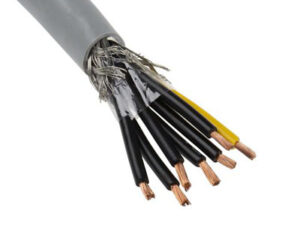

In the vast landscape of electrical engineering, instrumentation cables stand as the unsung heroes, enabling the seamless transmission of signals and data critical for various industrial applications. These cables, often overlooked, play a pivotal role in ensuring the reliability and accuracy of measurement and control systems across a plethora of industries. In this comprehensive guide, we delve into the intricate world of instrumentation cables, exploring their diverse models, applications, and the indispensable role they play in modern engineering.

Instrumentation cables are specially designed to transmit low-energy electrical signals used for monitoring and controlling electrical power systems and their associated processes. Unlike power cables that carry high-voltage currents, instrumentation cables handle low-voltage signals with utmost precision and reliability. These cables are engineered to withstand electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring the integrity of the transmitted signals even in harsh industrial environments.

Twisted pair cables are the most common type of instrumentation cables, consisting of two insulated conductors twisted together. This configuration helps minimize electromagnetic interference, making them ideal for analog and digital signal transmission in various industrial settings. Twisted pair cables come in various configurations, including shielded and unshielded options, providing flexibility to suit specific application requirements.

Multipair cables comprise multiple twisted pairs bundled together within a single sheath. These cables offer the convenience of transmitting multiple signals simultaneously, reducing cable clutter and simplifying installation. Multipair cables are commonly used in complex industrial systems where multiple sensors and control devices need to communicate with a central control unit.

Armored instrumentation cables feature an additional layer of metal armor, providing enhanced mechanical protection against physical damage, such as crushing, impact, and abrasion. These cables are well-suited for harsh industrial environments where the risk of mechanical stress is high, ensuring long-term reliability and durability.

While not as prevalent as copper-based cables, fiber optic instrumentation cables are gaining traction in applications requiring high-speed data transmission over long distances. Fiber optic cables use light signals instead of electrical signals, offering immunity to electromagnetic interference and enabling high bandwidth transmission. They are particularly favored in industries such as telecommunications, мунай жана газ, and aerospace, where data integrity and speed are paramount.

Instrumentation cables form the backbone of industrial automation systems, facilitating the transmission of signals between sensors, actuators, and control systems. These cables are integral to processes such as manufacturing, robotics, and logistics, where precise control and monitoring are essential for optimizing productivity and efficiency.

In the oil and gas sector, instrumentation cables play a crucial role in upstream, midstream, and downstream operations. From remote sensing and monitoring in drilling rigs and pipelines to control systems in refineries and petrochemical plants, instrumentation cables enable safe and efficient operation in challenging environments characterized by extreme temperatures, corrosive substances, and hazardous atmospheres.

Power plants rely on instrumentation cables to monitor and control various parameters, including voltage, current, temperature, and pressure. These cables enable real-time data acquisition and feedback, ensuring the safe and efficient generation, transmission, and distribution of electrical power across the grid.

Instrumentation cables find applications in transportation systems such as railways, Аэропорты, and seaports, where they are used for signaling, traffic control, and surveillance. They also play a vital role in critical infrastructure such as bridges, туннельдер, and dams, providing monitoring and control capabilities for structural integrity and safety.

In the realm of telecommunications, instrumentation cables serve as the backbone of network infrastructure, facilitating the transmission of voice, data, and video signals over long distances. Whether in traditional wired networks or modern fiber optic installations, these cables enable seamless connectivity and reliable communication services for businesses and consumers alike.

Choosing the appropriate instrumentation cable for a specific application requires careful consideration of various factors, анын ичинде:

Evaluate the temperature range, moisture levels, chemical exposure, and other environmental factors to select cables with suitable insulation and sheathing materials capable of withstanding the prevailing conditions.

Consider the type of signals being transmitted, such as analog, digital, or high-frequency signals, and choose cables with the appropriate impedance, capacitance, and shielding properties to minimize signal distortion and interference.

Determine the installation method, whether fixed or flexible, indoor or outdoor, жана select cables with the necessary flexibility, bend radius, and mechanical protection to ensure reliable performance throughout their service life.

Ensure that the chosen instrumentation cables comply with relevant industry standards and regulations, such as IEC, IEEE, NEC, and UL, to guarantee safety, reliability, and interoperability within the intended application.

Instrumentation cables may not always steal the spotlight, but their significance in modern engineering cannot be overstated. From industrial automation and energy production to telecommunications and transportation, these cables form the lifeline of critical systems and processes, enabling seamless communication, башкаруу, and monitoring. By understanding the diverse models, applications, and selection criteria of instrumentation cables, engineers and professionals can harness their full potential to drive innovation, efficiency, and reliability across a wide range of industries.

Минерендердин изоляцияланган кабелди укканда адамдар, many immediately think of harsh environments like…

Телекоммуникация тармактары жана электр берүү тутумдары тез өсөт, the demand for reliable and cost-effective…

Ири масштабдагы мунай жана газ долбоорлорунда, Өнөр жай кабели жөн гана аксессуарлар эмес—they are the "nervous…

Электр байланыштар дүйнөсүндө, кабелдик король—Кабель кулагы же кабелдик терминалдар деп да белгилүү—are…

When choosing the right rubber cable for an electrical engineering project, it is critical to…

Урматтуу өнөктөштөр жана кардарлар: 29-январь, 2025 Кытайдын Ай Жаңы жылы – Spring…