Different Voltage Levels

VERI Cables supplies a wide range of cables with different voltages. Such as low voltage cables, medium voltage cables and high voltage cables. The raw materials include copper or aluminum conductors. Low voltage cables are popular for outdoor or building renovation, but also for instrumentation, raceway and direct burial applications. Sheathing materials are XLPE and PVC, and we have supplied ABC cables, armored cables, airport lighting cables, submarine cables, OPGW cables, and more to projects around the world.

VERI Low-Voltage Cables comprise the core, the insulation, and the protective layer. The core is used to conduct current, generally stranded by multi-stranded copper wire or multi-stranded aluminum wire. Low-voltage cables are single-core, double-core, three-core, four-core, a laila. Dual-core cable for single-phase lines, three-core and four-core cable for three-phase three-wire lines, and three-phase four-wire lines, and single-core cables can be applied to single-phase lines or three-phase lines as needed. Commonly used low-voltage cable core cross-sectional area of 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240 mm, etc.

STANDARDS: IEC 60502, IEC 60332, IEC 61034, IEC 60754, IEC 60986, IEC 60287

APPLICATIONS: Low-voltage cables are a key component of a building’s power supply system and are used for power lines in residential and commercial buildings and public buildings. Includes industrial and manufacturing, marine and offshore engineering.

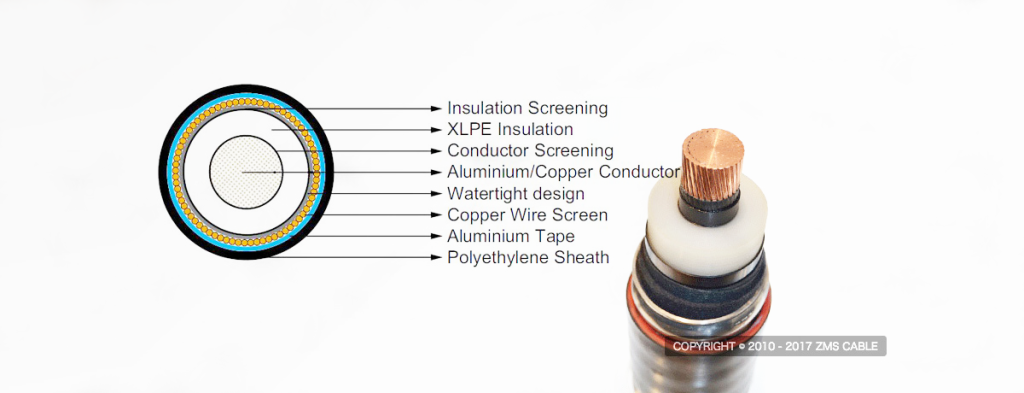

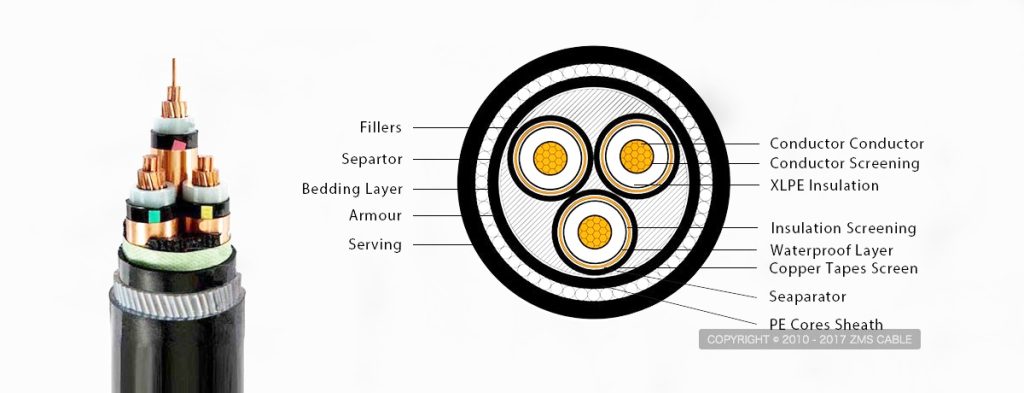

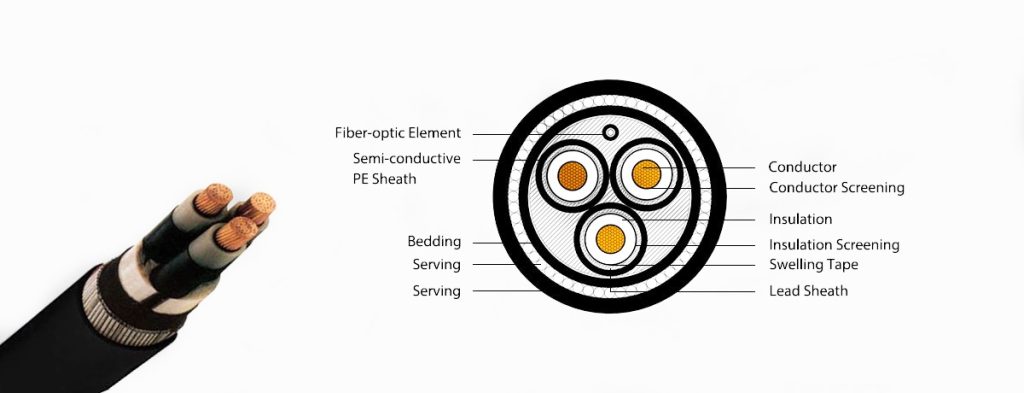

Medium Voltage Cables are power cables with a rated voltage between 6kV and 35kV and are usually used to carry medium voltage power. Medium voltage cables usually consist of one or more copper or aluminum conductors, insulation, sheaths, and other accessories. The conductors of MV cables are usually made of copper or aluminum because these materials have good electrical conductivity and mechanical strength. Insulation is usually made of polyethylene, cross-linked polyethylene, rubber, and other materials to ensure the insulating properties of the cable. The sheath, ma ka lima ʻē aʻe, protects the cable from mechanical damage and environmental influences.

Supply Types:

1. High Quality Medium Voltage Solid Conductor Power Cable

2. Medium Voltage 33kv AAC/AAAC/ACSR Conductor ABC Cable Service Drop Wire

3. MV AL 34.5 KV XLPE INSULATION CONCENTRIC NEUTRAL Power Cable Armoured

The components of a high voltage cable from the inside out include conductor, insulation, inner sheath, filler (armor), and outer insulation. Of course, armored high-voltage cables are mainly used for underground burial, which can resist high-intensity compression on the ground, and at the same time can prevent other external damage. The product is suitable for AC rated voltage 35KV and the following for transmission and distribution of power can be fixed granary line, the maximum long-term working temperature of the cable conductor is 90 degrees, short-circuit (the longest time does not exceed 5S), the maximum temperature of the cable conductor does not exceed 250 degrees.

Supply Types:

1. High Voltage Cable PVC XLPE Cable 100mm 150 mm 15kv

2. Electric Vehicle Wire XLPE Insulated Shielded Tinned Copper Charging EV Cable

3. 18AWG Electrical Black Insulated Copper High Voltage Heating Electric Cable

Standards: IEC 60840, IEC 62067, BS 6622, BS 7835, VDE 0276-620 a pela aku.

About VERI Cable After-Sales Service

First, Product Quality Commitment:

- There are quality records and testing data for the manufacture and testing of all huahana uwea.

- For the inspection of product performance, we sincerely invite users to inspect the whole process and performance of the product in person. After the product is confirmed to be qualified, it will be packaged and shipped.

Ka lua, the product price commitment:

- In order to ensure the high reliability of the product, the material selection of the system is made of domestic or high-quality products.

- Under the same competitive conditions, our company will sincerely provide you at an affordable price without reducing the technical performance of the product or changing the product components.

- Delivery time commitment:

Third, Product delivery time:

As far as possible according to user requirements, if there are special requirements that need to be completed in advance, our company can specially organize production and installation, and strive to meet user needs.

Fourth, after-sales service commitment:

- Service tenet: fast, decisive, accurate, thoughtful and thorough.

- Service objectives: service quality to win customer satisfaction.

- Service efficiency: If the equipment fails within the warranty period or outside the warranty period, after the supplier is notified, the maintenance personnel can reach the site and start maintenance within 24 hola.

- Service principle: The warranty period of cable products is twelve months. During the warranty period, the supplier will repair and replace the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, the provided accessories will only charge the cost the cost of equipment damage caused by human factors of the buyer, and the accessories repaired or provided by the supplier are calculated at cost.