The steel core aluminum stranded cable is a steel core aluminum stranded cable, which has the characteristics of simple structure, convenient erection and maintenance, mtengo wotsika, large transmission capacity, easy to cross rivers and valleys and other special geographical conditions, as well as good electrical conductivity, sufficient The mechanical strength and tensile strength are high, which can increase the distance between the towers. Choncho, it is widely used in overhead transmission and distribution lines of various voltage levels.

Information on ACSR—Aluminum Conductor Steel Reinforced

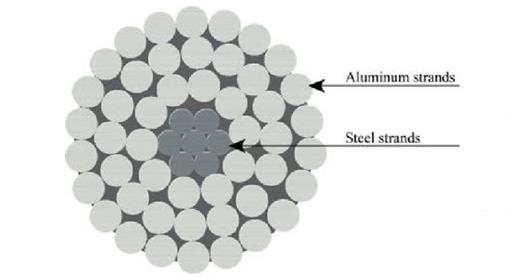

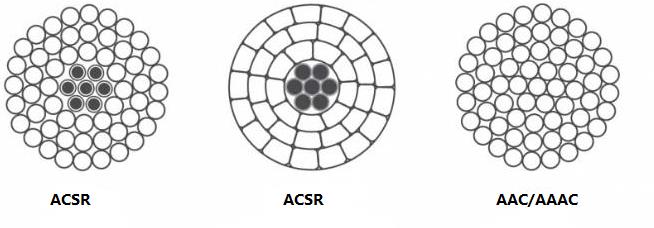

Aluminum reinforced conductors are concentric stranded conductors with one or more layers of hard-drawn 1350-H19 aluminum wire on a galvanized steel wire core. Depending on the size, the core wire can be single or stranded. Steel core wire is available in grade A, B, or C zinc plated for corrosion protection. Additional corrosion protection can be obtained by applying grease to the core wire or injecting grease into the finished conductor. The ratio of steel and aluminum in the Mtengo wa ACSR conductor can be selected based on the mechanical strength and current-carrying capacity required for each application. ACSR conductors are recognized for their economy, reliability, and good strength/weight ratio.

Differences Between AAC, Chithunzi cha AAAC, and ACSR Aluminum Conductors

AAC, Chithunzi cha AAAC, and ACSR are part of the family of overhead conductors, transmission conductors, and distribution conductors. The official names for these cables are all aluminum conductor (AAC), all-aluminum conductor (Chithunzi cha AAAC), and aluminum conductor steel reinforced (Mtengo wa ACSR). These overhead aluminum conductors are used as transmission and distribution lines. All aluminum conductors consist of one or more strands of aluminum wire, depending on the application. Due to its high corrosion resistance, it can be used in coastal areas and is also widely used in the railway and subway industries. All aluminum alloy conductor is used as bare conductor cable where larger overhead circuits are required, mechanical resistance than AAC, and better corrosion resistance than ACSR.

The sag characteristics and strength-to-weight ratio of AAAC conductor cables are superior to AAC and ACSR. Higher-strength acsr conductors are commonly used across rivers, overhead ground wires, and installations involving very long spans. ACSR conductors can be manufactured with different tensile strengths for any given resistance. So the high tensile strength combined with its lightweight nature means it can cover longer distances with less support. Due to the larger diameter of the ACSR conductors, a higher corona limit can be obtained, which is beneficial for HV and EHV overhead lines.

ACSR conductors combine the lightweight and good electrical conductivity of aluminum with the high tensile strength and robustness of steel. Inline design, provides higher tension, less sag, and longer span lengths than most other types of overhead conductors. Our factory supplies ACSR on non-recyclable wood/steel reels or recyclable steel reels according to customer requirements.