The current underground cables are generally of lower voltage level, and the line transmission with high voltage level is often overhead, which is mainly due to cost and technical factors.

Ultra-high voltage power transmission refers to the use of 500kV-1000kV voltage level to transmit electric energy. If the 220 kV transmission index is 100%, the relative investment per kilometer of ultra-high voltage transmission, the relative cost of 100 kilometers per kilowatt-hour transmission, and the consumption of metal materials will all be greatly reduced, and the utilization rate of the line corridor will be significantly reduced. In daily life, we can often see overhead ultra-high voltage power transmission projects.

Hardly Laying of High-voltage Cables

The structure of underground cables is more complicated than that of overhead lines, the technical requirements are higher, and the manufacturing and construction are difficult. Additionaly, the cables are buried underground, so it is not easy to find faults, and it is also difficult to repair and maintain. In terms of cost, the cost of underground cables of the same voltage level is generally 3 რომ 5 times higher than that of overhead lines.

კერძოდ, our common high-voltage grade lines are often used for long-distance transmission. If underground cables are used, especially long-distance transmission often has to pass through complex terrain, the cost and technical requirements will increase linearly.

On the other hand, overhead lines have good heat dissipation conditions in the air, while the air around underground cables does not flow and it is difficult to dissipate heat, which limits the power level that can be transmitted by underground cables to a large extent. The important thing is that an effective insulating material cannot be found for the outer sheath of the wire for ultra-high voltage transmission. ამიტომ, the ultra-high voltage wires are exposed and cannot be buried in the ground.

Cost of Understand Cables

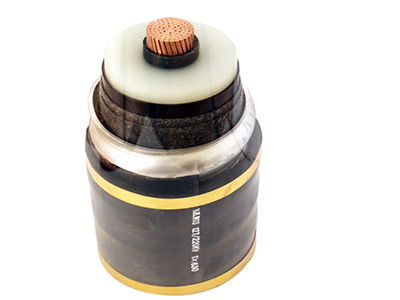

Air is an insulator, but the earth is a conductor. In the air, you only need to put the wires directly there, but in the ground, you need to add layers of insulating casings to the wires, otherwise the electricity in the wires will not go far, and there will be little leakage left. The structure of underground cables is more complicated than that of overhead lines, the technical requirements are higher, and the manufacturing and construction are difficult. Then the cables are buried underground, so it is not easy to find faults, and it is also difficult to repair and maintain. Generally speaking, the cost of underground cables of the same voltage level will be several times or even dozens of times that of high-voltage lines in the air.

Burying ultra-high voltage cables into the ground has both safety and economic problems. If there is a fault, the inspection and repair work of the cables is very huge and cannot stand the toss.

The insulation layer and protective layer of the conductor of the underground cable are very strict, and there is no danger for the human body to touch the outer sheath of the cable normally. The laying of cables is also very particular. Most of the cables are buried in special cable trenches, cable pipes or cable tunnels, which are well isolated and protected. მეტიც, every tens of meters on the ground where the cables are buried, there will be a cable work well or a cable marker pile as a sign to remind people to pay attention to safety. ამიტომ, underground cables generally do not pose a danger to residents.

Dear partners and customers: January 29th, 2025 is the Chinese Lunar New Year – Spring…

Copper wire is a fundamental component in the world of electrical engineering and electronics, valued…

Announcement To all customers and partners, Recently, there has been sufficient evidence that other…

On the occasion of New Year 2025, ZMS Cable wishes every customer and partner a…

The European medical industry has witnessed significant advancements in recent years, driven by the integration…

The successful launch of a rocket involves one of the most complex engineering feats imaginable,…