In recent years, the most active new products in the cable field should be mineral insulated cables. Many cable manufacturers may also have regular exposure to mineral cables.

Mineral cable is the earliest fireproof cable, originated in Switzerland, and later developed into a specific scale and customized fireproof standard bs6387 standard by the UK. MICC cables generally refer to mineral insulated cables. Meter cables can also be divided into mineral insulated cables and mineral fireproof cables.

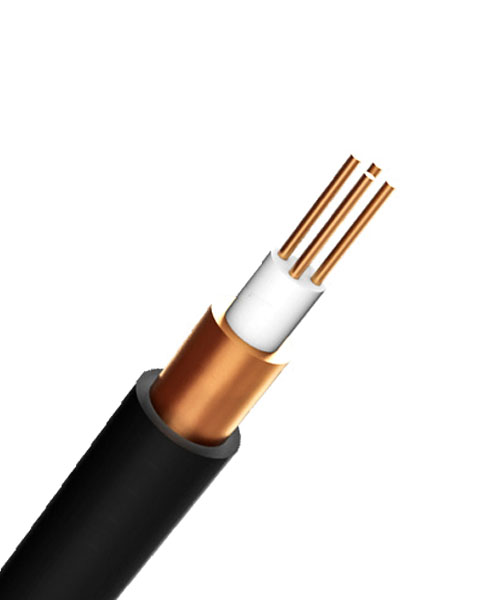

Micc cable is an inorganic material cable. The outer layer of the cable is a seamless copper sheath. Between the jacket and the metal core is a tightly packed magnesium oxide insulating layer. Mineral insulated cables are divided into: wiring cables, heating cables, and compensation cables, Атайын кабель, жана башкалар.

Application of the Мineral Иnsulated Cable

The mineral insulated copper cable itself will not cause a fire and is unlikely to burn. It can continue to supply power when the fire is close to the melting point of copper. It is a real fire-resistant cable. Used in high-rise buildings, petrochemicals, Аэропорты, туннельдер, ships, offshore oil platforms, Aerospace, iron and steel metallurgy, shopping malls, parking lots and other occasions.

Although mineral insulated cables have strong performance, most people think that mic cables are expensive and not used. In recent years, with the continuous efforts of manufacturers and material suppliers, the price of mineral insulated cables has been approaching the cost of ordinary cables.

Cable suppliers also improve the quality of mineral insulated power cables by continuously introducing advanced technology and equipment. Ошол эле учурда, promote this high-quality cable at a more affordable price, and hope that this cable can be more widely used in our lives in the future and contribute to the protection of our lives!

How to Make Mineral Insulated Cables?

The production process and equipment of mineral insulated cables need to be more professional. The following introduces the production process of three kinds of mineral insulated cables.

The first process is also the earliest and most commonly used porcelain column assembly method. At present, most manufacturers of mineral insulated cables use this process. The biggest disadvantage of this cable manufacturing process is the high labor intensity and low production efficiency.

The second process is called the magnesium oxide powder filling method. The standard image analogy is like a funnel between a vertical copper rod and a copper tube filled with magnesium oxide powder. During the filling process, the magnesium oxide powder may become wet. The production workshop is required to be sealed and dry. Air humidity requirements are more stringent.

The third production process is the most advanced copper strip longitudinal welding method in the world. The production process principle of this mineral insulated cable is that the copper strip and the copper rod can be welded infinitely, and the copper strip is longitudinally welded and wound on the copper rod. Magnesium oxide powder is filled between the copper rod and the welded copper strip.