Cabo de halogênio zero zero de fumaça baixa

O cabo livre de fumaça e halogênio fornecido pelo cabo Veri tem Excelentes propriedades retardantes da chama, quase sem fumaça e sem gases corrosivos escapando ao queimar. Eles são amplamente utilizados em usinas nucleares, Estações de metrô, trocas telefônicas e centros de controle de computador, arranha-céus, hotéis, estações de rádio e televisão, Instalações militares importantes, plataformas de petróleo, e outros locais densamente povoados com baixa densidade do ar.

O diâmetro de flexão de Cabo LSZH não é menor que 15 tempos do diâmetro externo do cabo, e o diâmetro de flexão do cabo único não é menor que 20 vezes. Outros podem ser personalizados, Inquérito grátis é bem -vindo.

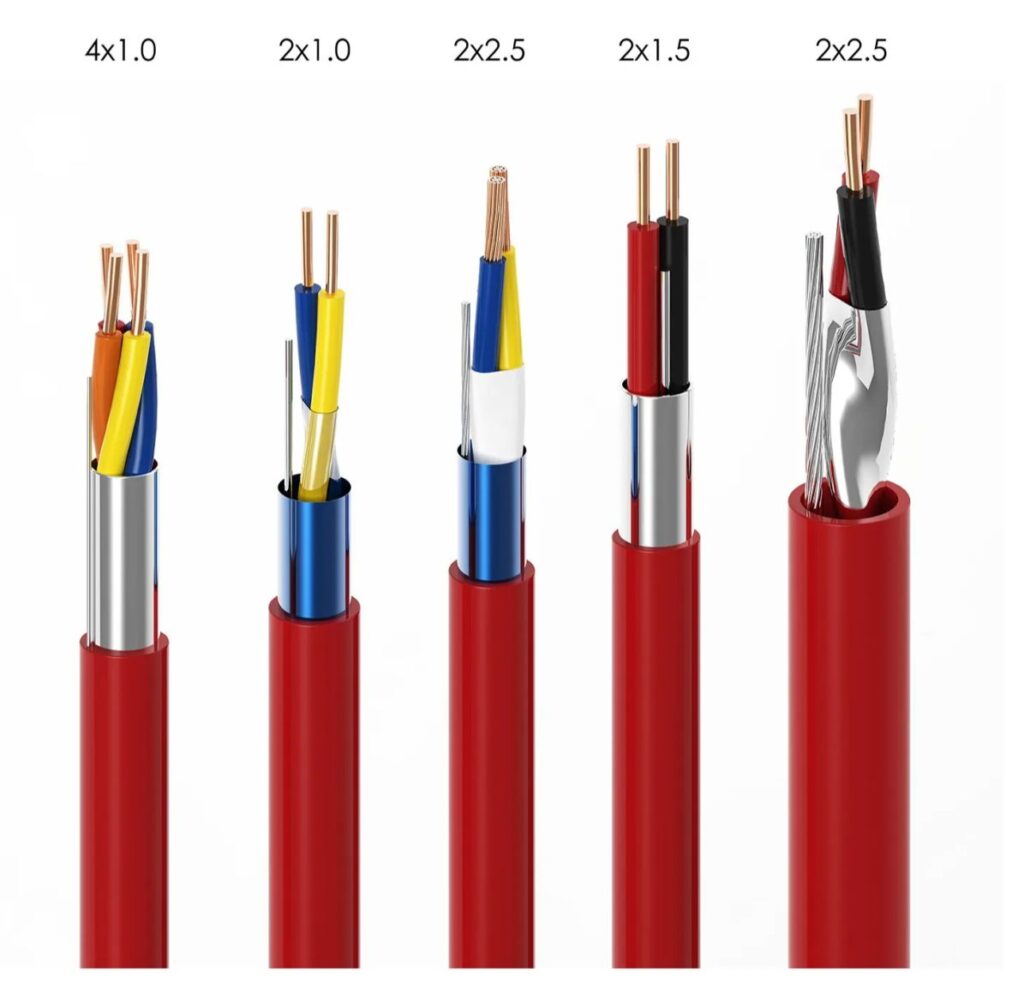

Tipos de cabos de halogênio zero zero fumaça baixa

Controlar & Comunicação Cabos LSZH: A baixa fumaça e o halogênio livre é uma propriedade que os cabos podem ter alterando o material. Nos cabos de controle e de comunicação, Muitos cabos também incorporam propriedades sem fumaça e halogênio no material para melhorar sua segurança quando usadas em locais públicos.

Então o cabo LSZH tem muitos tipos de especificações de parâmetros, Dependendo de quais funções você precisa para realizar em seu projeto.

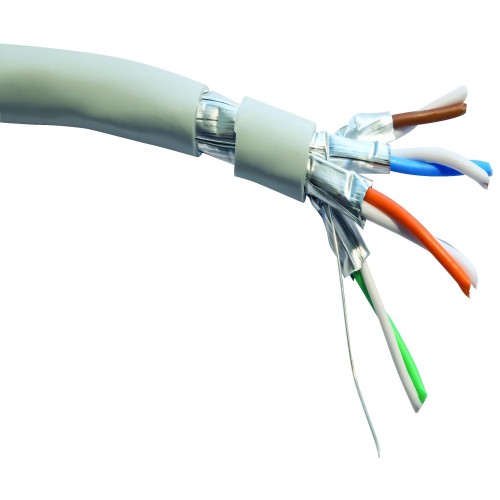

Cabo LSZH CAT6

Condutor: Aula 1 condutor sólido de cobre

Isolamento: HDPE (Polietileno de alta densidade)

Bainha: LSZH (Baixa fumaça e zero halogênio)

PADRÕES: Retardador de chama de acordo com o BS EN/IEC 60332-1-2

CARACTERÍSTICAS

Classificação de temperatura: Fixo: -20° C a +60 ° C.

Raio mínimo de flexão: Fixo: 4 x diâmetro geral, Flexionado: 8 x diâmetro geral

Este cabo de alto desempenho de 4 pares que consiste em condutores de pares torcidos é usado principalmente para transmissão de dados. Apoiando todo o equipamento mais recente, Ele suporta uma faixa de frequência de até 250 MHz e velocidades de transmissão de até 1 Gigabit por segundo. Ideal para instalações onde fogo, Emissões de fumaça e fumaça tóxica representam um perigo potencial para a vida e o equipamento.

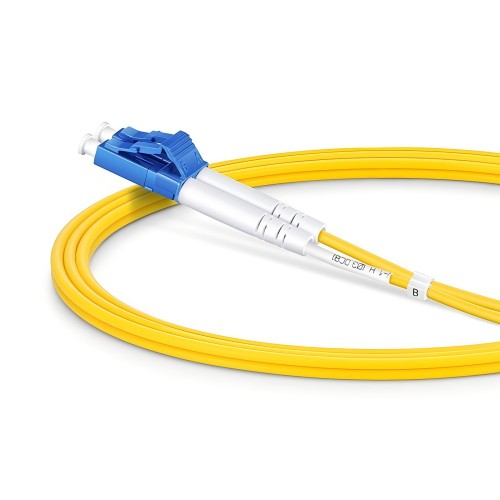

Cabo de fibra óptica LSZH

ESTRUTURA: Modo único、Fibra、Fio de bloqueio de água、Tubo solto、Fio de vidro、Cst、Jaqueta lszh

- Cada fibra está equipada com marcadores A/B para identificar as portas de transmissão e recebimento para garantir a conexão adequada do sistema

- Usado para conectar-se a painéis de patch e/ou equipamentos de rede usando conectores do tipo LC que exigem 9/125 Cabos SingleMode LSZH

- Os conectores são polidos para PC

- LSZH (Baixa fumaça, Sem halogênio) A jaqueta tem fumaça mínima e não produz gases de halogênio tóxicos

É usado para transmissão de sinal de sistemas de controle elétrico, como controle de equipamentos em fábricas automatizadas e sistemas de controle de elevadores. Ele garante que os sinais de controle possam ser efetivamente transmitidos por um certo período de tempo em caso de emergência como fogo, para que o equipamento possa ser interrompido com segurança ou a operação de emergência pode ser realizada.

Cabos LSZH isolados de PE

Condutor: Cobre sólido recozido ou cobre encalhado liso

Isolamento: Composto PE

Camada de armadura integral: Fio de alumínio/cobre

Bainha Externa: LSZH

Classificação de tensão: 300V

PADRÕES: EM 50288-7

Tipicamente, Este cabo retardador de chama LSZH é geralmente usado para instalações internas, comunicação, Sinais e serviços de transmissão de dados e de voz em fábricas de processamento e fabricação industriais em áreas úmidas, e também para interconectar equipamentos elétricos e instrumentação para reduzir a emissão de fumos tóxicos.

Padrões de retardamento da chama: EM 60332-1-2; CEI 60332-1-2; Bs um 60332-1-2; VDE 0482-332-1; Nbn c 30-004 (gato. F1); NF C32-070-2.1(C2); o 20-35/1-2; EM 50265-2-1*; De vde 0482-265-2-1*

Cabo LSZH isolado de borracha de silicone

Condutor: Condutor de cobre em estanho ou sólido.

Isolamento: Borracha de silicone

Tensão nominal: 600 volts.

Vantagem: Espessura uniforme do fio, fácil de tirar e cortar, Passa Ul VW-1 & Cul FT1 Teste de chama vertical, condutores revestidos de superfície disponíveis.

Adequado para eletrodomésticos, iluminação, Metalurgia e faróis, motores, sensores de temperatura, série militar, Série metalúrgica e química, Automotivo e fuzileiro naval, instalações elétricas.

Padrões de retardamento da chama: EM 60332-1-2; CEI 60332-1-2; Bs um 60332-1-2; VDE 0482-332-1; Nbn c 30-004 (gato. F1); NF C32-070-2.1(C2); o 20-35/1-2; EM 50265-2-1*; De vde 0482-265-2-1*

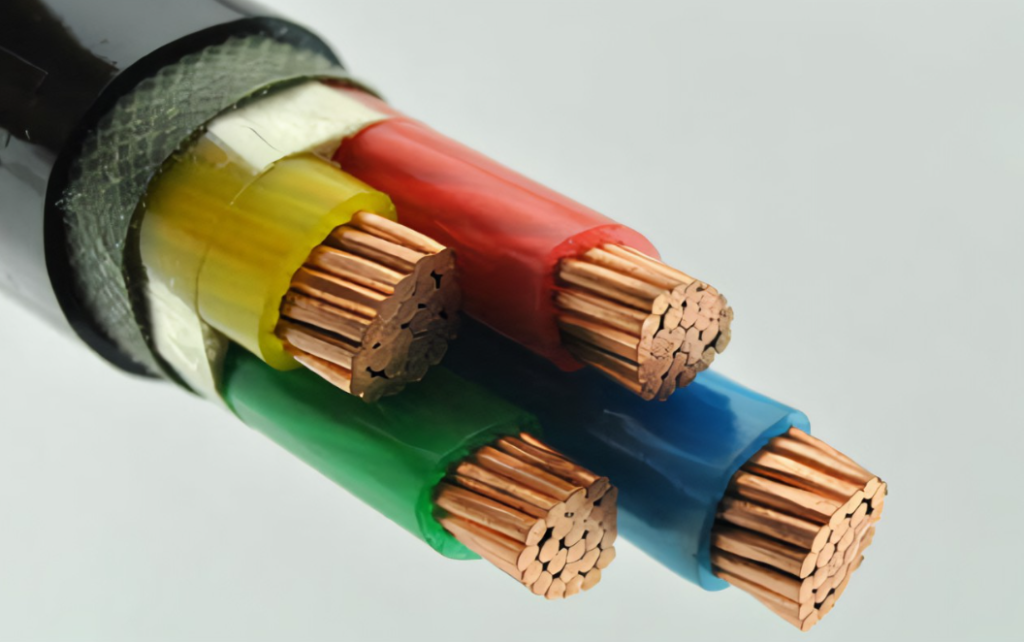

LSZH XLPE Cabo de cobre à prova de fogo

WDZN-YJV CORE POLETILENO POLETILENO PVC ISULADO Cabo de alimentação resistente à bainha protetora do anel. Quando colocado dentro de casa, em túneis e pipelines, O cabo não pode suportar forças externas mecânicas. Os cabos de núcleo não podem ser colocados em pipelines de material magnético. Os cabos resistentes ao fogo são fabricados de acordo com os padrões corporativos. O desempenho resistente ao fogo dos cabos atende aos requisitos da GB nacional padrão 1266.6, e é dividido em duas categorias diferentes resistentes ao fogo, A e b (950℃ ~ 1000 ℃/90 min, 750℃ ~ 800 ℃/min). Os cabos de chama de baixo e baixo halogênio são fabricados de acordo com os padrões corporativos. O desempenho retardante da chama do cabo atende aos requisitos do padrão nacional GB1266.5. A transmitância de luz não é menor que 35%, e a liberação de cloreto de hidrogênio não é superior a 100mg/g.

Aplicativo | Dentro de casa, túneis e tubos |

Tipo | Cabo de alimentação |

Certificado | CCC CE IEC |

Condutor | Cobre |

Isolamento | XPLE+resistente ao fogo |

Bainha | LSZH |

Tensão | 0.6/1.0kV |

Embalagem | Rolar |

Requisitos de isolamento dos cabos LSZH

Combustível sem foda-fumado

O grau de resistência à temperatura da bainha retardante de chamas de halogênio sem foda baixa foda tem 70 ℃ e 90 ℃, geralmente requer um índice de oxigênio do produto de mais de 32, tem bom desempenho mecânico e desempenho de processamento, pode ser amplamente utilizado em cabo de alimentação, Cabo de comunicação, cabo de controle, Cabo marinho E outra camada de bainha.

Baixa fumaça HAlogen livre Ccapaz Fmuito ruim Retardante EUisolante Mmaterial

As propriedades de materiais isolantes de baixa foda-foda sem foda-halogênio são semelhantes aos de materiais de revestimento sem fumantes com baixo teor de halogênio, e os requisitos de desempenho de isolamento são maiores. Pode ser usado para a camada isolante de poder, comunicação, e fios eletrônicos.

euOW-Smoke HAlogen livre Fmuito ruim Retardante Ccapaz Fmuito ruim Retardante Óxygen Barrier

O material é usado para a camada de bainha interna de cabos de energia com requisitos retardantes de alta chama, o que pode melhorar o efeito retardador geral da chama do cabo e reduzir adequadamente os requisitos retardantes da chama para a camada de bainha de isolamento de cabo.

Sobre o serviço pós-venda da VERI Cable

Primeiro, Compromisso de Qualidade do Produto:

- Existem registros de qualidade e dados de testes para a fabricação e testes de todos produtos de cabo.

- Para a inspeção do desempenho do produto, sinceramente convidamos os usuários a inspecionar pessoalmente todo o processo e desempenho do produto. Depois que o produto for confirmado como qualificado, ele será embalado e enviado.

Segundo, o compromisso de preço do produto:

- Para garantir a alta confiabilidade do produto, a seleção de materiais do sistema é feita de produtos nacionais ou de alta qualidade.

- Sob as mesmas condições competitivas, nossa empresa forneceremos sinceramente a você um preço acessível sem reduzir o desempenho técnico do produto ou alterar os componentes do produto.

- Compromisso de prazo de entrega:

Terceiro, Prazo de entrega do produto:

Tanto quanto possível de acordo com os requisitos do usuário, se houver requisitos especiais que precisam ser preenchidos com antecedência, nossa empresa pode organizar especialmente a produção e instalação, e nos esforçamos para atender às necessidades do usuário.

Quarto, compromisso de serviço pós-venda:

- Princípio de serviço: rápido, decisivo, preciso, atencioso e minucioso.

- Objetivos de serviço: qualidade de serviço para conquistar a satisfação do cliente.

- Eficiência do serviço: Se o equipamento falhar dentro do período de garantia ou fora do período de garantia, depois que o fornecedor for notificado, o pessoal de manutenção pode chegar ao local e iniciar a manutenção dentro 24 horas.

- Princípio de serviço: O período de garantia dos produtos a cabo é de doze meses. Durante o período de garantia, o fornecedor reparará e substituirá gratuitamente as peças danificadas por motivos de qualidade. Se as peças estiverem danificadas fora do período de garantia, os acessórios fornecidos cobrarão apenas o custo do custo dos danos ao equipamento causados por fatores humanos do comprador, e os acessórios reparados ou fornecidos pelo fornecedor são calculados ao custo.