Mining Fiber Optical Cable

As the use of fiber optics in the mining industry is rapidly increasing, in addition to the excellent quality of mining fiber optic cables from Veri cable manufacturers, we sell a wide range of other cables such as submarine cables, overhead cables, coaxial cables, HTLS cables, and other high-quality cables. The success in mining also helps to foster confidence in fibre optic’s applicability to other harsh environment applications. We can also manufacture cables and cables according to customer requirements, so please feel free to contact us if you are in need.

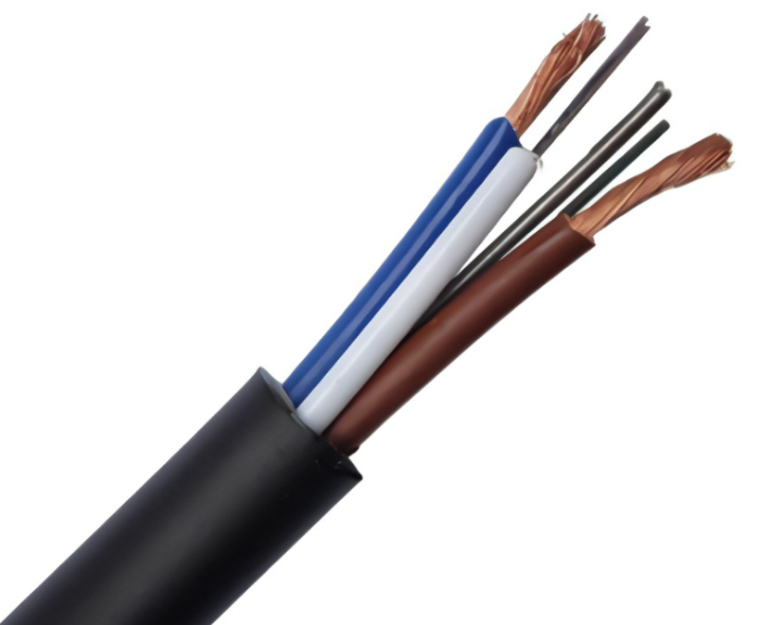

OPLC Photoelectric Composite Fiber Optic Cable

Veri Photoelectric composite cable (OPLC) is to place the protected mining optical cable unit in the power cable, which can be used in power systems with rated voltages of 0.6/1KV and below. It integrates optical fiber, transmission copper wire, and copper signal wire. Broadband access, equipment power consumption, emergency signal transmission, and other issues.

Because of the diversity of access methods and the complexity of the use environment, manufacturers can also customize according to customer requirements, according to different voltages, different fiber cores, and different structures to ensure the safety and reliability of the network.

Features of OPLC Optic Fiber

- It does not require a separate tower because it can install on the same tower as the power lines.

- The construction can carry out without a power outage because the failure of the power line will not affect the normal transmission of the optical cable.

- Non-metallic structure, so good insulation performance, and lightning protection.

- The production process is sophisticated, the aramid yarn is evenly stressed and has excellent stress-strain performance.

- The cable diameter is small, the weight is light, the span can reach 1500M, and the additional load to the tower is low.

- The tensile strength is large, which can exceed 90KN, and the anti-electric corrosion performance is good.

- It has excellent anti-strike performance and can adapt to harsh climatic conditions.

Application of OPLC Optical Cable

- Photoelectric composite cables are generally used in 0.6/1KV low-voltage systems;

- IPTV, Internet access;

- Multimedia phone, voice communication, home smart meter, etc.;

- The connection of the optical communication equipment room, optical distribution rack, instruments, and other equipment.

- The cable is used for communication in coal mines, gold mines, iron ore mines, and other mining applications.

- Duct/Aerial/Direct Buried.

OPGW Photoelectric Composite Optic Cable

The optical fiber is laid on the ground wire of the overhead high-voltage transmission line to form an optical fiber communication network on the transmission line.

This structure has the dual functions of ground wire and communication and is generally called OPGW fiber, because this fiber is resistant to electromagnetic interference, light in weight, and can be installed on the top of the transmission line tower without considering the optimal installation location and electromagnetic corrosion.

Therefore, OPGW has the characteristics of high reliability, superior mechanical properties, and low cost.

This technique is particularly useful and economical when laying or replacing existing ground wires.

Features of OPGW Optical Cable

- It is suitable for high-voltage lines of 110KV and above, easy to maintain, and easy to solve the problem of branching, and its mechanical properties can meet the needs of large-span lines. And OPGW adopts metal armor, which has no effect on high-pressure corrosion and aging. Since the OPGW must be powered off during the construction process, the power loss is large. Therefore, OPGW should be used for new high-voltage lines above 110KV.

- In the performance index of OPGW, the larger the short-circuit current is, the more good conductors need to be used, and the tensile strength also decreases. In the case of a certain tensile strength, the short-circuit current capacity should be increased. Simply increasing the metal cross-sectional area results in an increase in cable diameter and cable weight, creating safety concerns for tower strength.

Application of OPGW Optical Cable

Urban construction

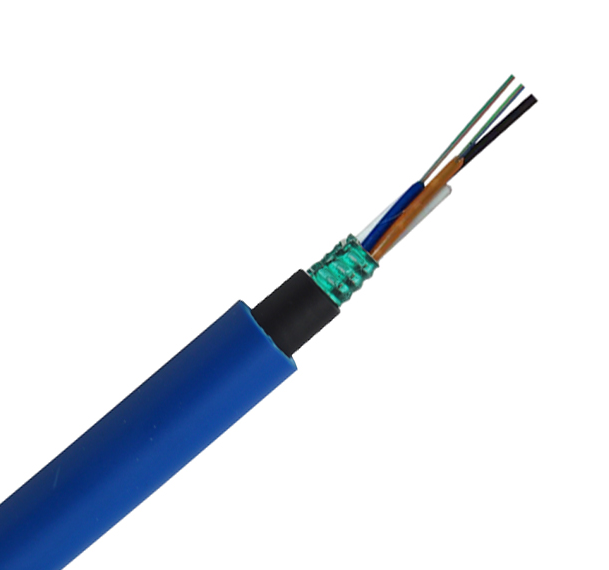

MGTSV Mine Flame Retardant Optical Cable

The structure of MGTSV optical cable is to put 250μm optical fiber into a loose tube made of high modulus material, and the loose tube is filled with a waterproof compound.

The center of the cable core is a metal reinforcing core, around which the loose tube (and filler rope) are twisted into a compact and round cable core, and the gaps in the cable core are filled with water-blocking fillers.

Double-sided plastic-coated steel tape (PSP) is longitudinally wrapped to extrude a polyethylene inner sheath, and a polyethylene outer sheath is extruded outside the inner sheath to form a cable.

Features of MGTSV Optical Cable

- Good mechanical properties and temperature characteristics due to the use of a single wire center reinforcement.

The loose tube is filled with a special waterproof compound, and the loose tube material itself has good water resistance to prevent water seepage from the optical cable. And the inside of the tube is filled with special ointment, which plays a key role in protecting the optical fiber. And it also has good compression resistance and softness. - Use double-sided plastic-coated steel tape (PSP) to improve the moisture-proof permeability of the optical cable, and at the same time, it has the function of an anti-rat. Moreover, the secondary sheath is made of blue flame-retardant PVC, which makes the optical cable have a good flame-retardant effect.

Application of MGTSV Optical Cable

- It is suitable for coal mines, gold mines, iron mines and other mining occasions, as well as tunnel shafts, roadways, and other places with flame retardant requirements.

- It is suitable for long-distance communication and interoffice communication.

About VERI

Veri is a company specializing in the production and processing of optical fiber cables, indoor and outdoor optical cables, power optical cables, special optical cables, optical fiber jumpers, and other products. It has a complete and scientific quality management system.

A high-tech enterprise that manufactures and develops optical communication equipment. The products are widely used in telecommunications, mobile, China Unicom, radio and television, State Grid, military, railway, highway, rail transit, mining, and other communication fields, and have won unanimous praise for the quality and service trusted by users.

The company’s products comply with ITU, IEC, GB/T, YD/T, and international and domestic quality standards in the industry, and effectively run ISO9001 international quality management system certification to ensure product quality is excellent, stable, continuous, and traceable.

The company’s products and technical teams are experts and production craftsmen who have been engaged in the optical fiber cable manufacturing industry for many years and have extensive cooperation with many domestic communication universities to carry out technical exchanges and joint research and development of products. If you have any needs, welcome to consult.