AAC AAAC ACSR

베리 케이블, 다른 용도에 따라, 다양한 것을 생산합니다 머리 위 케이블. AAC 포함, AAAC, ACSR, ABC 케이블 –공중 번들 케이블, 등. 우리의 오버 헤드 라인의 범위에는 일반적으로 모든 고객의 요구를 충족시키기 위해 알루미늄 도체 또는 알루미늄 합금 도체가 포함되어 있습니다.. 우리는 전송을위한 우수한 오버 헤드 라인을 제공하는 전문입니다, 분포, 전력망 산업. 및 전압 케이블과 같은 기타 케이블 제품, 해저 케이블, 섬유 케이블, 특수 케이블, 등. 따라서 귀하의 요구 사항에 따라 저희에게 연락하십시오. 또한, 우리는 당신이 원하는 자세한 정보를 답장 할 것입니다..

Veri AAC AAAC ACSR의 유형

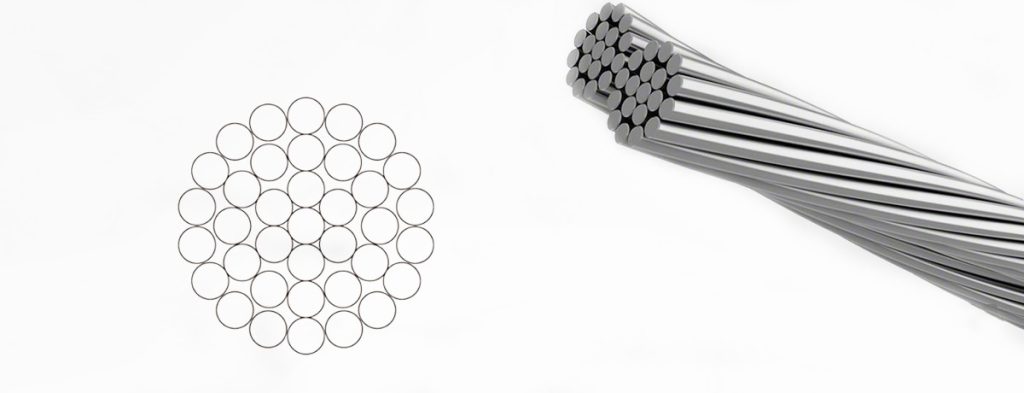

모든 알루미늄 도체 - AAC

알류미늄 합금 지휘자 오버 헤드 전원 라인의 주요 구성 요소입니다. 그 기능은 전류와 전력을 전송하는 것입니다. 이 베어 도체는 낮은 상태에 적합합니다, 중간, 및 고전압 오버 헤드 라인. AAC는 도시 지역에서 널리 사용됩니다, 스팬이 일반적으로 짧은 곳. 그러나 전도도 요구 사항은 높습니다.

표준&참고자료:ASTM —B 230, ASTM —B 231, DIN48201, BS215 (또는 고객 국가의 표준에 따라 생산)

- 단계 도체: 둥근 1350-H19 알루미늄 또는 구리 도체가 둥글거나 압축되었습니다, AAAC, ACSR

- 중립 또는 메신저 도체: 둥근은 서 있거나 압축되었다 6201 알루미늄 합금 또는 AAC, ACSR

- 거리 조명 지휘자: 둥근 알루미늄 도체가 둥글거나 압축되었습니다

- 단열재: LDPE, HDPE, XLPE, PVC

제조 표준

지휘자 크기 | 코드 단어 | 수업 | 필요한 건축 | 대량의 | 정격 강도 | |||||

cmils 또는 awg | mm² | 아니요. 전선의 | 와이어 직경 | 1000ft 당, LB | km 당, kg | 킬로 | kn | |||

~ 안에. | mm | |||||||||

3500000 | 1773 | 블루본 넷 | 에이 | 127 | 0.1660 | 4.22 | 3345 | 4977 | 58.7 | 261 |

3000000 | 1520 | 트릴 리움 | 에이 | 127 | 0.1537 | 3.90 | 2840 | 4226 | 50.3 | 223 |

2750000 | 1393 | Bitterroot | 에이 | 91 | 0.1738 | 4.42 | 2602 | 3872 | 46.1 | 205 |

2500000 | 1267 | 이리 같은 | 에이 | 91 | 0.1657 | 4.21 | 2365 | 3519 | 41.9 | 186 |

2250000 | 1140 | 시나 브러시 | 에이 | 91 | 0.1572 | 3.99 | 2128 | 3166 | 37.7 | 167 |

2000000 | 1013 | Cowslip | 에이 | 91 | 0.1482 | 3.77 | 1873 | 2787 | 34.2 | 153 |

1750000 | 886.7 | 여자 이름 | AA | 61 | 0.1694 | 4.30 | 1641 | 2442 | 29.7 | 132 |

1590000 | 805.7 | Coreopsis | AA | 61 | 0.1614 | 4.10 | 1489 | 2216 | 27.0 | 120 |

1510500 | 765.4 | 글라디올러스 | AA,에이 | 61 | 0.1574 | 4.00 | 1417 | 2108 | 25.6 | 114 |

1431000 | 725.1 | 카네이션 | AA,에이 | 61 | 0.1532 | 3.89 | 1342 | 1997 | 24.3 | 108 |

1351000 | 694.8 | 비둘기 같은 | AA,에이 | 61 | 0.1488 | 3.78 | 1266 | 1884 | 23.4 | 104 |

애플리케이션

모든 알루미늄 도체는 베어 도체에 속합니다, 주로 전기 에너지를 전달하는 역할을합니다. 다른 전압을 기준으로합니다, 와이어 단면 영역도 다릅니다. AAC 케이블은 일반적으로 작은 힘과 작은 스팬을 가진 일반 분배 라인에 사용됩니다.. 그러나 나무와 접촉 할 수 없습니다.

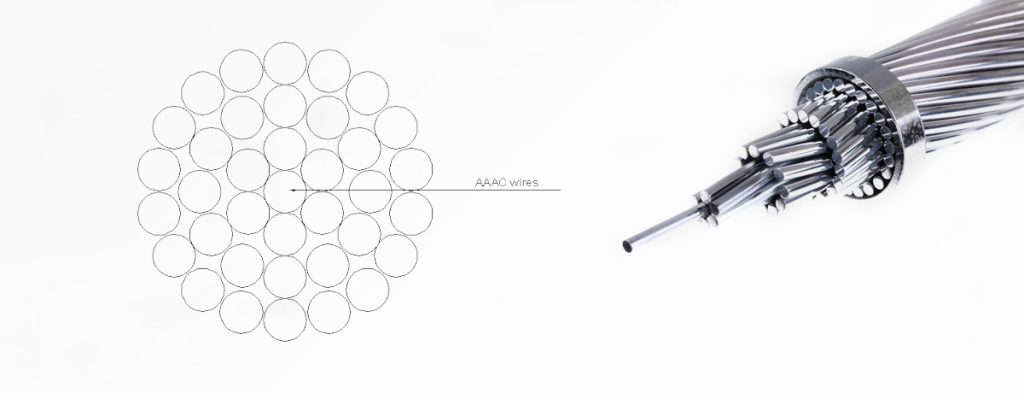

모든 알루미늄 합금 도체 - AAAC

지휘자: 딱딱한 1350-H19 알루미늄 와이어, 최소 순도 99.45%.

보강: 아연 도금 강선 (아연 코팅)

건설 (알루미늄/스틸): 6/1, 7/1, 8/1, 12/7, 16/19, 24/7, 26/7, 30/7, 30/19, 36/1, 45/7, 54/7, 54/19, 72/7, 76/19, 84/19

단면적: 6~ 4/0 awg, 80~ 2312 MCM (80~ 211.3 표준 고 강성 도체의 경우 MCM).

직류 전기 치료: 클래스 A, b 또는 c

기름칠 부식 방지: 요청시 제공됩니다

명세서

AAAC 베어 도체는 다음 ASTM 사양을 충족합니다 :

B-398 전기 목적을위한 알루미늄 합금 6201-T81 와이어

B-399 동심원 가닥 6201-T81 알루미늄 합금 도체.

AAAC-ASTM-B399 기술 데이터의 일부:

좌초 | 도체의 직경 | 선형 질량 | 평가 된 강도 | D.C.. 20 ℃에서 저항 |

아니요 ./mm | mm | kg/km | KGF | Ω/km |

6 | 7/1.55 | 4.65 | 36.44 | 422 |

7/1.68 | 5.04 | 42.7 | 502 | |

4 | 7/1.96 | 5.89 | 57.89 | 685 |

48.69(4) | 7/2.12 | 6.35 | 67.56 | 799 |

2 | 7/2.47 | 7.42 | 92.14 | 1091 |

77.47(2) | 7/2.67 | 8.02 | 107.50 | 1275 |

1/0 | 7/3.12 | 9.35 | 146.50 | 1733 |

123.3(1/0) | 7/3. 37 | 10.11 | 171.00 | 2019 |

2/0 | 7/3.50 | 10.52 | 184.70 | 2090 |

155.4(2/0) | 7/3.78 | 11.35 | 215.16 | 2447 |

3/0 | 7/3.93 | 11.79 | 232.70 | 2641 |

195.7 (3/0) | 7/4.25 | 12.75 | 271.50 | 3079 |

4/0 | 7/4.42 | 13.26 | 293.70 | 3334 |

246.9 (4/0) | 7/4.77 | 14.30 | 342.60 | 3885 |

애플리케이션:

1 차 및 보조 분포를위한 베어 오버 헤드 도체로 사용. AAAC 도체는 더 나은 강도 대량 비율을 얻고 향상된 전기 특성을 제공하도록 설계되었습니다., 우수한 처짐 특성, 및 ACSR과 비교할 때 우수한 부식 저항. 기존의 ACSR 도체와 비교하여, 가벼운 무게, 비슷한 힘 & 현재 운반 능력, 낮은 전기 손실, 그리고 우수한 부식 저항은 AAAC에 분포와 매체에 대한 광범위한 수용을 제공했습니다. & 고전압 변속기 라인.

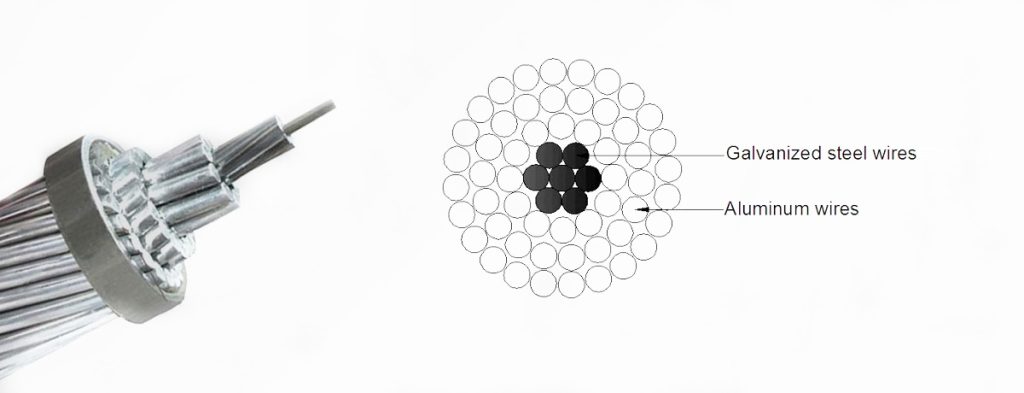

알루미늄 도체 강철 강화 - ACSR

ACSR 도체는 간단한 구조의 장점이 있습니다, 편리한 발기 및 유지 보수, 저선 비용, 그리고 큰 전송 용량. 그리고 그들은 특별한 지리적 조건을 가로 질러 누워서 편리합니다.. 강과 계곡과 같은, 좋은 전기 전도성, 그리고 충분한 기계적.

설계

1 파손 하중이 증가한 알루미늄 도체, 둥근 가닥 압축 (RM)

2 핵심 단열재 (Xple Black, 자외선 방지, 화염 지연이 아닙니다); 2 최대 4 동일한 단면의 코어는 왼쪽에 서로 좌초됩니다., 또한 1 또는 2 감소 된 단면의 코어는 공동 가닥 일 수 있습니다.

표준&참고자료:ASTM —B 230, ASTM —B 231, DIN48201, BS215 (또는 고객 국가의 표준에 따라 생산)

ACSR 기술 특성 / 미국 크기 – ASTM B232

영역 | 가닥 및 직경 | 대략적인 전체 직경 | ||||

알류미늄 | 강철 | 총 | 알류미늄 | 강철 | ||

AWG 또는 MCM | mm2 | mm2 | mm2 | mm | mm | mm |

8 | 8.34 | 1.39 | 9.73 | 6/1.33 | 1/1.33 | 3.99 |

6 | 13.29 | 2.19 | 15.48 | 6/1.68 | 1/1.68 | 5.04 |

4 | 21.16 | 3.55 | 24.71 | 6/2.12 | 1/2.12 | 6.36 |

4 | 21.16 | 5.35 | 26.50 | 7/1.96 | 1/2.61 | 6.53 |

3 | 26.69 | 4.45 | 31.14 | 6/2.38 | 1/2.38 | 7.14 |

2 | 33.61 | 5.61 | 39.22 | 6/2.67 | 1/2.67 | 8.01 |

2 | 33.61 | 8.52 | 42.13 | 7/2.47 | 1/3.30 | 8.24 |

1 | 42.39 | 7.10 | 49.49 | 6/3.00 | 1/3.00 | 9.00 |

0 | 53.48 | 8.90 | 62.38 | 6/3.37 | 1/3.37 | 10.11 |

2/0 | 67.42 | 11.23 | 78.65 | 6/3.78 | 1/3.78 | 11.34 |

3/0 | 85.03 | 14.19 | 99.22 | 6/4.25 | 1/4.25 | 12.75 |

4/0 | 107.23 | 17.87 | 125.10 | 6/4.77 | 1/4.77 | 14.31 |

ACSR의 적용

1. 고강도 ACSR 도체는 다양한 전압 레벨을 갖는 전력 전송 라인에서 널리 사용됩니다..

2. 고층 ACSR 도체는 일반적으로 강 교차로에 사용됩니다., 오버 헤드 접지 와이어, 그리고 긴 스팬과 관련된 설치.

3. 고층 ACSR 도체는 특별한 지리적 특징이 존재하는 강과 계곡을 가로 질러 놓는데도 적합합니다..

VERI 케이블의 우수한 서비스

수출 경험

케이블 전문 제조사로서, 우리의 케이블 제품은 과거에 많은 나라에 수출되었습니다 30 연령, 미국을 포함한, 캐나다, 스페인, 영국, 독일, 프랑스, 러시아 제국, 그리스, 사우디아라비아, 등. 이들 국가에서는, 우리의 케이블 제품은 고객에게 매우 인기가 있습니다. 그리고 매년, 우리의 좋은 품질과 서비스 때문에, 우리는 고객으로부터 많은 좋은 피드백을 받을 것입니다.

맞춤형 케이블 서비스

우리의 다양한 맞춤형 서비스에는 디자인이 포함됩니다., 크기, 그리고 표면색상. 많은 인기 색상도 선택할 수 있습니다.. 우리는 또한 Over Sheathing을 전문으로 합니다., 예를 들어, 우리는 맞춤형 폴리에틸렌을 만들 수 있습니다 (체육) 및 폴리우레탄 (푸르) 귀하의 요구 사항에 따라. 우리는 귀하의 아이디어를 바탕으로 솔루션을 제공할 수 있습니다.. 귀하의 아이디어를 제공하려면 저희에게 연락하십시오.

엄격한 품질검사 기준

Veri Cable은 트렌드와 개인 취향에 따라 다양한 전원 케이블을 제공합니다.. 그리고 우리는 모든 종류의 전원 케이블을 제공합니다, 이상 100 시리즈. 그 다음에, 케이블의 품질을 보장하기 위해, 우리는 때때로 우리 제품을 테스트할 것을 고집합니다..