Kejbils termokoppja huma komponenti essenzjali fis-sistemi tal-kejl tat-temperatura industrijali. Dawn il-kejbils jintużaw biex jgħaqqdu t-termokoppji, li tkejjel it-temperatura billi tiġġenera vultaġġ proporzjonali għad-differenza fit-temperatura bejn żewġ junctions tal-metall differenti. L-għażla t-tajba tal-kejbil tat-termokoppja hija kritika biex tiżgura qari preċiż tat-temperatura, jagħmilha vitali li tifhem il-klassifikazzjonijiet u l-applikazzjonijiet tagħha.

Din il-gwida komprensiva tkopri dak kollu li għandek bżonn tkun taf dwar il-kejbils tat-termokoppja, mill-klassifikazzjonijiet tagħhom għad-diversi industriji u applikazzjonijiet li jiddependu fuqhom.

Kejbil termokoppja huwa wajer speċjalizzat użat biex jgħaqqad sensur termokoppja ma 'strument ta' kejl, bħal kontrollur tat-temperatura, meter, jew logger tad-dejta. Il-kejbil iżomm l-integrità tas-sistema termokoppja billi jiżgura li s-sinjal tat-temperatura ma jinbidilx jew jintilef waqt it-trasmissjoni mis-senser għall-istrument.

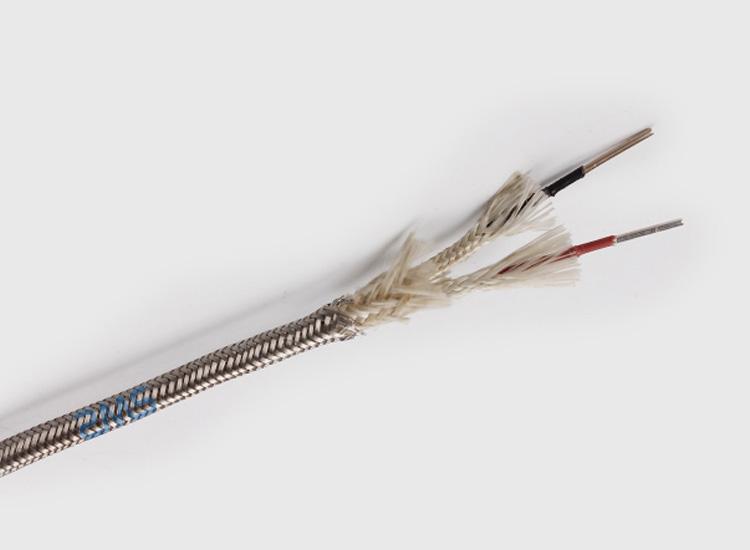

Kejbils termokoppja huma mibnija b'metalli speċifiċi jew ligi għal Qabbel it-tip termokoppja, L-iżgurar li l-karatteristiċi tar-rispons termali jibqgħu eżatti matul il-proċess tal-kejl. Dawn il-kejbils huma wkoll iddisinjati biex jifilħu għal ambjenti industrijali ħarxa, inklużi temperaturi estremi, kimiċi, u xedd mekkaniku.

Kejbil ta 'termokoppja tipiku jikkonsisti minn:

Kejbils termokoppja huma kklassifikati abbażi ta 'diversi fatturi, inklużi tipi ta ’termokoppja, materjali ta 'insulazzjoni, firxa tat-temperatura, u ambjent ta 'applikazzjoni.

Hawn taħt hawn uħud mill-klassifikazzjonijiet ewlenin:

Kejbils termokoppja huma kklassifikati mit-tipi ta 'termokoppja li jappoġġjaw.

L-iktar tipi komuni huma kif ġej:

Tip k (Nickel-Chromium / Nickel-Aluminum): Waħda mit-termokoppji l-aktar użati minħabba l-firxa wiesgħa tat-temperatura tagħha (-200° C sa 1350 ° C.) u affidabilità ġenerali. Adattat għal ambjenti ossidanti.

Tip J. (Ħadid / Constantan): Joffri firxa ta 'temperatura aktar limitata (-40° C sa 750 ° C.) meta mqabbel mat-tip k, Iżda huwa ideali biex jitnaqqsu l-atmosferi.

Tip T. (Ram / Constantan): Topera f'temperaturi baxxi (-250° C sa 400 ° C.) u huwa magħruf għall-eżattezza għolja tiegħu f'applikazzjonijiet krijoġeniċi.

Tip E. (Nickel-Chromium / Constantan): Jipprovdi produzzjoni għolja għal bidliet żgħar fit-temperatura, Utli għal firxa ta 'temperatura ta' -270 ° C sa 1000 ° C.

Tip n (Nickel-Chromium-Silicon / Nickel-Silicon-Magnesium): Termokoppja stabbli għall-użu f'temperaturi għoljin (sa 1300 ° C.), b'reżistenza aħjar għall-ossidazzjoni u drift meta mqabbel mat-tip k.

Tip s, R, u b (Liga tal-Platinum-Rhodium): Dawn it-termokoppji bbażati fuq il-platinu huma adattati għal applikazzjonijiet estremament għoljin, speċjalment f'laboratorji u industriji li jeħtieġu kejl tat-temperatura 'l fuq minn 1450 ° C.

Il-materjal ta 'insulazzjoni huwa kruċjali fid-determinazzjoni ta' fejn jista 'jintuża kejbil termokoppja. Hawn huma tipi komuni ta 'materjali ta' insulazzjoni u l-benefiċċji tagħhom:

PVC (Klorur tal-polivinil): Jipprovdi reżistenza għall-umdità u l-kimiċi. Adattat għal applikazzjonijiet ta 'skopijiet ġenerali u ta' temperatura baxxa sa 105 ° C.

Teflon (Ptfe): Joffri reżistenza eċċellenti għall-kimiċi, umdità, u temperaturi għoljin (sa 260 ° C.). Ideali għal ambjenti ta 'temperatura għolja u korrużiva.

Fibreglass: Reżistenti għal temperaturi għoljin (sa 480 ° C.) iżda inqas effettivi f'ambjenti mgħobbija mill-umdità. Użat komunement fi Settings Industrijali bis-sħana estrema.

Gomma tas-silikon: Magħrufa għall-flessibilità u r-reżistenza tagħha kemm għal temperaturi għoljin kif ukoll għal kimiċi, tagħmilha perfetta għal ambjenti dinamiċi.

Fibra taċ-ċeramika: Jista 'jiflaħ it-temperaturi sa 1200 ° C. Użat f'applikazzjonijiet speċjalizzati ta 'temperatura għolja, speċjalment meta r-reżistenza tal-fjammi hija kritika.

Kejbils termokoppja huma magħżula abbażi tat-tolleranza tat-temperatura tagħhom, li jikkorrispondi għall-materjal tal-konduttur u l-insulazzjoni. Tip k, pereżempju, għandu firxa wiesgħa ta 'temperatura, tagħmilha versatili għal diversi industriji.

F’xi ambjenti, Kejbils termokoppja jistgħu jeħtieġu protezzjoni addizzjonali minn fatturi esterni bħal interferenza elettromanjetika (Emi), ħsara mekkanika, u umdità. Tekniki komuni ta 'lqugħ u armatura jinkludu:

Nisġiet tal-metall jew tarki tal-fojl: Biex tipproteġi kontra interferenza elettromanjetika u żżomm l-integrità tas-sinjal.

Ġkieket tal-Armatura: Saff protettiv robust magħmul minn azzar li ma jissaddadx jew aluminju biex iħares kontra ħsara fiżika.

Kejbils tat-termokoppja jintużaw f’diversi industriji minħabba l-versatilità tagħhom, Durabilità, u eżattezza fil-kejl tat-temperatura. Hawn taħt hawn uħud mill-aktar applikazzjonijiet komuni:

Iż-żamma ta 'kontroll preċiż tat-temperatura hija vitali f'industriji bħall-azzar, siment, ħġieġ, u l-manifattura tal-plastik. Termokoppji u l-kejbils li jakkumpanjawhom jimmonitorjaw u jirregolaw proċessi ta 'temperatura għolja, L-iżgurar tal-kontroll tal-kwalità u s-sigurtà fil-produzzjoni.

Fis-settur taż-żejt u tal-gass, Kejbils termokoppja huma skjerati f'ambjenti ħorox, bħal pjattaformi offshore, raffineriji, u pjanti petrokimiċi. Jintużaw biex jimmonitorjaw it-temperatura tal-linji tal-pajpijiet, Tagħmir tat-tħaffir, u sistemi oħra li joperaw f'kundizzjonijiet estremi.

Kejbils termokoppja jintużaw b'mod estensiv fil-pjanti tal-ġenerazzjoni tal-enerġija, speċjalment fit-turbini, bojlers, u r-reatturi, fejn il-ġestjoni tat-temperatura hija essenzjali għall-effiċjenza u s-sigurtà.

L-industrija aerospazjali titlob kejl tat-temperatura preċiż u affidabbli waqt kundizzjonijiet estremi waqt l-operazzjonijiet tal-manifattura u tat-titjira.

Thermocouples spiss jintużaw fi:

Kejbils termokoppja huma komunement użati fl-HVAC (Tisħin, Ventilazzjoni, u arja kondizzjonata) Sistemi biex jimmonitorjaw it-temperatura u jiżguraw l-effiċjenza fl-enerġija. Huma utilizzati fit-termostati, Pompi tas-sħana, u sistemi ta 'refriġerazzjoni għal kontroll preċiż tat-temperatura.

Iż-żamma ta 'temperatura xierqa fl-industrija tal-ikel hija essenzjali għas-sigurtà u l-kontroll tal-kwalità. Kejbils termokoppja jintużaw biex jimmonitorjaw it-tisjir, Tkessiħ, u temperaturi tal-ħażna, L-iżgurar tal-konformità mar-regolamenti tas-saħħa u s-sigurtà.

F'applikazzjonijiet mediċi, It-termokoppji huma essenzjali għall-monitoraġġ tat-temperaturi tal-ġisem tal-pazjent waqt proċeduri kirurġiċi u f'ambjenti ta 'kura kritika. Jintużaw ukoll fi proċessi ta 'sterilizzazzjoni għal tagħmir mediku, L-iżgurar ta 'riżultati sikuri u effettivi.

Kejbils termokoppja joffru diversi benefiċċji, jagħmluhom indispensabbli fis-sistemi tal-kejl tat-temperatura:

Meta tagħżel il-kejbil termokoppja dritt għall-applikazzjoni tiegħek, Ikkunsidra l-fatturi li ġejjin:

Kejbils tat-termokoppja għandhom rwol vitali fl-iżgurar tal-eżattezza u l-affidabbiltà tas-sistemi tal-kejl tat-temperatura f'diversi industriji. Nifhmu l-klassifikazzjonijiet tagħhom, applikazzjonijiet, u l-benefiċċji jistgħu jgħinuk Agħżel il-kejbil it-tajjeb għall-bżonnijiet speċifiċi tiegħek, L-iżgurar ta 'prestazzjoni ottimali anke f'ambjenti l-aktar impenjattivi. Kemm jekk tkun qed taħdem fil-manifattura, aerospazjali, żejt u gass, jew l-industrija tal-ikel, Kejbils termokoppja jipprovdu l-preċiżjoni u d-durabilità meħtieġa għal kompiti ta 'monitoraġġ tat-temperatura kritika.

Billi tagħżel il-kejbil tat-termokoppja t-tajjeb, In-negozji jistgħu jtejbu s-sigurtà, effiċjenza, u l-kwalità tal-prodott, Kollha filwaqt li tiżgura affidabilità fit-tul u kosteffikaċja.

When people hear the term mineral insulated cable, many immediately think of harsh environments like…

As telecommunication networks and power transmission systems grow rapidly, the demand for reliable and cost-effective…

In large-scale oil and gas projects, industrial cables are not just accessories—they are the "nervous…

In the world of electrical connections, cable lugs—also known as cable ears or cable terminals—huma…

When choosing the right rubber cable for an electrical engineering project, it is critical to…

Għeżież Imsieħba u Klijenti: 29 ta 'Jannar, 2025 Is-Sena l-Ġdida Lunar Ċiniża hija – Spring…