Concêntrico & Cabo dividido

Cabos concêntricos são compostos de condutores de núcleo único ou multicore, e há uma camada de isolamento entre os múltiplos condutores, que podem efetivamente impedir a interferência eletromagnética entre os dois condutores.

Cabos concêntricos produzidos na Veri são típicos da maioria Tipos de isolamento de cabo. Os cabos concêntricos são frequentemente usados como cabos de fornecimento de energia. Mais comum na distribuição de energia, painel, e áreas de iluminação de rua.

Modelos populares de cabo concêntrico

Cabo Concêntrico LV

Condutor: Classe de cobre 2

Isolamento: XLPE / PVC

Essencial: Núcleo único

Bainha interna do cabo: PVC

Camada Condutora Concêntrica: Cobre

Fita de cabo: Material sem absorvente ou OEM

Blindado: Awa

Bainha externa do cabo: XLPE / PVC / Educação Física / LSZH

Cabo concêntrico de alumínio

Padrão: ASTM-B; ASTM-D; UL

Condutor: 8000 Liga de alumínio da série

Isolamento: XLPE / PVC

Essencial: Núcleo único

Bainha interna do cabo: PVC

Camada Condutora Concêntrica: Alumínio

Fita de cabo: Material sem absorvente ou OEM

Blindado: Awa

Bainha externa do cabo: XLPE / PVC / Educação Física / LSZH

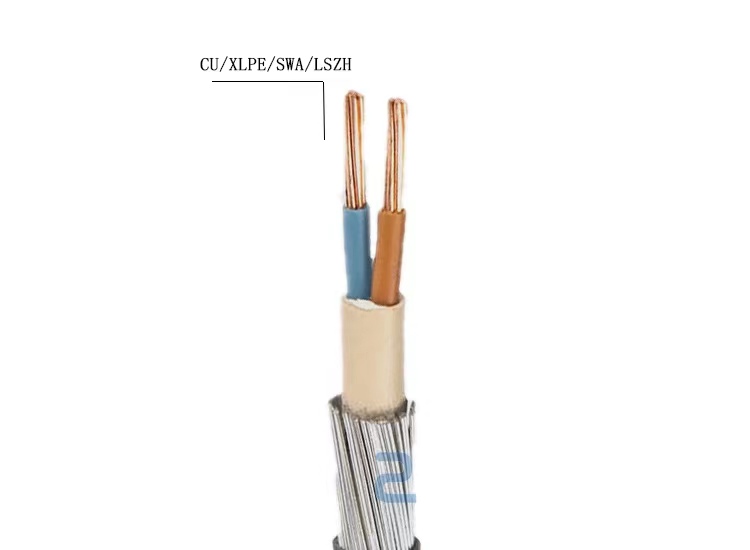

LSZH Cabo concêntrico dividido

Condutor: Alumínio / Condutor de cobre

Isolamento: XLPE

Essencial: Solteiro / Dois / Três / Quatro núcleo

Bainha interna do cabo: PVC

Camada Condutora Concêntrica: Cobre / Alumínio

Fita de cabo: Material sem absorvente ou OEM

Bainha externa do cabo: LSZH

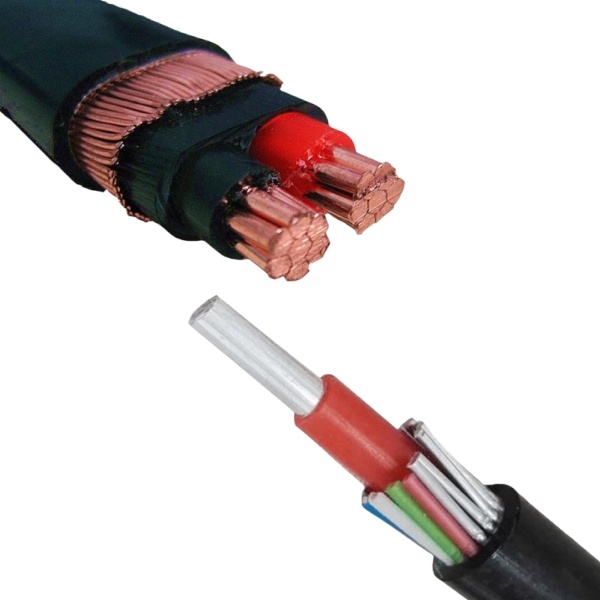

Cabo concêntrico de três/quatro núcleo

Condutor: Alumínio / Condutor de cobre

Isolamento: XLPE

Essencial: Três / Quatro núcleo

Bainha interna do cabo: PVC

Camada Condutora Concêntrica: Cobre/alumínio

Fita de cabo: Material sem absorvente ou OEM

Bainha externa do cabo: XLPE / PVC / Educação Física

Aplicação de cabo

Este cabo concêntrico de condutor de cobre/alumínio é usado em linhas de distribuição de energia da tensão nominal 600/1000V e abaixo como o cabo de conexão da fonte de energia ao medidor de eletricidade. Os cabos condutores concêntricos são adequados para uso em locais secos e úmidos, diretamente subterrâneo ou ao ar livre. A temperatura máxima de trabalho é de 70 ° C (Isolamento de PVC ou PE) ou 90 ° C. (Isolamento XLPE).

Os cabos de condutores concêntricos blindados têm melhor resistência mecânica. Quando enterrado no chão, Isso aumenta sua capacidade de suportar tensões, reduz os danos causados por forças externas, e garante que cabos e equipamentos vinculados funcionem com eficiência.

Especificações do cabo

Número de núcleos: 1, 2, 3, 3+1, 3+2, 4, 4+1, 5 e assim por diante.

Tipo | Tamanho | Construção | |||||

AWG | Condutor de Fase | XLPE(milímetros) | Condutor neutro | UV-PVC(milímetros) | |||

Não. | Sim. | Espesso | Não. | Sim. | Espesso | ||

Bipolar | 12 | 7 | 0.78 | 1.14 | 39 | 0.321 | 1.14 |

10 | 7 | 0.98 | 1.14 | 25 | 0.511 | 1.14 | |

8 | 7 | 1.23 | 1.14 | 25 | 0.643 | 1.14 | |

6 | 7 | 1.55 | 1.14 | 25 | 0.813 | 1.14 | |

4 | 7 | 1.96 | 1.14 | 27 | 1.02 | 1.14 | |

Tripolar | 8 | 7 | 1.23 | 1.14 | 65 | 0.45 | 1.14 |

6 | 7 | 1.55 | 1.14 | 65 | 0.511 | 1.52 | |

4 | 7 | 1.96 | 1.14 | 65 | 0.643 | 1.52 | |

2 | 7 | 2.47 | 1.14 | 65 | 0.823 | 1.52 | |

Tipo | Tamanho | Construção | |||||

mm2 | Condutor de Fase | XLPE(milímetros) | Condutor neutro | UV-PVC(milímetros) | |||

Não. | Sim. | Espesso | Não. | Sim. | Espesso | ||

Bipolar | 10 | 7 | 1.35 | 1.2 | 13 | 0.98 | 1.0 |

6 | 7 | 1.1 | 1.2 | 18 | 0.654 | 1.0 | |

Se você não sabe como escolher o produtos Você precisa ou não encontra o tipo de cabo e o tamanho que você precisa nesta página, não se preocupe. Entre em contato conosco e envie -nos seus requisitos, e podemos ajudá -lo a escolher o cabo certo. Você pode nos fornecer as seguintes informações: tensão do cabo, Material do condutor, Material de isolamento e bainha, tipo de blindagem, Tipo de armadura, etc.. ou você pode nos fornecer um ambiente de instalação de cabos, Requisitos de aplicação, etc.. Nós o serviremos de todo o coração. Fornecedor de cabo Veri tem várias certificações de qualidade: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, CEI, Bobagem, NFC, ASTM, DE, etc..

Excelente serviço de cabo VERI

VERI Cable tem várias maneiras de proteger seus cabos, com embalagem de remessa resistente e profissional e seguro abrangente. Antes do envio, nosso cabos são embalados em bobinas de madeira e bobinas de caixa de papelão ondulado. Durante o transporte, para proteger as extremidades do cabo da umidade, selamos com fita autoadesiva BOPP e não higroscópica.

Se houver problemas de qualidade, como embalagens danificadas e danos na superfície do produto no local quando as mercadorias forem recebidas, se as mercadorias forem confirmadas como verdadeiras, as mercadorias não correspondem ao pedido, e os problemas de qualidade encontrados pelo cliente durante a instalação, o processo de colocação e uso são confirmados como problemas de qualidade do próprio produto, Se a entrega não estiver de acordo com os requisitos do contrato, por favor entre em contato com nossa empresa diretamente.