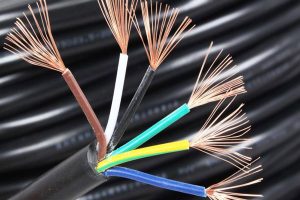

You’re no stranger to cables. Even if you don’t work in the electrical industry, you’ve seen a wide variety of wires and cables on the street and even while charging your cell phone. There are so many types of cables and a wide variety of models, have you ever learned about the six most commonly used electrical cable types in the world today? The following Z cable editorial will take you to understand commonly used electrical cable types, if it is helpful to you then collect it!

Catalog

- Common type power cables

- Control cables

- Frequency conversion cable

- Fire-resistant cable

- Flame retardant cables

Top5: Potentia cables

1 Polyvinyl chloride insulated (PVC) cable

The cable is generally commonly used models of copper-core PVC-insulated power cables (VV), aluminum-core PVC-insulated power cables (VLV), steel belt armored copper-core PVC-insulated power cables (VV22), steel belt armored aluminum-core PVC-insulated power cables (VLV22).

Hi cables’ conductor Slong-term maximum allowable operating temperature of 70 ℃.

PVC cable produces toxic fumes when it burns, so it’s not usually the first choice when people buy cable.

But it is popular for hydraulic hoses, automotive hoses, adhesive tapes, adhesive sheets, PVC profile pipe modification, magnetic materials, and ABS modification.

It remains a leader in cable applications.

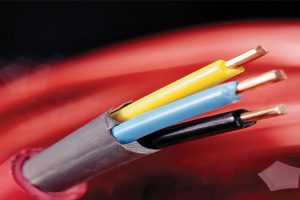

2 Cross-linked polyethylene insulation (Xlpe) cable

The cable is generally used in the type of copper-core cross-linked polyethylene-insulated power cables (YJV), aluminum-core cross-linked polyethylene-insulated power cables (YJLV), steel armored copper-core cross-linked polyethylene-insulated power cables (YJV22), steel armored cross-linked polyethylene-insulated power cables (YJLV22).

The maximum permissible long-term working temperature of the cable conductor is 90℃.

This cable is cost-effective and widely used in various projects.

It is suitable for use in distribution networks, industrial installations, or other areas where large capacity is required.

It is also used for fixed laying on power transmission and distribution lines with AC 50Hz and rated voltage of 6kV to 35kV, and its main function is to transmit power. Not only that, but it is one of the choices for many factories and workshops.

tamen, this power cable has no flame-retardant properties and is more sensitive to ultraviolet rays.

Top4:Control Cable

1 Polyvinyl chloride insulation (PVC) control cable

The common types of this cable are copper core PVC insulated control cable (KVV-450/750V-), and steel belt armored copper core PVC insulated control cable (KVV22-450/750V-).

2 Shielded control cable

Copper core PVC insulated shielded control cable (KVVP-450/750V-), armored copper core PVC insulated shielded control cable (KVVP22-450/750V-).

The cable is especially suitable for places with precision electronic devices. Such as computer centers, automation equipment, instrumentation, robotic equipment, CNC machine tools, aerospace monitoring centers, intelligent buildings, etc.

3 Computer-shielded control cable

The cable is mainly used to lead to automatic control PLC or DCS.

Top3: Frequency conversion cable

1 Frequency conversion power cable

Cross-linked polyethylene insulated shielded main cable for inverter (BPYJVP-), mainly used for inverter circuit.

2 Inverter control cable

PVC insulated shielded control cable for inverter (BPKVVP-450/750V-), mainly used for signal transmission between inverter and power supply.

Top2: Fire-resistant cables

Fire-resistant cables (N or NH-) are generally used in lines that must still maintain normal operation in case of fire. Such as fire-fighting systems, and life-saving systems. And high-temperature environments in industrial and civil buildings.

According to the fire-resistant temperature and duration, fire-resistant cables are divided into Class A, Class B, and Class C.

Top1: Flame retardant cables

Flame-retardant cables (Z or ZR-) should have the ability to stop or delay the occurrence or spread of flame.

According to the temperature and time of the fire supply and other factors, flame retardant cables are divided into A, B, C, and D categories.

Flame retardant cables are very necessary for life applications.

Characteristics of Flame Retardant Cables

Because the flame retardant properties of flame retardant cables are to control the source of fire to continue to burn along the cable, thus reducing the burning area.

And because the flame retardant cable is cheaper, it is the most used cable in fireproof cable and daily life.

Whether it is a cable or multiple cable laying state, the cable can not expand the scope of fire when burned.

Ergo, it can greatly reduce the disaster caused by fire and can enhance the fire strength of the cable.

Flame retardant cables are also used in oil pipelines, oil depots near flammable places, more used in emergency power supply circuits.

Recently, the U.S. Hawaii mountain fire set off a commotion, and the fire has spread to residential areas.

According to U.S. local media reports, Maui County, Hawaii, said in a statement, confirmed by the fire department. The fire is currently raging on the island of Maui and has caused at least 53 deaths. And the local government said the number of casualties may continue to increase.

Insuper, the fires have caused thousands of people to be evacuated and more than 10,000 Maui residents are still facing power outages.

That’s why the use of flame retardant or fire-resistant cables in residential areas and high-rise homes is a very necessary thing.

This is why flame retardant cables, including low smoke halogen-free cables, are listed among the special cables for fire protection in floor dwellings.

These are the most commonly used electrical cable types summarized by ZMS cables, in addition to the commonly used photovoltaic cables.

As more and more businesses and companies are utilizing photovoltaic power due to global climate change and energy conservation nowadays, photovoltaic cables will also be more popular in the future than they are now.

Related Article: