AAC AAAC ACSR

Kabel VERI, according to different uses, produces a variety of overhead cables. Including AAC, AAAC, ACSR, Kabel ABC –aerial bundled cable, i tak dalej. Our range of overhead lines generally contains aluminum conductors or aluminum alloy conductors to meet all customer needs. We specialize in providing excellent overhead lines for transmission, dystrybucja, and power network industries. And other cable products such as voltage cables, submarine cables, fiber cables, special cables, i tak dalej. So please contact us with your requirements. Również, we will reply to you the detailed information that you want.

Types of VERI AAC AAAC ACSR

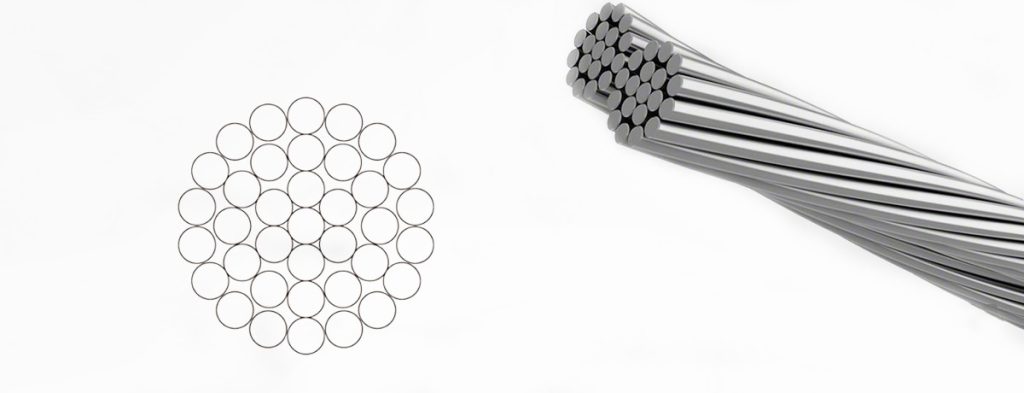

All Aluminum Conductor—AAC

Aluminium Alloy Dyrygent is the main component of the overhead power line. Its function is to transmit current and electric power. These bare conductors are suitable for low, średni, and high-voltage overhead lines. AAC is widely used in urban areas, where the span is usually short. But the conductivity requirements are high.

STANDARDY&REFERENCES:ASTM—B 230, ASTM—B 231, DIN48201, BS215 (Or producing by the standard of the customer’s country)

- Phase conductors: round stood or compacted 1350-H19 aluminum or copper conductor, AAAC, ACSR

- Neutral or messenger conductor: round stood or compacted 6201 aluminum alloy or AAC, ACSR

- Konduktor oświetlenia ulicznego: round stood or compacted aluminum conductor

- Izolacja: LDPE, HDPE, XLPE, PCV

Manufacturing Standards

Conductor Size | Code Words | Klasa | Required Construction | Mass | Rated Strength | |||||

Cmils or AWG | mm² | NIE. of Wires | Diameter of Wire | Per 1000ft, lb | Per km, kg | kips | kn | |||

W. | mm | |||||||||

3500000 | 1773 | Bluebonnet | A | 127 | 0.1660 | 4.22 | 3345 | 4977 | 58.7 | 261 |

3000000 | 1520 | Trillium | A | 127 | 0.1537 | 3.90 | 2840 | 4226 | 50.3 | 223 |

2750000 | 1393 | Bitterroot | A | 91 | 0.1738 | 4.42 | 2602 | 3872 | 46.1 | 205 |

2500000 | 1267 | Lupine | A | 91 | 0.1657 | 4.21 | 2365 | 3519 | 41.9 | 186 |

2250000 | 1140 | Sagebrush | A | 91 | 0.1572 | 3.99 | 2128 | 3166 | 37.7 | 167 |

2000000 | 1013 | Cowslip | A | 91 | 0.1482 | 3.77 | 1873 | 2787 | 34.2 | 153 |

1750000 | 886.7 | Jessamine | AA | 61 | 0.1694 | 4.30 | 1641 | 2442 | 29.7 | 132 |

1590000 | 805.7 | Coreopsis | AA | 61 | 0.1614 | 4.10 | 1489 | 2216 | 27.0 | 120 |

1510500 | 765.4 | Gladiolus | AA,A | 61 | 0.1574 | 4.00 | 1417 | 2108 | 25.6 | 114 |

1431000 | 725.1 | Carnation | AA,A | 61 | 0.1532 | 3.89 | 1342 | 1997 | 24.3 | 108 |

1351000 | 694.8 | Columbine | AA,A | 61 | 0.1488 | 3.78 | 1266 | 1884 | 23.4 | 104 |

APLIKACJA

All aluminum conductors belong to bare conductors, which mainly play the role of transmitting electrical energy. Based on different voltages, the wire cross-sectional area is also different. AAC cable is commonly used for general distribution lines with a small force and small span. But it is not allowed to contact with trees.

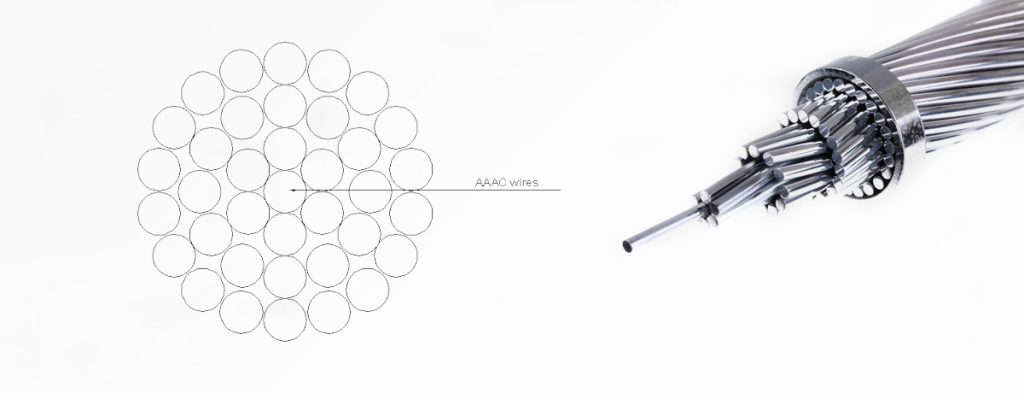

All Aluminum Alloy Conductor—AAAC

Dyrygent: Hard-Drawn 1350-H19 Aluminum Wires, Minimum Purity 99.45%.

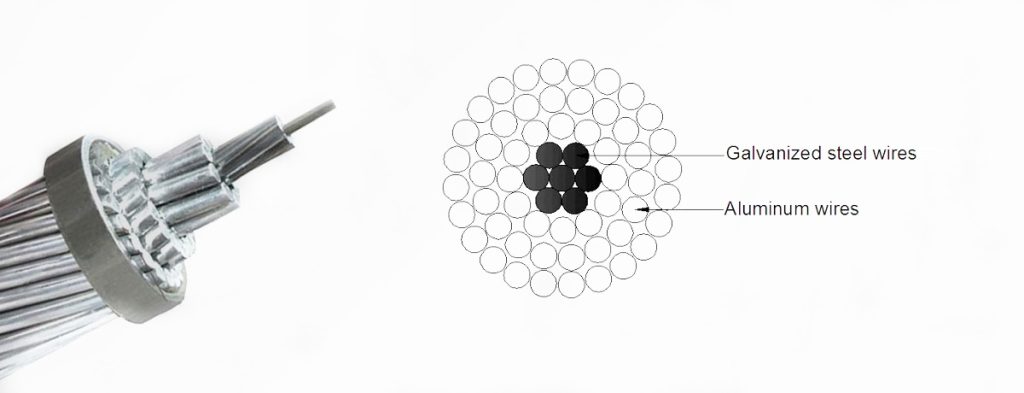

Reinforcement: Galvanized Steel Wires (Zinc-Coated)

Construction (Aluminum/Steel): 6/1, 7/1, 8/1, 12/7, 16/19, 24/7, 26/7, 30/7, 30/19, 36/1, 45/7, 54/7, 54/19, 72/7, 76/19, 84/19

Cross-Sectional Area: 6~4/0 awg, 80~2312 mcm (80~211.3 mcm for Standard High-Strength Conductor).

Galvanization: Class A, B or C

Grease Corrosion Protection: Available upon Request

Specifications

AAAC bare conductor meets the following ASTM specifications :

B-398 Aluminum Alloy 6201-T81 Wire for Electrical Purposes

B-399 Concentric-Lay-Stranded 6201-T81 Aluminum Alloy Conductors.

The Part of AAAC-ASTM-B399 Technical Data:

Stranding | Diameter of conductor | Linear mass | Rated strength | D.C. resistance at 20℃ |

No./mm | mm | Kg/km | kgf | Ω/km |

6 | 7/1.55 | 4.65 | 36.44 | 422 |

7/1.68 | 5.04 | 42.7 | 502 | |

4 | 7/1.96 | 5.89 | 57.89 | 685 |

48.69(4) | 7/2.12 | 6.35 | 67.56 | 799 |

2 | 7/2.47 | 7.42 | 92.14 | 1091 |

77.47(2) | 7/2.67 | 8.02 | 107.50 | 1275 |

1/0 | 7/3.12 | 9.35 | 146.50 | 1733 |

123.3(1/0) | 7/3. 37 | 10.11 | 171.00 | 2019 |

2/0 | 7/3.50 | 10.52 | 184.70 | 2090 |

155.4(2/0) | 7/3.78 | 11.35 | 215.16 | 2447 |

3/0 | 7/3.93 | 11.79 | 232.70 | 2641 |

195.7 (3/0) | 7/4.25 | 12.75 | 271.50 | 3079 |

4/0 | 7/4.42 | 13.26 | 293.70 | 3334 |

246.9 (4/0) | 7/4.77 | 14.30 | 342.60 | 3885 |

Aplikacja:

Used as bare overhead conductor for primary and secondary distribution. The AAAC conductor is designed to get a better strength-to-weight ratio and offer improved electrical properties, excellent sag-tension characteristics, and superior corrosion resistance when compared with ACSR. As compared to a conventional ACSR conductor, the lighter weight, comparable strength & current carrying capacity, lower electrical losses, and superior corrosion resistance have given AAAC a wide acceptance in the distribution and medium & high voltage transmission lines.

Aluminum Conductor Steel Reinforced—ACSR

ACSR conductor has the advantages of simple structure, convenient erection and maintenance, low line cost, i dużą zdolność przesyłową. And they are convenient for laying across special geographical conditions. Such as rivers and valleys, dobra przewodność elektryczna, and sufficient mechanical.

Design

1 Aluminum conductor with increased breaking load, round stranded compressed (RM)

2 Core insulation (XPLE black, UV-resistant, not flame retardant); 2 up to 4 cores of the equal cross-section are stranded together in left-hand lay, additionally 1 Lub 2 cores of the reduced cross-section can be co-stranded.

STANDARDY&REFERENCES:ASTM—B 230, ASTM—B 231, DIN48201, BS215 (Or producing by the standard of the customer’s country)

ACSR Technical Characteristics / U.S.A Sizes – ASTM B232

Area | Stranding and diameter | Approximate overall diameter | ||||

Aluminium | Steel | Total | Aluminium | Steel | ||

AWG or MCM | mm2 | mm2 | mm2 | mm | mm | mm |

8 | 8.34 | 1.39 | 9.73 | 6/1.33 | 1/1.33 | 3.99 |

6 | 13.29 | 2.19 | 15.48 | 6/1.68 | 1/1.68 | 5.04 |

4 | 21.16 | 3.55 | 24.71 | 6/2.12 | 1/2.12 | 6.36 |

4 | 21.16 | 5.35 | 26.50 | 7/1.96 | 1/2.61 | 6.53 |

3 | 26.69 | 4.45 | 31.14 | 6/2.38 | 1/2.38 | 7.14 |

2 | 33.61 | 5.61 | 39.22 | 6/2.67 | 1/2.67 | 8.01 |

2 | 33.61 | 8.52 | 42.13 | 7/2.47 | 1/3.30 | 8.24 |

1 | 42.39 | 7.10 | 49.49 | 6/3.00 | 1/3.00 | 9.00 |

0 | 53.48 | 8.90 | 62.38 | 6/3.37 | 1/3.37 | 10.11 |

2/0 | 67.42 | 11.23 | 78.65 | 6/3.78 | 1/3.78 | 11.34 |

3/0 | 85.03 | 14.19 | 99.22 | 6/4.25 | 1/4.25 | 12.75 |

4/0 | 107.23 | 17.87 | 125.10 | 6/4.77 | 1/4.77 | 14.31 |

Application of ACSR

1. The higher-strength ACSR conductors are widely used in power transmission lines with various voltage levels.

2. The higher-strength ACSR conductors are commonly used for river crossings, overhead earth wires, and installations involving extra-long spans.

3. The higher-strength ACSR conductors are also suitable for laying across rivers and valleys where special geographical features exist.

Doskonała obsługa kabla VERI

Doświadczenie eksportowe

Jako profesjonalny producent kabli, nasze produkty kablowe były w przeszłości eksportowane do wielu krajów 30 lata, w tym USA, Kanada, Hiszpania, Wielka Brytania, Niemcy, Francja, Rosja, Grecja, Arabia Saudyjska, itp. W tych krajach, nasze produkty kablowe cieszą się dużą popularnością wśród klientów. I co roku, ze względu na naszą dobrą jakość i obsługę, otrzymalibyśmy wiele dobrych opinii od naszych klientów.

Indywidualna usługa kablowa

W zakres naszych usług niestandardowych wchodzi projektowanie, rozmiar, i kolor powierzchni. Dostępnych jest również wiele popularnych kolorów. Specjalizujemy się również w nadposzyciu, Na przykład, możemy wykonać niestandardowy polietylen (PE) i poliuretan (PUR) zgodnie z Twoimi wymaganiami. Możemy dostarczyć rozwiązania w oparciu o Twoje pomysły. Skontaktuj się z nami, aby przekazać nam swój pomysł.

Surowe standardy kontroli jakości

Veri Cable oferuje szeroką gamę kabli zasilających w oparciu o trendy i osobiste preferencje. Dostarczamy wszelkiego rodzaju kable zasilające, ponad 100 szereg. Następnie, aby zapewnić jakość kabli, nalegamy na testowanie naszych produktów od czasu do czasu.