The color of the insulated core of the Contric кабели is generally black and white, and the low voltage of the power cable is generally color-separated. The standard for control cables is 9330, and the standard for power cables is GB12706. And the power cable requires the wire sheath to have sufficient compressive strength, tensile strength, temperature resistance and corrosion resistance. Control cable requirements are relatively low. When the industrial electrical power cables and control cables of the same specification are produced, the insulation and sheath thickness of the power cables are thicker than those of the control cables.

The control cables directly transmit electrical energy from the distribution point of the power system to the power supply connection lines of various electrical equipment and appliances, while power cables are mainly used in power generation, бөлүштүрүү, transmission, transformation. In the transmission of strong electric energy in the power supply line, the current passing through is large, and the power cable is used in the main line of the power system to transmit and distribute large-scale electric energy.

The power cable is a primary load wire, the current carrying capacity increases with the increase of the power. And the application section of the wire must also increase with the current. So the specifications of the power cable are generally larger, as large as 500 чарчы метр (the range that conventional manufacturers can produce). There are relatively few manufacturers who can do it.

And the control cable is a secondary command wire, which controls the current-carrying operation of devices, the load current is extremely small. And the wire cross-section is extremely small. So the cross-section of the control cable is generally small, and the maximum is generally not more than 10 чарчы метр.

The difference between the rated voltage of the power cable and the control cable: the rated voltage of the Кубат кабели is generally 0.6/1kV and above, and the control cable is mainly 450/750V.

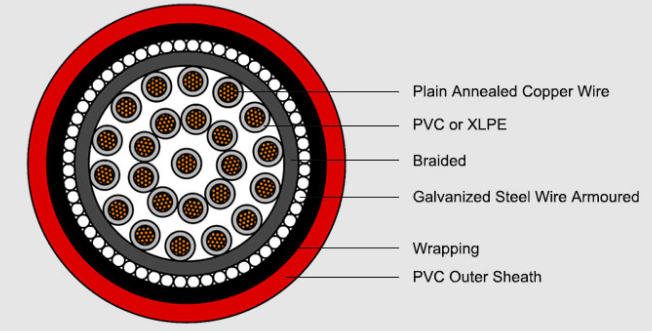

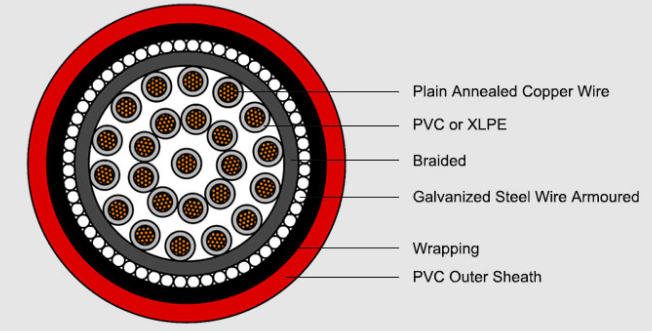

The number of cores of the power cable is less, there are single-core, two-core, 3-core, 4-core (three-phase four-wire system), 5-core (three-phase five-wire system), according to the requirements of the power grid, the maximum is generally 5 өзөктөр. The control cable is used to transmit control signals, and the number of cores is large, ranging from 2 cores to 61 өзөктөр, or even more. The control cable also adopts various core structures, shielding and other measures to obtain satisfactory electromagnetic compatibility effects.

Минерендердин изоляцияланган кабелди укканда адамдар, many immediately think of harsh environments like…

Телекоммуникация тармактары жана электр берүү тутумдары тез өсөт, the demand for reliable and cost-effective…

Ири масштабдагы мунай жана газ долбоорлорунда, Өнөр жай кабели жөн гана аксессуарлар эмес—they are the "nervous…

Электр байланыштар дүйнөсүндө, кабелдик король—Кабель кулагы же кабелдик терминалдар деп да белгилүү—are…

When choosing the right rubber cable for an electrical engineering project, it is critical to…

Урматтуу өнөктөштөр жана кардарлар: 29-январь, 2025 Кытайдын Ай Жаңы жылы – Spring…