 15.4 | 351 | 301 | |

25 | 83 | 63 | 18.5 | 532 | 456 | |

50 | 131 | 101 | 24.3 | 1017 | 573 | |

70 | 164 | 127 | 22.4 | 1201 | 735 | |

95 | 208 | 160 | 25.2 | 1615 | 956 | |

STANDARDS&REFERENCES: IEC 60228, IEC 60502, IEC 60840, IEC 62067

Using Feature:

1. The long-time working temperature of the cable should not be higher than 70℃.

2. When the core is in short-circuit (max 5s) the temperature should not exceed 160℃.

a. For a single no-armored cable, it is not less than 20 times of outer diameter

b. For single-core armored cable, it is not less than 15 times of outer diameter

c. For multicore no-armored cable, it is not less than 15 times of outer diameter

d. For multicore armored cable, it is not less than 12 times of outer diameter

APPLICATION

The core of the underwater power cable is covered with a PE outer sheath. After the single steel armor, the cable is finally completed with an outer sheath. So it is mainly for all marine environmental conditions, such as muddy, dry, wet, or oily conditions meeting the requirements. The range of voltage is 6/10(12)kV,12/20(24)kV, 18/30(36)kV, a laila.

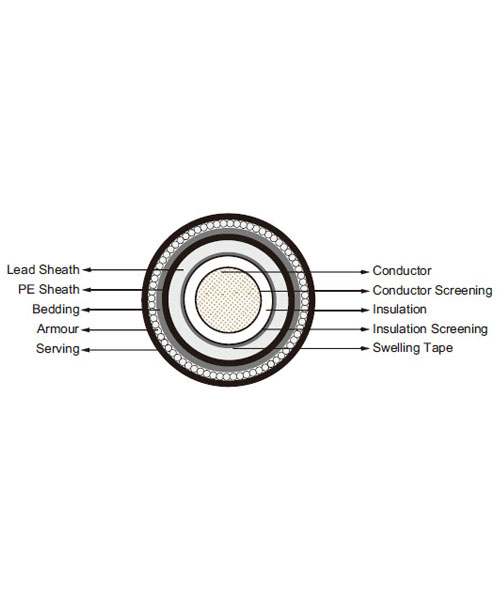

XLPE DC High-Voltage Submarine Cable

DC high-voltage submarine cable is used for high-voltage power transmission. Most of the submarine power cables are on the seabed at a certain depth, and they are not damaging the natural environment, such as wind and waves. Human production activities have interfered with them. No laila, the cables are safe and stable, with strong anti-interference ability and good confidentiality.

- Conductor: Copper conductor, water blocked

- Conductor Screening: Extruded semi-conductive compound

- ʻO ka hoʻokaʻawale: XLPE

- Insulation Screening: Extruded semi-conductive compound.

- Separator: Swelling tape

- Core Sheath1: Lead Sheath

- Core Sheath2: PE sheath

- Bedding: Bedding layer

- Armour: Galvanized steel wires filled with bitumen compound

- Serving: Polypropylene yarn

STANDARDS&REFERENCES:IEC 60228, IEC 60502, IEC 60840, IEC 62067

Nā noi

As a high-voltage transmission cable, it is mainly used to transmit power below the surface of the water and can easily adapt to various treacherous underwater environments. Voltage ranges include 127/220 (245) kV, 160/275 (300) kV, 200/345 (362) kV, 230/400 (420) kV, etc.

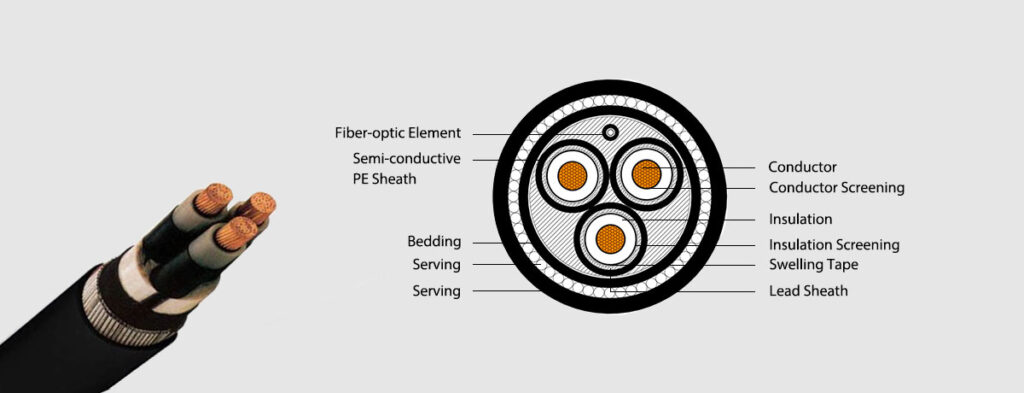

Standards and Applications

STANDARDS: IEC 60502, IEC 62067

APPLICATIONS: This applies to a solidly earthed system with a power frequency of 50-60Hz and rated voltage from 1kV to 500kV. Mainly used for high-power electric power transmission between mainland and island, island and island, or mainland and platform; control signal transmission of smart grid and communication signal transmission.

Our Professional Services

Quality Certification

The products manufactured by VERI Cables comply with international standards such as GB, IEC, BS, NFC, ASTM, DIN, etc. Moreover, our technical team can provide cable customization services for your needs.

Customer Tracking

VERI provides free professional cable consulting services, one-stop project solution services, and fast product delivery solutions.

Professional Transportation

VERI Cables’ initial goal is to ensure fast and safe delivery of products while also providing the best packaging and transportation solutions to reduce customers’ transportation costs greatly.

Cable Packaging

VERI cable packaging is supplied in wooden reels, corrugated boxes, and coils. The ends are sealed with BOPP self-adhesive tape and non-hygroscopic sealing caps to protect the cable ends from moisture. We can print the required logo on the outside of the drums with waterproof material as per the customer’s requirement.