Subsea câbles elektrik

Subsea câbles elektrik yo fil elektrik vlope nan posibilite ak materyèl ki enpèmeyab ak mete anba dlo sou maren an ak nan rivyè pou transmisyon an nan elektrisite oswa kominikasyon. Cables soumaren yo te itilize pou pouvwa van lanmè, Offshore tribin perçage, zile kadriyaj entèrkonèksyon, Land Island entèrkonèksyon ak lòt pwojè lanmè yo bay kominikasyon ak transmisyon pouvwa.

Veri câbles pouvwa soumaren ki te fè rechèch sou pwodiksyon an nan câbles subsea elektrik pou plizyè ane. Si li se soti nan eksplorasyon anviwònman an maren an, Marin sondaj fizik oswa ka etid nan pwojè gwo atravè mond lan. Nou menm tou nou itilize avanse konsepsyon kab, Faktori ak metòd enstalasyon. Câbles elektrik subsea nou yo garanti pou Ekselan rezistans dlo ak lonjevite.

Subsea elektrik pwodwi kab modèl

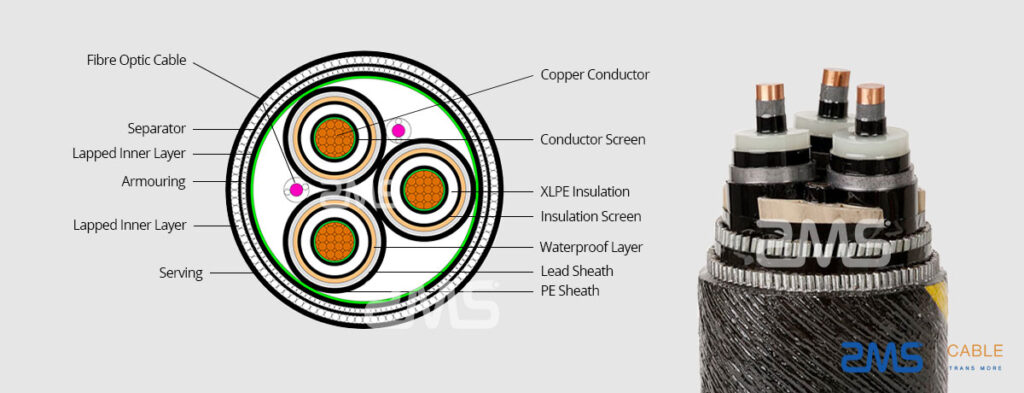

XLPE izole kab soumaren

XLPE izole Subsea pouvwa kab gen plizyè avantaj sou papye-izole ak PVC-izole kab. Li gen gwo fòs elektrik, fòs mekanik, High-aje rezistans, Anviwònman metal estrès reziste kont anti-chimik kwa, Epi li se yon konstriksyon senp, Sèvi ak pratik ak pi wo opere nan tanperati tèm long. Li ka mete ki pa gen okenn restriksyon gout.

Aplikasyon: Sa yo câbles pouvwa subsea yo apwopriye pou enstalasyon fiks nan seri a lanmè, tankou rezo distribisyon oswa enstalasyon endistriyèl. Tankou jeni plant, machin endistriyèl, chofaj ak èkondisyone sistèm yo, estasyon elektrik, elatriye.

Rated vòltaj: | 6/10kV, 6.35/11kV (12kV), 8.7/15kV, 12/20kV, 18/30kV,19/33kV |

Nimewo Nwayo: | Nwayo sèl oswa twa nwayo (1C oswa 3C) |

Dimansyon ki disponib: | 25mm2, 35mm2, 50mm2, 70mm2, 95mm2, 120mm2, 150mm2, 185mm2, 240mm2, 300mm2, 400mm2, 500mm2, 630mm2. |

Modèl | N2xsy, N2xsey, Na2xsy, Na2xKey, N2xsry, Na2xsry, N2xseby, N2xseyby, Nasinseby, N2xsery, Na2xsery, N2xseeyrgby, Na2xseyrgby, YJV, YJLV, Yjsv, Yjlsv |

Kondiktè: | Bloke wonn Compact kwiv oswa kondiktè aliminyòm (Cu / Al ), Fil kwiv rkwit. |

Ekran kondiktè: | Materyèl semi-kondwi |

Izolasyon: | XLPE (Cross-Linked Polyethylene) |

Ekran izolasyon: | Materyèl semi-kondwi |

Ekran metalik: | Ekran kasèt kwiv oswa ekran fil kwiv (Kts / CWS ) |

Baton: | PP kòd |

Separasyon: | Tep obligatwa |

Dra: | PVC (Klori polivinil) |

Armouring: | Single nwayo: Pa gen milti-nwayo: Non |

Djenn: | PVC (Klori polivinil), flanm dife rezistan PVC, PE, Do, HFFR |

Rating tanperati a: | 0° C a 90 ° C |

Siyal blende subsea kab elektrik

Cables elektrik blende yo pwoteje pa zam asye sou deyò nan nwayo a kab, izolasyon an ak andedan djenn ekstèn lan, ak Se poutèt sa gen fò fòs mekanik kont presyon ekstèn ak etann. Epi tou li kapab tou goumen kont korozyon an nan divès kalite sibstans ki sou asid sou maren an, pi fò pwopriyete dlo-bloke. Li gen yon rezistans fò nan tout kalite entèferans nan siyal ak transmisyon pouvwa. Câbles soumaren blende yo nan konstriksyon sa a yo itilize sitou nan min, anba tè, Konstriksyon ak soumaren nan seri a lanmè.

Estanda: IEC 60092-350, IEC 60287, IEC 60332, Pou 606, elatriye.

Aplikasyon pwodwi | Anba tè/min/konstriksyon/soumaren |

Materyèl levit | PUR(TPU)/PVC/kawotchou |

Kondiktè | Bloke kwiv pi bon/konsèv kwiv/tranch plake kwiv |

Izolasyon | PVC/PUR/TEPE/TEPE/RUBY/PE/PE |

Ekran/pwoteksyon | Volontè |

Voltage | Lv/mv/hv |

Koulè djenn | Nwa/wouj/jòn/zoranj/gri/vèt/ble elatriye. |

Dyamèt kab | Dapre demann ou an pou sitasyon pi ba ak bay paramèt teknik |

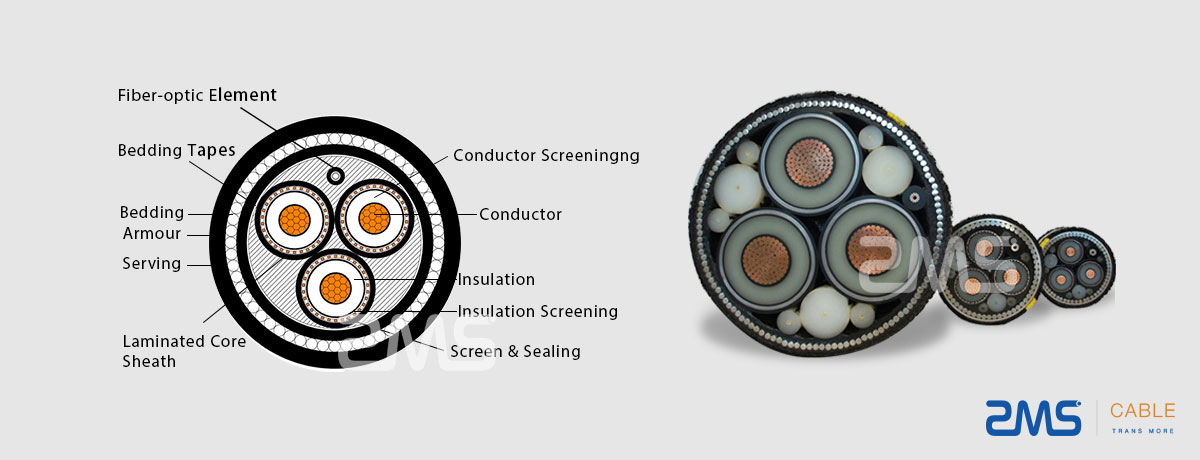

Subsea kab konpoze

Subsea kab konpoze se yon kab transmisyon pi gwo ki pote pouvwa anba sifas dlo a. Li posib tou pou itilize câbles pouvwa soumaren anba dlo a. VERI Kab Èske gen yon seri de ekipman avanse segondè-vòltaj kab ak soumaren kab pwodiksyon ki kapab fabrikasyon teritwa ak câbles pouvwa soumaren nan 500kv ak anba a.

Kalite & Rezon

– Pou fèm van lanmè

– Kab ekspòtasyon transpòte pouvwa a total pwodwi soti nan estasyon an lanmè

– Pou kadriyaj ki konekte nan peyi yo

– Ekipman pou pouvwa soti nan tè pwensipal la nan zile izole

Sistèm vòltaj: | 30kv≤u≤500kv |

Kondiktè: | Sikilè bloke kwiv oswa kondiktè aliminyòm konstwi nan fil wonn oswa définissez. |

Max. CSA 3000sq.mm | |

Izolasyon: | Kwa-lye PE (XLPE) |

Ekran metalik: | 30kv≤u≤66kv: Fil Copper, plon alyaj djenn |

U≥110kv: Plon alyaj djenn | |

Baryè dlo radial: | Konsepsyon semi-sèk: Papye aliminyòm laminated |

Design sèk: Plon alyaj djenn | |

Blende: | Twa-debaz: Fil asye galvanised |

Sèl-nwayo: Fil asye mayetik galvanised; Ki pa Peye-mayetik HD Copper Fil, fil asye pur | |

Kabann zam & sèvi: | Fil polipropilèn |

Nou menm tou nou pwodwi sa yo soumaren kab elektrik la

Nan Soumarin devlopman kab elektrik Se konsa, lwen, Estrikti a te fèt pou fè yon varyete eksplorasyon ak eksperimantasyon, Estrikti prensipal la gen ladan kalite sa yo:

1. Papye ki kouvri ak papye ki kouvri

Apwopriye pou pa plis pase 45kV AC epi yo pa plis pase 400kV liy DC. Kounye a, li se sèlman enstale nan yon pwofondè dlo nan 500 M oswa mwens.

2. Lwil soumaren lwil oliv ki plen

Sèvi ak metòd gwosès siplemantè pou elimine espas lè a nan kab la. Lè tanperati a kab leve, Imp Regnant la ogmante, presyon an andedan kab la ogmante, ak Demon Regnant la koule nan tank la ekipman pou lwil oliv. Lè kab la refwadi, Reklame a ansent, presyon an andedan kab la diminye, ak ansent lan nan tank la ekipman pou lwil koule nan kab la ankò, anpeche jenerasyon twou vid ki genyen lè a. Se konsa, li ka itilize pou 110 KV ak liy ki anwo yo. Tap mete nan fon lanmè jiska 500 m.

3. Enflatab (Presyon-ede) Kab soumaren

Sèvi ak sache papye enpreye nan kab enflatab sou kab lwil oliv-plen se pi apwopriye pou rezo a kab soumaren pi long lan. Men, paske nan bezwen nan opere anba dlo gwo twou san fon lè l sèvi avèk presyon lè segondè, Se konsa, ogmante difikilte pou yo nan konsepsyon kab la ak Pwodwi pou Telefòn li yo, jeneralman limite a yon pwofondè dlo nan 300 m.

4. “Presyon lwil oliv” Tib soumaren kab

Sèlman apwopriye pou plizyè kilomèt nan sistèm kab la, Paske kab la trè long yo rale nan tiyo a, se sijè a gwo kontrent mekanik.

5. Extruded izolasyon XLPE Cables EPR

Apwopriye pou jiska 200kV AC vòltaj. Kawotchou propilèn ethylene se pi plis rezistan a fenomèn dendritik ak flit lokal pase PE, fè câbles soumaren fonksyone pi efikasman.

Kandida nan câbles pouvwa Subsea

Konpleksite nan anviwònman an maren nan pwojè a kab soumaren mete devan kondisyon segondè, Anba dlo kab jeni se yon pwoblèm rekonèt nan mond lan, Difikilte konstriksyon, ak depans antretyen segondè. Epi li te sèlman yon konpayi kèk nan mond lan ka kouche ak komisyon soumaren câbles segondè-vòltaj. Devlopman nan mache a pouvwa subsea te anpil restriksyon. Plis pwoblèm, Men, plis solisyon a pwoblèm nan.

Siyifikasyon nan kab soumaren Veri

Nan lavni, Espas aplikasyon câbles soumaren yo pral pi laj, Li enpòtan ekipman enfrastrikti ak se yon sipò teknik enpòtan pou èt imen yo reyalize ekspansyon an efikas nan zòn aktivite yo. Li transpòte enèji pwòp lanmè nan tè pwensipal la, dispans tansyon nan resous tè pwensipal la, epi tou li transpòte enèji tè pwensipal nan oseyan an, kontribye nan devlopman ekonomi lanmè a. Veri soumaren konpayi kab byen fèm kwè nan sa a.

Câbles customizable soti nan manifaktirè kab Veri

Pwodwi kab soumaren ki te pwodwi pa faktori kab Veri gen ladan câbles pouvwa soumaren, Cables kominikasyon soumarin, soumaren fib fib optik, Câbles anba dlo, Câbles entènèt nan oseyan an, ak lòt pwodwi. Yon varyete de nouvo pwodwi yo te fè rechèch ak endepandamman jije, pran an kont faktè yo konplè nan ekipman yo, materyèl, rekòlt, efikasite konvèsyon, Kalite ak pri, ak bezwen nan metrize distribisyon an dwa pou pwodiksyon. Pou direksyon teknoloji endikap la, Konpayi an te rezève pou pwodiksyon an mas epi li pral lanse pwodwi différenciés selon karakteristik diferan mache yo.

Sèvis pwofesyonèl nou yo

Sètifikasyon Kalite

Pwodwi yo fabrike pa VERI Cables konfòme yo ak estanda entènasyonal tankou GB, IEC, BS, NFC, ASTM, SOTI, elatriye. Anplis, ekip teknik nou an ka bay sèvis personnalisation kab pou bezwen ou yo.

Kliyan Suivi

VERI bay sèvis konsiltasyon kab pwofesyonèl gratis, yon sèl-stop sèvis solisyon pwojè, ak solisyon livrezon pwodwi vit.

Transpò pwofesyonèl

VERI Câbles’ objektif inisyal la se asire livrezon pwodwi rapid ak san danje pandan y ap bay pi bon solisyon anbalaj ak transpò pou diminye kliyan yo’ depans transpò anpil.

Anbalaj kab

Anbalaj VERI kab apwovizyone nan bobin an bwa, bwat corrugated, ak bobin. Pwen yo sele ak tep oto-adezif BOPP ak bouchon sele ki pa igroskopik pou pwoteje pwent kab yo kont imidite.. Nou ka enprime logo obligatwa a sou deyò tanbou yo ak materyèl ki enpèmeyab selon kondisyon kliyan an.