Concentric & Split Cable

Concentric Cables are composed of single-core or multicore conductors, and there is an insulation layer between the multiple conductors, which can effectively prevent electromagnetic interference between the two conductors.

VERI produced Concentric Cables are typical of most cable insulation types. Concentric cables are often used as energy supply cables. Most common in power distribution, panel, and street lighting areas.

Concentric Cable Popular Models

LV Concentric Cable

Dirigent: Copper Class 2

Isolatioun: XLPE / PVC

Kär: Single Core

Cable Inner Sheath: PVC

Concentric Conductor Layer: Kupfer

Cable Tape: No-absorbent material or OEM

Gepanzert: AWA

Cable Outer Sheath: XLPE / PVC / PE / LSZH

Aluminum MV Concentric Cable

Standard: ASTM-B; ASTM-D; UL

Dirigent: 8000 Series Aluminum Alloy

Isolatioun: XLPE / PVC

Kär: Single Core

Cable Inner Sheath: PVC

Concentric Conductor Layer: Aluminum

Cable Tape: No-absorbent material or OEM

Gepanzert: AWA

Cable Outer Sheath: XLPE / PVC / PE / LSZH

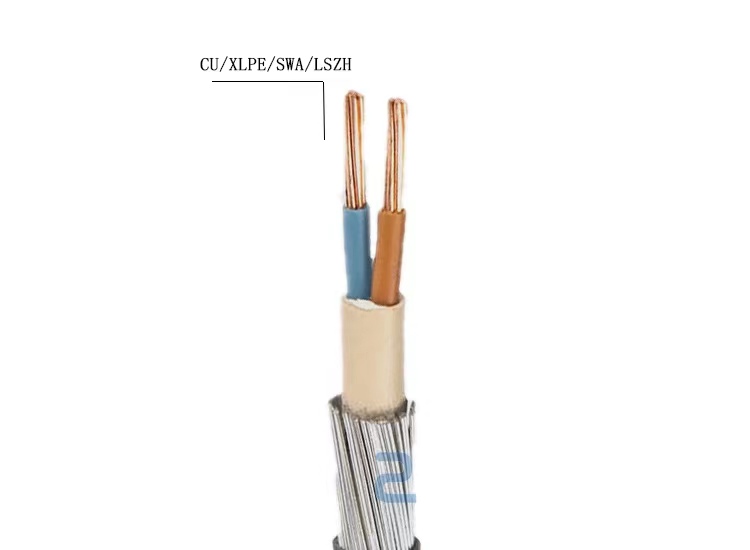

LSZH Split Concentric Cable

Dirigent: Aluminum / Copper Conductor

Isolatioun: XLPE

Kär: Single / Two / Three / Four core

Cable Inner Sheath: PVC

Concentric Conductor Layer: Kupfer / Aluminum

Cable Tape: No-absorbent Material or OEM

Cable Outer Sheath: LSZH

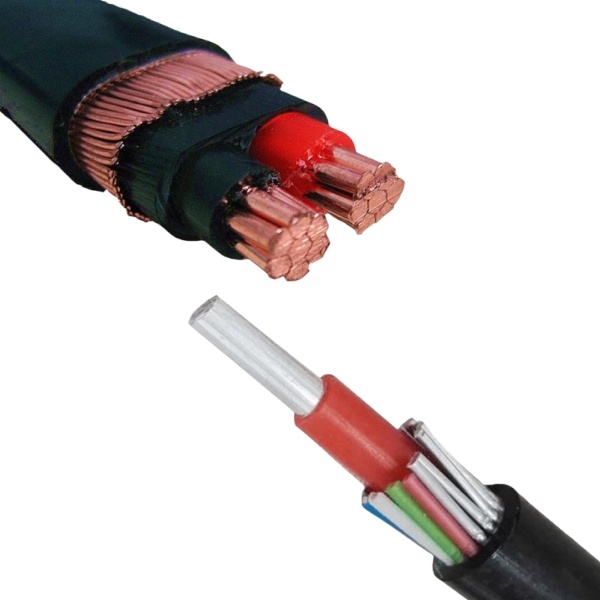

Three/Four Core Concentric Cable

Dirigent: Aluminum / Copper Conductor

Isolatioun: XLPE

Kär: Three / Four core

Cable Inner Sheath: PVC

Concentric Conductor Layer: Copper/Aluminum

Cable Tape: No-absorbent Material or OEM

Cable Outer Sheath: XLPE / PVC / PE

Cable Application

This copper/aluminum conductor concentric cable is used in power distribution lines of rated voltage 600/1000V and below as the connecting cable from the power source to the electricity meter. Concentric conductor cables are suitable for use in dry and wet locations, directly underground or outdoors. The maximum working temperature is 70°C (PVC or PE insulation) or 90°C (XLPE insulation).

Armored concentric conductor cables have better mechanical strength. When buried in the ground, this increases their ability to withstand stresses, reduces damage caused by external forces, and ensures that cables and linked equipment work efficiently.

Cable Specifications

Number of cores: 1, 2, 3, 3+1, 3+2, 4, 4+1, 5 an esou weider.

Typ | Gréisst | Construction | |||||

AWG | Phase Dirigent | XLPE(mm) | Neutral Conductor | UV-PVC(mm) | |||

Nee. | Jo. | Déck | Nee. | Jo. | Déck | ||

Bipolar | 12 | 7 | 0.78 | 1.14 | 39 | 0.321 | 1.14 |

10 | 7 | 0.98 | 1.14 | 25 | 0.511 | 1.14 | |

8 | 7 | 1.23 | 1.14 | 25 | 0.643 | 1.14 | |

6 | 7 | 1.55 | 1.14 | 25 | 0.813 | 1.14 | |

4 | 7 | 1.96 | 1.14 | 27 | 1.02 | 1.14 | |

Tripolar | 8 | 7 | 1.23 | 1.14 | 65 | 0.45 | 1.14 |

6 | 7 | 1.55 | 1.14 | 65 | 0.511 | 1.52 | |

4 | 7 | 1.96 | 1.14 | 65 | 0.643 | 1.52 | |

2 | 7 | 2.47 | 1.14 | 65 | 0.823 | 1.52 | |

Typ | Gréisst | Construction | |||||

mm2 | Phase Dirigent | XLPE(mm) | Neutral Conductor | UV-PVC(mm) | |||

Nee. | Jo. | Déck | Nee. | Jo. | Déck | ||

Bipolar | 10 | 7 | 1.35 | 1.2 | 13 | 0.98 | 1.0 |

6 | 7 | 1.1 | 1.2 | 18 | 0.654 | 1.0 | |

If you don’t know how to choose the products you need or don’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, and we can help you choose the right cable. You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc. We will serve you wholeheartedly. VERI Cable Supplier has a number of quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, VUN, etc.

Excellent Service vum VERI Cable

VERI Kabel huet verschidde Weeër fir Är Kabelen ze schützen, mat robusten a professionelle Versandverpackungen an ëmfaassender Versécherung. Virum Versand, eis Kabelen sinn an hëlzent Rollen a gewellte Këscht coils verpakt. Während dem Transport, fir d'Kabelendunge vu Feuchtigkeit ze schützen, mir Sigel hinnen mat BOPP Self-Kliewefolie an Net-hygroscopic.

Wann et Qualitéitsprobleemer wéi beschiedegt Verpackung a Produktoberflächeschued op der Plaz sinn wann d'Wuer kritt gëtt, wann d'Wuer bestätegt ass wouer ze sinn, d'Wuer passt net un der Bestellung, an d'Qualitéitsproblemer, déi vum Client während der Installatioun fonnt goufen, leeën a Gebrauch Prozess sinn bestätegt d'Qualitéit Problemer vum Produkt selwer, Wann d'Liwwerung net am Aklang mat den Ufuerderunge vum Kontrakt ass, wann ech glift kontaktéiert eis Firma direkt.