Electric Control Cable

VERI Cable has many types of control cables. There are low voltage PVC/XLPE insulation Control Cable, Instrument Cable, Galvanized Steel Wire Armored Control Cables, Flexible Cables, Control Cables with Screen/Shield, 0.6/1kV Paired or Triplex Instrument Cables, 0.6/1kV Paired or Triplex Armored Instrument Cable, etc. As a professional control cable supplier support customizing the different types of control cables to meet all customer needs.

Here at VERI Cable, you can get what you want.

Main Types by Structure

Copper Tape Screened Control Cable

Conductor: Solid or Stranded Copper

Insulation: PVC/PVC(XLPE)

Screen: Copper tape Screen

Sheath: PVC

Rated voltages: 450/750V

Max. Continuous working temp of conductor:70

Upon short circuit (Max. Duration time 5s) the Max.

The temperature of the conductor not higher than160°C;

The ambient temperature of installation not less than 0°C.

Standard: IEC 60227, IEC60228, AS/NZS 5000.2, GB9330

Copper Braid Screen Control Cable

Rated voltage 300/500V. Flexible cable

Standard:BS50525-2-11

Conductor: Stranded Copper or Stranded Tinned Copper class5

Insulation: PVC

Sheathing: PVC

Screen: plain copper wire or tinned copper wire braid

Temperature rating: from 0ºC to +70ºC.

Standard: IEC 60227, IEC60228, AS/NZS 5000.2, GB9330

LV Armored Control Cable

Rated Temperature: 90oC

Rated Voltage: 600/1000V

Reference Standard: GB/T12706, IEC60502

Model: YJV22

Shaped stranded copper conductors

Insulated with cross-link polyethylene compound

PVC bedded

Galvanized steel tape armored

Flame retardant PVC sheathed overall

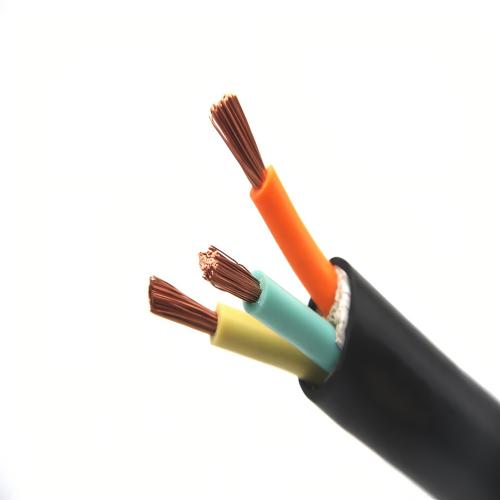

Flexible Electric Control Cable

450/750V PVC insulation single/Multi cores electric wire

This series include the below type:

Copper conductor PVC insulated wires

Copper conductor PVC insulated flexible wires

Copper conductor PVC insulated PVC sheathed flat wires

Copper conductor PVC insulated flat flexible wires

Sizes: 0.5-185mm2

STANDARDS: IEC60227, IEC60502, IEC60332-3, BS6500

Instrument Armored Control Cable

Construction

Conductor: Annealed or tinned copper

Pairing: Two or three insulated conductors uniformly twisted together with a lay not exceeding 100 mm

Binder Tape: PETP transparent tape

Standard

IEC 60502, BS 5308, GB 9330

Control Cable Application Advantages

The control cables we produce are first of all made of the highest quality raw materials in the selection of materials, such as conductors (copper or aluminum) and insulation (XLPE, PVC, PE), etc. Of course, regarding the grade and purity of the raw material material you can contact us for customization.

Under the meticulous processing methods of VERI Cables, all types of control cables are manufactured with better resistance to moisture, corrosion, compression and damage. We assure you of their longevity and after-sales maintenance.

If you have customized needs for control cables, including high temperature resistance, fire retardant properties, etc., please be sure to contact us to discuss.

Veri Cable can offer the proper solution for uncountable applications. Our cable products are widely used in the ranges of the national grid, urban/railway power transportation, substations, solar power plants, etc. With a strong presence in the international market, we export submarine cable, coaxial cable, special cable, fiber optical, and overhead cable to many countries every year.

Our Professional Services

Quality Certification

The products manufactured by VERI Cables comply with international standards such as GB, IEC, BS, NFC, ASTM, DIN, etc. Moreover, our technical team can provide cable customization services for your needs.

Customer Tracking

VERI provides free professional cable consulting services, one-stop project solution services, and fast product delivery solutions.

Professional Transportation

VERI Cables’ initial goal is to ensure fast and safe delivery of products while also providing the best packaging and transportation solutions to reduce customers’ transportation costs greatly.

Cable Packaging

VERI cable packaging is supplied in wooden reels, corrugated boxes, and coils. The ends are sealed with BOPP self-adhesive tape and non-hygroscopic sealing caps to protect the cable ends from moisture. We can print the required logo on the outside of the drums with waterproof material as per the customer’s requirement.