Low Smoke Zero Halogen Cable

The low smoke and halogen free cable supplied by VERI cable has excellent flame retardant properties, almost no smoke and no corrosive gases escaping when burning. They are widely used in nuclear power plants, estasyon metro yo, echanj telefòn ak sant kontwòl òdinatè, bilding ki wo, otèl, estasyon radyo ak televizyon, enstalasyon militè enpòtan yo, oil platforms, and other densely populated places with low air density.

The bending diameter of LSZH cable is not less than 15 times of the outer diameter of the cable, and the bending diameter of single-core cable is not less than 20 times. Others can be customized, free inquiry is welcome.

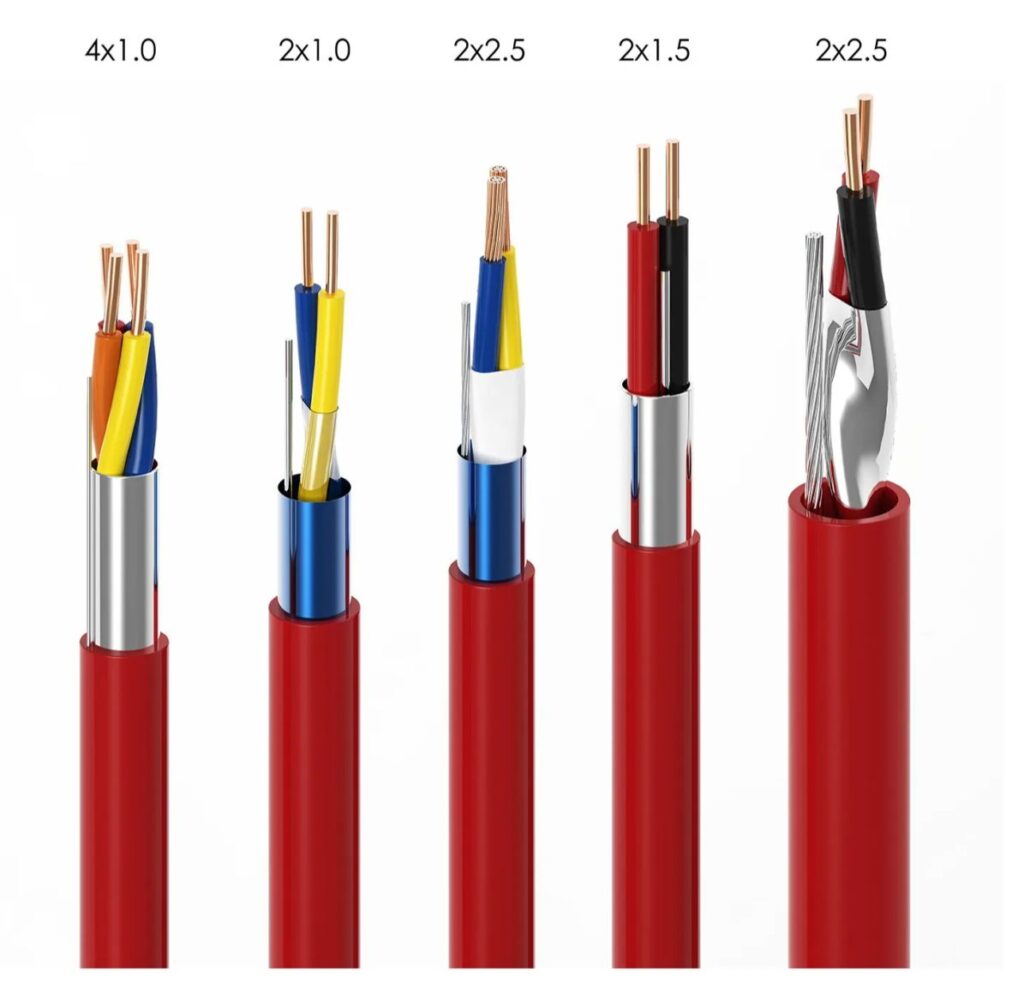

Low Smoke Zero Halogen Cable Types

Control & Communication LSZH Cables: Low smoke and halogen free is a property that cables can have by changing the material. In control cables and communication cables, many cables also incorporate low smoke and halogen free properties in the material to enhance their safety when used in public places.

So LSZH cable has many kinds of parameter specifications, depending on what functions you need it to realize in your project.

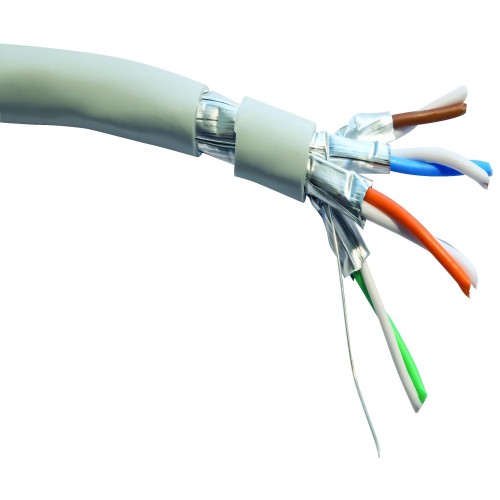

LSZH Cat6 Cable

Kondiktè: Class 1 solid copper conductor

Izolasyon: HDPE (High Density Polyethylene)

Djenn: LSZH (Low Smoke Zero Halogen)

ESTANDA: Flame Retardant according to BS EN/IEC 60332-1-2

CHARACTERISTICS

Temperature Rating: Fixed: -20°C to +60°C

Minimum Bending Radius: Fixed: 4 x overall diameter, Flexed: 8 x overall diameter

This 4-pair high-performance cable consisting of twisted pair conductors is primarily used for data transmission. Supporting all the latest equipment, it supports a frequency range of up to 250 MHz and transmission speeds of up to 1 Gigabit per second. Ideal for installations where fire, smoke emissions and toxic fumes pose a potential danger to life and equipment.

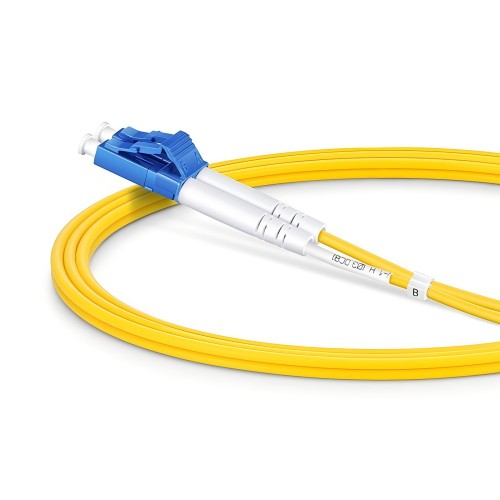

LSZH Fiber Optic Cable

STRUCTURE: Single Mode、Fiber、Water-Blocking Yarn、Loose Tube、Glass Yarn、CST、LSZH Jacket

- Each fiber is equipped with A/B markers to identify the transmit and receive ports to ensure proper system connection

- Used to connect to patch panels and/or network equipment using LC-type connectors that require 9/125 singlemode LSZH cables

- Connectors are PC-polished

- LSZH (Low Smoke, No Halogen) jacket has minimal fumes and produces no toxic halogen gases

It is used for signal transmission of electrical control systems, such as equipment control in automated factories and elevator control systems. It ensures that control signals can be effectively transmitted for a certain period of time in case of an emergency such as fire, so that the equipment can be safely stopped or emergency operation can be carried out.

PE Insulated LSZH Cables

Kondiktè: Annealed solid copper or plain stranded copper

Izolasyon: PE compound

Integral Armor Layer: Aluminum/Copper Wire

Outer Sheath: LSZH

Voltage Rating: 300V

ESTANDA: NAN 50288-7

Typically, this LSZH flame retardant cable is generally used for indoor installations, communication, data and voice transmission signals and services in industrial processing and manufacturing plants in wet areas, and also for interconnecting electrical equipment and instrumentation to reduce the emission of toxic fumes.

Flame Retardance Standards: NAN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; NAN 50265-2-1*; DIN VDE 0482-265-2-1*

Silicone Rubber Insulated LSZH Cable

Kondiktè: Tinned annealed stranded or solid copper conductor.

Izolasyon: Silicone rubber

Rated voltage: 600 volts.

Advantage: Uniform wire thickness, easy to strip and cut, passes UL VW-1 & CUL FT1 vertical flame test, surface coated conductors available.

Suitable for household appliances, lighting, metallurgy and headlamps, motors, temperature sensors, military series, metallurgical and chemical series, automotive and marine, electrical installations.

Flame Retardance Standards: NAN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; NAN 50265-2-1*; DIN VDE 0482-265-2-1*

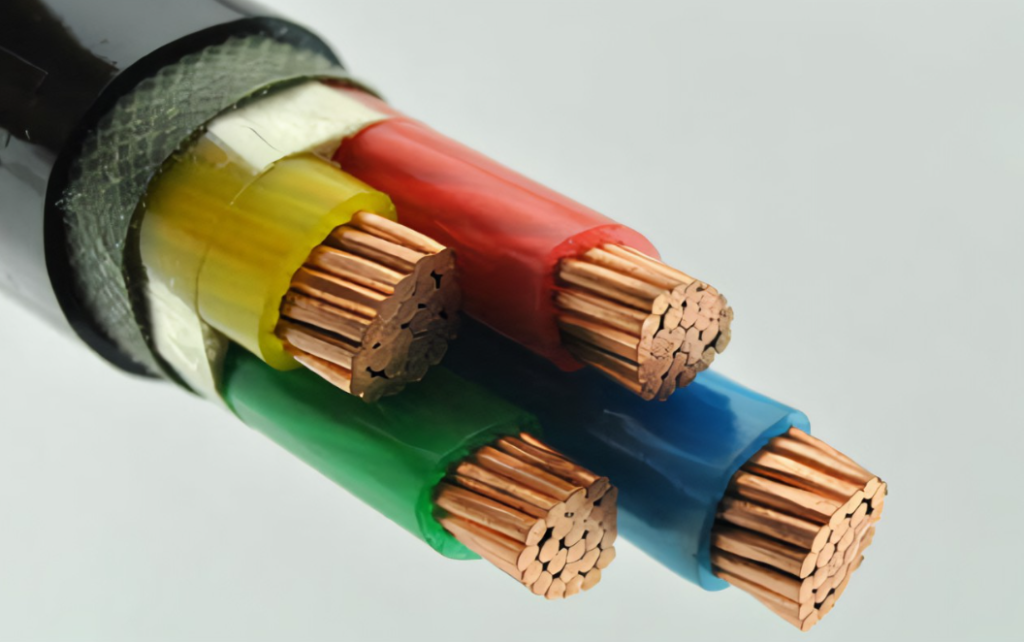

LSZH XLPE Fireproof Copper Cable

WDZN-YJV copper core polyethylene insulated PVC ring protective sheath fire-resistant power cable. When laid indoors, in tunnels and pipelines, the cable cannot withstand mechanical external forces. Single-core cables are not allowed to be laid in magnetic material pipelines. Fire-resistant cables are manufactured according to enterprise standards. The fire-resistant performance of the cables meets the requirements of the national standard GB 1266.6, and is divided into two different fire-resistant categories, A and B (950℃~1000℃/90 min, 750℃~ 800℃/min). Low-smoke and low-halogen flame-retardant cables are manufactured according to corporate standards. The flame-retardant performance of the cable meets the requirements of the national standard GB1266.5. The light transmittance is not less than 35%, and the hydrogen chloride release is not more than 100mg/g.

Aplikasyon | Indoors, tunnels and pipes |

Type | Power Cable |

Certificate | CCC CE IEC |

Kondiktè | Copper |

Izolasyon | XPLE+Fire-resistant |

Djenn | LSZH |

Voltage | 0.6/1.0kV |

Packing | Roll |

Insulation Requirements of LSZH Cables

Low-smoke Halogen-free Fuel

The temperature resistance grade of low-smoke halogen-free cable flame retardant sheath has 70℃ and 90℃, generally requires a product oxygen index of more than 32, has good mechanical performance and processing performance, can be widely used in kab pouvwa, communication cable, control cable, Marine cable and another sheath layer.

Low-smoke Halogen-free Ckapab Flame Retardant mwennsulating Mmateryèl

The properties of low-smoke halogen-free flame-retardant insulating materials are similar to those of low-smoke halogen-free sheathing materials, and the insulation performance requirements are higher. It can be used for the insulating layer of power, communication, and electronic wires.

Low-smoke Halogen-free Flame Retardant Ckapab Flame Retardant Oxygen Barrier

The material is used for the inner sheath layer of power cables with high flame retardant requirements, which can improve the overall flame retardant effect of the cable and appropriately reduce the flame retardant requirements for the cable insulation sheath layer.

About VERI Cable After-Sales Service

Premye, Product Quality Commitment:

- There are quality records and testing data for the manufacture and testing of all cable products.

- For the inspection of product performance, we sincerely invite users to inspect the whole process and performance of the product in person. After the product is confirmed to be qualified, it will be packaged and shipped.

Dezyèmman, the product price commitment:

- In order to ensure the high reliability of the product, the material selection of the system is made of domestic or high-quality products.

- Under the same competitive conditions, our company will sincerely provide you at an affordable price without reducing the technical performance of the product or changing the product components.

- Delivery time commitment:

Third, Product delivery time:

As far as possible according to user requirements, if there are special requirements that need to be completed in advance, our company can specially organize production and installation, and strive to meet user needs.

Fourth, after-sales service commitment:

- Service tenet: fast, decisive, accurate, thoughtful and thorough.

- Service objectives: service quality to win customer satisfaction.

- Service efficiency: If the equipment fails within the warranty period or outside the warranty period, after the supplier is notified, the maintenance personnel can reach the site and start maintenance within 24 èdtan.

- Service principle: The warranty period of cable products is twelve months. During the warranty period, the supplier will repair and replace the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, the provided accessories will only charge the cost the cost of equipment damage caused by human factors of the buyer, and the accessories repaired or provided by the supplier are calculated at cost.