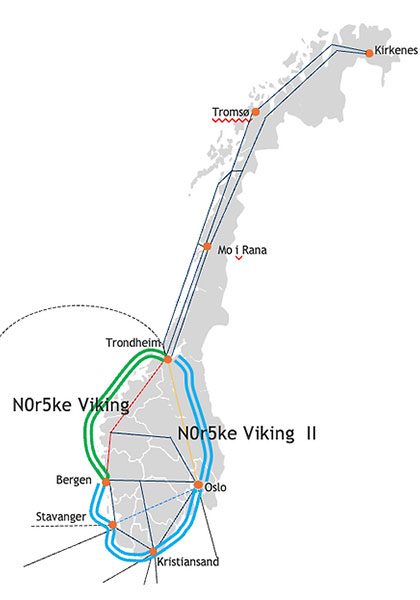

N0r5ke Fiber AS revealed plans for the second phase of Norway's digital infrastructure.

Riċentement, Fibra N0R5KE kif żvelat pjanijiet għat-tieni fażi tal-infrastruttura diġitali tan-Norveġja, li se tara l-kostruzzjoni ta ' 900 Sistema tal-kejbil tas-sottomarini KM li tgħaqqad Bergen u Oslo.

Se jkun hemm ukoll 500 KM Kejbil tal-Fibra Ottika Terrestri li jgħaqqad Oslo u Trondheim.

Meta tlestiet, Huwa rrappurtat li se jkun iffurmat ċirku ta 'fibra skura ta' 2,200 kilometru.

Iż-żewġ kejbils ġodda se jkun fihom mill-inqas 192 fibri li jgħaqqdu l-linji internazzjonali kollha tal-fibra sottomarini minn u lejn in-Norveġja u l-kbar, Ċentri tad-dejta stabbiliti fin-Norveġja.

Espansjoni taċ-Ċentru tad-Dejta Ekoloġika f'reġjun ġdid rikk fil-produzzjoni tal-enerġija ħadra.

L-espansjoni ta 'N0R5ke Viking jingħad li żżid b'mod sinifikanti s-sensja u d-disponibbiltà ta' fibra skura fin-Norveġja.

Hemm ukoll konnessjonijiet żejda ma 'bliet kbar, Hubs tal-konnessjoni, siti tal-inżul tal-kejbil, u reġjuni biex jipprovdu aċċess faċli għal klijenti internazzjonali.

L-eżistenti 810 kejbil sottomarini tal-Viking KM N0R5KE se jimxi tul il-kosta tal-punent tan-Norveġja minn Trondheim għal Bergen, ma ' 12 siti tal-inżul tul it-triq.

Allura kif jidher eżattament kejbil tal-fibra ottika? X'inhuma l-karatteristiċi ta 'kif jista' jkollu rwol daqshekk kbir? Hawn ħalli t-tim tal-kejbil ZMS iwasslek biex tifhem.

Kejbil tal-fibra ottika huwa tip ta 'kejbil ta' komunikazzjoni.

Tikkonsisti f'żewġ qlub tal-fibra ottika tal-ħġieġ jew aktar tal-plastik.

Dawn il-qlub tal-fibra ottika jinsabu fi overlay protettiv u huma koperti minn kmiem ta 'barra tal-PVC tal-plastik.

It-trasmissjoni tas-sinjal tul il-fibri ottiċi interni ġeneralment tuża dawl infra-aħmar.

F'Jannar 2013, Kuba għamlet bidla fil-komunikazzjonijiet billi fetħet kejbil tal-fibra ottika biex iżżid kanali barranin li jiġbdu l-attenzjoni.

Iċ-Ċina bdiet riċerka dwar il-kejbil tal-fibra ottika f'nofs is-snin sebgħin, kważi fl-istess ħin ma 'pajjiżi barranin, u żviluppa l-ewwel fibra tal-kwarz kmieni 1977.

Misjuqa mid-domanda għal kostruzzjoni ta 'komunikazzjoni fuq skala kbira fiċ-Ċina, L-industrija tal-kejbil tal-fibra ottika taċ-Ċina żviluppat malajr u ffurmat katina industrijali kompluta minn vireg tal-fibra ottika minn qabel għal prodotti tal-kejbil ottiku tal-fibra ottika.

Il-produzzjoni u s-saħħa teknika tal-kumpaniji tal-kejbil tal-fibra ottika taċ-Ċina kibru wkoll malajr, b'kapaċità ta 'żvilupp tal-prodott u kapaċità ta' innovazzjoni teknoloġika tjiebu aktar.

Iċ-Ċina saret it-tieni l-akbar pajjiż tal-kejbil tal-fibra ottika fid-dinja u laħqet il-livell avvanzat tad-dinja fl-aspetti kollha.

Dak li huwa iktar ta 'min jinnotah huwa li l-kostruzzjoni fuq skala kbira ta' 3G u l-bidu gradwali ta 'FTTH se jsiru l-fatturi ta' sewqan fit-tul għall-iżvilupp kbir tal-industrija tal-kejbil tal-fibra ottika taċ-Ċina taċ-Ċina, li żgur se jmexxi l-industrija tal-kejbil tal-fibra ottika taċ-Ċina f'ċiklu ġdid ta 'tkabbir.

Kuba fetħet l-ewwel tagħha kejbil tal-fibra ottika sottomarini, Li tagħmel il-veloċità tad-dejta unidirezzjonali f'Kuba ġiet imtejba.

Although there is still a long way to go to achieve the goal of “real freedom of access to the Internet”, Dan huwa tabilħaqq pass 'il quddiem fit-triq biex tinbidel f'Kuba.

Sadanittant, għall-ewwel darba fi kważi 50 snin, Cuban TV also simulcast foreign broadcasters’ TV programs on the 20th.

Kuba huwa bla dubju l-aħħar pajjiż fl-emisferu tal-Punent li jkun konness mal-kejbil tal-fibra ottika u għandu waħda mill-inqas rati ta 'konnettività tal-internet fid-dinja.

Preċedentement, Is-servizz tal-Internet ta 'Kuba kien prinċipalment konness permezz ta' sistema bis-satellita b'veloċità bil-mod ħafna.

Dwar 16 Perċentwali tal-Kubani għandhom aċċess għall-Internet, L-aktar minħabba li jużawha matul ix-xogħol u l-istudji tagħhom.

Madankollu, Ħafna minnhom jinsabu fuq il-LAN domestiku, li jistgħu jkunu soġġetti għal ħafna restrizzjonijiet.

Biss 2.9% ta 'Kubani għandhom aċċess mhux ristrett għal paġni tal-web minn madwar id-dinja fil-pajjiż.

1. Differenza materjali

Kejbils huma magħmula mill-metall (l-aktar ram u aluminju) bħala l-konduttur.

Fibra ottika tuża fibri tal-ħġieġ bħala l-konduttur.

2. Differenza tas-sinjal tat-trasmissjoni

Il-kejbil jittrasmetti s-sinjal elettriku. Fibra ottika tittrasmetti sinjali ottiċi.

3. Differenza tal-firxa tal-applikazzjoni

Il-kejbil issa huwa l-aktar użat għat-trasmissjoni tal-enerġija u t-trasmissjoni tad-dejta low-end (bħat-telefon).

Fibra ottika hija l-aktar użata għat-trasmissjoni tad-dejta.

1. Evidenza storika u prattika

Kejbil tal-aluminju ġie żviluppat u użat għal 43 snin minn dakinhar 1968 Fl-Istati Uniti.

L-użu tal-prodott kien pjuttost komuni, Is-sehem tas-suq tal-pajjiżi tal-Amerika ta ’Fuq laħaq 80%.

Wara 43 snin ta 'prattika wrew li l-użu tal-kejbil tal-liga tal-aluminju qatt ma seħħ falliment, u huwa sigur.

2. Ittestjar u Ċertifikazzjoni

Kejbil tal-liga tal-aluminju għadda l-ittestjar u ċ-ċertifikazzjoni tal-UL fl-Istati Uniti, Cul fil-Kanada, u Saiglobai fl-Awstralja.

Tinkludi wkoll iċ-Ċina Nazzjonali tal-Kejbil u l-Ittestjar tal-Wajer, L-Istitut ta 'Riċerka ta' Vultaġġ Għoli tal-Grid ta 'l-Istat Wuhan, il-materjali nazzjonali tal-bini tan-nar tas-superviżjoni tal-kwalità, u ċentru ta 'spezzjoni, u istituzzjonijiet awtorevoli oħra għall-ittestjar u ċ-ċertifikazzjoni.

3. Rwol ta 'kompożizzjoni ta' liga ta 'l-aluminju

3.1 Kompożizzjoni tal-konduttur tal-liga tal-aluminju miżjuda ma 'art rari u ħadid u komponenti oħra jtejbu bil-kbir il-konduttività elettrika u l-prestazzjoni tal-konnessjoni tagħha.

Speċjalment meta l-konduttur jiġi ttemprat iż-żieda tal-ħadid tipproduċi reżistenza għall-creep ta 'saħħa għolja.

Fil-każ ta 'tagħbija żejda kurrenti, Il-ħadid għandu rwol kontinwu ta 'konnessjoni sabiex il-konduttur tal-liga tal-aluminju ma jinqatax.

3.2 Creep huwa estremament ta 'ħsara għall-kejbil.

Jekk il-kejbil jitlaq, Il-punti ta 'kuntatt tiegħu mhumiex stretti biżżejjed, u l-pressjoni tonqos sabiex ir-reżistenza tal-kuntatt tiżdied malajr.

Il-fluss tal-kurrent jikkawża sħana żejda fil-ġogi.

Jekk mhux servis regolarment, Se jkun hemm perikli dwar is-sigurtà.

Huwa importanti ħafna li tissolva l-problema tal-creep tal-kejbil.

X'inhu creep?

Metall taħt l-azzjoni tat-temperatura, forzi esterni, u l-awto-piż.

Maż-żmien, bil-mod tipproduċi deformazzjoni permanenti li ma tistax tiġi rkuprata, Dan il-fenomenu huwa creep.

4. Prestazzjoni ritardanti tal-fjammi

Il-materjal ta 'insulazzjoni tal-kejbil tal-liga tal-aluminju jadotta polietilene cross-linked silane-rtardant tal-fjamma (XLPE), U l-proċess jadotta struttura ta 'armatura li tissakkar waħedha, li huwa ferm aħjar mill - għant tal-materjal tal-PVC fid-dissipazzjoni tas-sħana, u l-fjamma tista 'tinħela malajr, u n-nar jista 'jintemm malajr wara li l-fjamma tisparixxi, Allura l-prestazzjoni ritardanti tal-fjammi hija estremament eċċellenti. Kejbil tal-liga tal-aluminju jadotta materjali ġodda u teknoloġija ġdida biex jiżgura l-użu aktar sigur tiegħu.

Meta ż-żona trasversali tal-konduttur tal-liga tkun 1.5 drabi dak tar-ram, Il-proprjetajiet elettriċi tal-konduttur tal-liga u l-konduttur tar-ram huma l-istess, Il-kisba tal-istess kapaċità tat-tagħbija, reżistenza, u telf ta 'vultaġġ.

Ir-reżistività tal-liga tal-aluminju hija bejn l-aluminju u r-ram, ftit ogħla mill-aluminju, u inqas mir-ram.

Il-piż ta 'konduttur tal-liga tal-aluminju bl-istess tul huwa biss nofs dak tar-ram bl-istess rata ta' fluss trasversali.

Jekk il-konduttività elettrika tar-ram hija 100%, Il-konduttività tal-konduttur tal-liga hija dwar 61.2%.

Il-gravità speċifika tal-liga hija 2.7 u l-gravità speċifika tar-ram hija 8.9, Allura (8.9/2.7) x (0.612/1) = 2.

Jiġifieri, ir-reżistenza ta ' 2 Unitajiet ta 'piż tar-ram huwa l-istess bħar-reżistenza ta' 1 Massa tal-Unità tal-Alloy.

Għalhekk, Meta ż-żona trasversali tal-konduttur tal-liga tkun 1.5 drabi dak tar-ram, il-proprjetajiet elettriċi tiegħu huma l-istess.

Jiġifieri, l-istess fluss trasversali, reżistenza, u telf ta 'vultaġġ hekk kif jinkiseb ir-ram.

Ħafna fatturi jaffettwaw il-fluss trasversali tal-kejbils tal-enerġija.

Pereżempju

1. Karatteristiċi tal-linja

Bħalma huma l-kurrent operattiv, tip kurrenti, frekwenza, u fattur tat-tagħbija.

2. Wajer u struttura tal-kejbil

Bħall-istruttura tal-qalba konduttiva, in-numru ta 'qlub, it-tip ta 'materjal ta' insulazzjoni, l-istruttura u l-materjal tat-tarka u l-għant ta 'ġewwa u ta' barra, u d-dijametru estern totali.

3. Kundizzjonijiet ta 'tqegħid

Bħalma huma l-arja, Tqegħid tal-pipeline, Tqegħid midfun dirett, Tqegħid ta 'trinka taħt l-art, u t-tqegħid taħt l-ilma.

4. Kondizzjonijiet ambjentali tat-temperatura operattiva

Bħat-temperatura tal-arja u tal-ħamrija, Koeffiċjent tar-reżistenza termali tal-ħamrija, Effett ta 'prossimità tas-sorsi tas-sħana tal-madwar, eċċ.

Kejbil tal-liga tal-aluminju proċess ta 'produzzjoni, L-iktar teknoloġija avvanzata ta 'kompressjoni stretta fil-Ġermanja, sabiex il-fattur tal-mili tal-konduttur tiegħu jista 'jilħaq 93%.

U kejbils tal-liga tal-aluminju huma magħmula minn polietilene cross-linked silane, insulazzjoni li teħtieġ biss 2/3 tal-ħxuna tal-klorur tal-polivinil biex taqbeż bil-bosta l-prestazzjoni tal-insulazzjoni konvenzjonali.

Billi l-fattur tal-mili tar-ram jista 'jilħaq biss 80% B'mod ġenerali, L-insulazzjoni użata komunement hija l-PVC.

Għalhekk, Id-dijametru ta 'barra tal-kejbil tal-liga tal-aluminju jiżdied biss billi 11% jew inqas ibbażat fuq kejbil tar-ram, u jista 'jkollu l-istess prestazzjoni elettrika bħar-ram. Jista 'jidher li l-użu tal-kejbil tal-liga tal-aluminju m'għandux għalfejn jibdel id-disinn oriġinali tal-pajpijiet tal-użu tal-kejbil tar-ram.

Minħabba li d-disinjatur ġenerali jiddisinja d-daqs tal-pajpijiet li jbidu 150% tal-kejbil tar-ram.

Meta wieħed iqis il-problema ta 'żieda fil-kapaċità, Id-daqs tal-pajp tat-tqegħid jiżdied għal 200% tal-kejbil tar-ram, Allura mhix problema li tilbes il-pajp.

Materjal mhux manjetiku, Mhux se jipproduċi kurrent eddy u jista 'jnaqqas it-telf tal-linja.

Liga tal-aluminju b'materjal li jsakkar l-armatura huwa materjal mhux manjetiku.

Anki jekk hemm kurrent żbilanċjat bi tliet fażijiet, Mhux se jipproduċi kurrenti eddy, li jista 'jnaqqas it-telf tal-linja.

Kejbil tal-Fiber Optic, Kejbil tan-netwerk, Differenza tal-kejbil

Fil-ħardwer tan-netwerk, Hemm kategorija oħra li ma tistax tiġi injorata hija l-mezz ta 'trasmissjoni tan-netwerk, li ġeneralment insejħu kejbil tan-netwerk.

Il-kejbil tan-netwerk l-aktar komuni huwa maqsum f'par mibrum fin, kejbil tal-fibra ottika, kejbil koassjali, Kejbil koassjali oħxon, eċċ.

Kejbil tal-fibra ottika huwa ġenerazzjoni ġdida ta 'mezzi ta' trasmissjoni.

Meta mqabbel mal-midja tar-ram, Fiber Ottika kemm f'termini ta 'sigurtà, affidabbiltà, u l-prestazzjoni tan-netwerk tjiebu ħafna.

Barra minn hekk, Il-wisa 'tal-frekwenza tat-trasmissjoni tal-fibra ottika taqbeż ħafna dik tal-kejbil tar-ram.

U l-appoġġ tagħha tad-distanza massima ta 'konnessjoni ta' aktar minn żewġ kilometri hija l-għażla inevitabbli għall-formazzjoni ta 'netwerks fuq skala kbira.

Minħabba li l-kejbil tal-fibra ottika għandu l-vantaġġi ta 'interferenza anti-elettromanjetika tajba, kunfidenzjalità qawwija, veloċità mgħaġġla, kapaċità ta 'trażmissjoni kbira, eċċ.

Allura huwa wkoll iktar għali u rarament użat f'ambjenti domestiċi.

Hemm żewġ tipi differenti ta 'fibra ottika, fibra ta 'mod wieħed u fibra multimode, li huma aktar komuni.

The term “mode” refers to a bundle of light that enters the fiber at a certain angle.

1.1 Fibra multimode

Fibra multimode hija ġeneralment użata għall-konnessjonijiet tan-netwerk fl-istess bini ta 'uffiċini jew fil-viċinanza relattiva ma' xulxin.

1.2 Fibra ta 'mod wieħed

Fibra ta 'mod wieħed tagħti dejta ta' kwalità ogħla fuq distanzi itwal.

Ħafna drabi jintuża biex jgħaqqad bini ta 'uffiċini jew ma' netwerks imxerrda b'mod aktar wiesa '.

Jekk il-kejbil tal-fibra ottika jintuża bħala l-mezz ta 'trasmissjoni tan-netwerk, Tagħmir addizzjonali bħal transceivers ottiċi huma meħtieġa.

Għalhekk, L-investiment fl-ispejjeż huwa akbar u huwa inqas użat f'applikazzjonijiet ġenerali.

Kejbil ta 'par mibrum huwa kejbil ta' komunikazzjoni flessibbli li fih pari ta 'wajers tar-ram iżolati.

Huwa użat ħafna għax huwa kkaratterizzat mill-prezz baxx tiegħu.

Pereżempju, Aħna komunement naraw linji tat-telefon.

Jiddependi fuq ir-rata massima ta 'trasmissjoni, Kejbils tal-par mibruma jistgħu jinqasmu fi tliet livelli.

2.1 Kategorija 3 par mibrum

2.2 Kategorija 5 par mibrum

2.3 Kategorija Super 5 Par mibrum

Kategorija 3 Kejbil ta 'par mibrum għandu rata ta' 10MB / s, Kategorija 5 sa 100MB / s.

Kategorija Super 5 huwa sa 155MB / s jew aktar.

Dan huwa adattat għall-bżonnijiet futuri tat-trasmissjoni tad-dejta multimedjali, Allura huwa rrakkomandat li tuża kategorija 5 jew saħansitra kategorija super 5 kejbil ta 'par mibrum.

Il-kejbil ta 'par mibrum jista' wkoll jinqasam f'par protett protett (Stp) u par mibrum mhux imqaxxar (UTP).

Għalkemm ir-rata ta 'kejbil ta' par mibrum STP hija aktar baxxa (4MB biss / s), L-anti-interferenza minn kejbil ta 'par mibrum UTP, Allura l-prezz huwa wkoll ħafna iktar għali.

Dan it-tip ta 'kejbil ta' par mibrum irħis ftit dollari f'metru, Sewwa għalja jista 'jkun aktar minn għaxar dollari biex tixtri meter.

B'kuntrast, Il-prezz tal-kejbil tal-par mibrum UTP huwa ġeneralment f'metru ta 'dollaru jew hekk, relattivament irħis.

Barra minn hekk, Kejbils ta 'par mibruma ta' 10m u 100m użati b'mod komuni huma popolarment magħrufa bħala 10Base-T u 100Base-T.

U kejbil ta 'par mibrum jappoġġja l-użu ta' ras tal-kristall RJ45 użat biex jagħmel kejbil ta 'par mibrum u karta ta' netwerk RJ45 bejn il-konnettur.

Il-kwalità tagħha hija relatata direttament mal-istabbiltà tan-netwerk kollu, u ma jistax jiġi injorat.

Kejbil koassjali huwa aktar familjari għal ħafna ħbieb ta 'klassi ta' media ta 'trasmissjoni.

Huwa saff ta 'wajer iżolat imgeżwer madwar il-konduttur ċentrali tar-ram tal-linja tal-kejbil.

L-akbar karatteristika tagħha hija abilità tajba kontra l-interferenza, Dejta ta 'trasmissjoni stabbli, u wkoll irħis.

Allura darba kien użat ħafna, bħal linji tat-televiżjoni b'ċirkwit magħluq.

3.1 Vantaġġi

In-netwerk tal-istruttura tax-xarabank kompost minn kejbil koassjali huwa inqas għali u użat aktar fil-passat.

3.2 Żvantaġġi

Il-ħsara lil kejbil wieħed jista 'jwassal biex in-netwerk kollu jitniżżel, u l-manutenzjoni hija diffiċli.

Illum il-ġurnata, kejbil koassjali ma jintużax ħafna, Iżda għad hemm xi suq għal kejbil koassjali fin.

Il-linja tal-kejbil koassjali fina ġeneralment tinbiegħ fis-suq għal ftit dollari metru, li mhux għali wisq.

Barra minn hekk, Il-kejbil koassjali jintuża biex jgħaqqad mar-ras BNC.

Il-kejbil koassjali mibjugħ fis-suq ġeneralment huwa konness mar-ras BNC u l-prodott lest jista 'jintuża direttament.

Hawn fuq huwa introduzzjoni dettaljata għall-kejbil tal-fibra ottika. Bi żvilupp globali estremament rapidu, L-użu tal-kejbils qed jiżdied. U varjetà ta 'riżorsi tal-kejbil li jistgħu jintużaw b'mod sostenibbli qed jiġu żviluppati. ZMS Cable Company kienet imħassba dwar l-iżvilupp tal-kejbil, u dejjem taderixxi mal-provvista ta 'kejbils ta' kwalità għolja, Valur tajjeb għall-flus, servizz maħsub, prodotti wara kwalifika manwali stretta, affidabbli.

When choosing the right rubber cable for an electrical engineering project, it is critical to…

Għeżież Imsieħba u Klijenti: 29 ta 'Jannar, 2025 Is-Sena l-Ġdida Lunar Ċiniża hija – Spring…

Ir-ram wajer huwa komponent fundamentali fid-dinja tal-inġinerija elettrika u l-elettronika, valued…

Tħabbira lill-klijenti u l-imsieħba kollha, Riċentement, there has been sufficient evidence that other…

Fl-okkażjoni tas-Sena l-Ġdida 2025, ZMS Cable wishes every customer and partner a…

L-industrija medika Ewropea rat avvanzi sinifikanti f'dawn l-aħħar snin, driven by the integration…