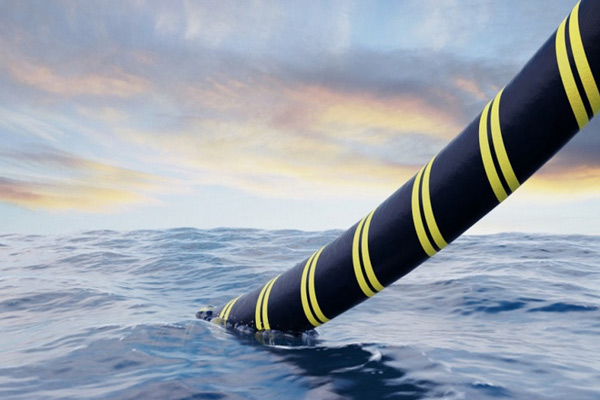

Submarine cables are divided into submarine communication cables and submarine power cables.

Underwater Submarine Armored Cables dominate the international transmission of voice calls and data traffic.

This is mainly because such submarine cables have the advantage of high reliability, security, and capacity offered on major routes as well as cost-effectiveness.

If you are struggling with your submarine cable choices and orders, then you can read this article before deciding to help you make a more precise choice.

Submarine cables are cables wrapped in insulating material and laid on the ocean floor for telecommunication transmission.

Submarine cables are divided into submarine communication cables and submarine power cables.

Modern submarine cables use fiber optics as the material to transmit telephone and internet signals.

The above is a more standard and broad introduction to submarine cables.

But in reality, if you’re choosing submarine cables, you’ll find that there are even more factors that you need to consider.

You even have to understand what submarine composite cables are.

To transmit the electricity generated by offshore wind turbines, a special cable is used.

It combines the functions of a cable and a fiber optic cable and is called a composite submarine cable.

This undersea fiber optic cable is a stranded loose tube cable, surrounded with corrugated steel tape, steel wire armoring, and double sheath.

As the functional unit structure of the cable is relatively fixed, and in principle, not as a bearing unit.

To improve the mechanical strength of the cable it is generally used in the line outside the functional unit to add one or more layers of steel wire armor.

Therefore, the armor’s design becomes the key to the design of the mechanical strength of the cable.

The submarine cable plays the role of both “blood vessel” and “nerve” in the entire wind farm operation structure.

In addition to the collection and transmission of electrical signals. Its internal fiber optic unit is the wind farm communication and cable monitoring signal channel.

Function “two in one” of the sea cable, on the one hand, saves the submarine cable laying channel resources, greatly saving the project cost.

On the other hand, this collection of structures so that the weak armored fiber optic submarine cable has been better protected, and enhanced reliability.

So there are many choices for you about submarine cables.

When selecting submarine optoelectronics composite cables for connection or convergence between turbines and wind turbines. The impact of cable load loss caused by environmental conditions such as penetration of pipes or exposure to sunlight should be considered.

Also, well large length of underwater armored cable distance transmission voltage drops the stability of the system and reactive power increases the system economy.

And because the structural requirements and environmental conditions of submarine cables are different for each wind farm.

In determining the cable cross-section, the wind farm design unit can consult with the submarine cable designers for more reference values of the calculation parameters of the submarine cable.

In fact, before the selection, you will specify the voltage parameters according to your project requirements and sea cable application.

But because the sea cable has two levels of medium voltage and high voltage, even extra high voltage sea cable.

So in some details, you still need to be careful about the choice of submarine cable voltage.

The voltage level of submarine cables can be selected according to the different forms of power grids in various countries and regions.

For example, European countries choose 20kV or 30kV medium-voltage submarine cables to converge wind farm power to onshore or offshore booster stations.

Some Southeast Asian countries mainly use 35kV submarine cables.

Due to the special environment of submarine cable applications. The different voltage levels of submarine photoelectric composite cables need to have different conductive cross-sections. And different mechanical strengths, seawater leakage and corrosion, and other structural characteristics.

And the use of different construction methods to adapt to the intertidal zone, subtidal zone, deep water, stb. To meet the special needs of the offshore wind power industry.

The specific use scenarios and mechanical strength requirements of different types of fiber optic cables shall comply with the following provisions:

1 Light submarine fiber optic cable applied in the deep sea section. Its mechanical strength should meet the requirements of deep-sea surface laying construction maintenance and salvage.

2 Armored submarine fiber optic cable applied in shallow sea section, near-shore section. Its mechanical strength should meet the requirements of buried construction maintenance and salvage.

3 Special protection type submarine fiber optic cables applied in the sea need special protection and should meet the corresponding technical requirements.

All of these are factors that you should consider when purchasing cables.

ZMSCABLE has always been doing a professional job in these counterfactuals. Because there are professional cable sales staff to solve these problems for customers.

Most fiber optic cables are installed through overhead, conduit, és közvetlen temetés.

Underwater fiber optic cables are laid underwater across rivers, lakes, and beaches.

Viszont, when it comes to places like rivers, lakes, and beaches. Laying them with traditional fiber optic cable laying methods will require a lot of fiber optic cable and installation costs.

Underwater armored fiber optic submarine cable perfectly solves the above problems by connecting the two ends through underwater laying.

It saves a lot of fiber optic cables and the laying is simplified.

As fiber optic cables are located under rivers and lakes, they are not affected by wind and most animals on the ground.

Underwater submarine cables offer high transmission capacity, high reliability, high safety, long service life, and low maintenance costs.

Submarine cables have good extrusion resistance.

Its armor layer, although heavy, provides the cable with better tensile strength.

There is also a strong resistance to interference and good confidentiality.

Depending on the application, armored submarine cables can be divided into submarine single armored (SA), submarine double armored (DA), submarine lightweight protected (LWP), submarine lightweight (LW), and submarine lightweight armored (LWA) száloptikai kábelek.

Single-layer armored subsea cable (SA) is a single layer of armored steel wire outside the LW cable, suitable for buried areas within 2000m water depth,

Suitable for deployment, burial, építés, and recovery in areas at a depth of 500 méter, providing the protection required in that depth range.

And should be weighted to prevent tidal waves from moving submarine cables.

Suitable for deployment, építés, and recovery in water depths greater than 1,000 meters and in areas of at least 8,000 méter, but with some resistance to abrasion and fish bites.

Suitable for deployment, építés, and recovery in water depths greater than 1000 meters and at least 8000 méter.

Suitable for deployment, burial, építés, and recovery in areas with water depths of 20 meters and 1500 meters and an unburied depth of 2000 méter.

In the future, with the development of offshore wind energy resources gradually saturated, wind power, rising tariffs down into an inevitable trend. Offshore wind power is bound to move towards distant sea-scale development.

Long-distance, large-scale power output will reduce the power loss on the cable to put forward new needs.

It can be predicted that in the future offshore wind power project, the use of flexible, DC cable delivery will be a trend. All the above sea cable types can be clicked as amicable consulting.

When people hear the term mineral insulated cable, many immediately think of harsh environments like…

As telecommunication networks and power transmission systems grow rapidly, the demand for reliable and cost-effective…

In large-scale oil and gas projects, industrial cables are not just accessories—they are the "nervous…

In the world of electrical connections, cable lugs—also known as cable ears or cable terminals—are…

When choosing the right rubber cable for an electrical engineering project, it is critical to…

Dear partners and customers: January 29th, 2025 is the Chinese Lunar New Year – Spring…