Cabos de alta tensão

Cabos de alta tensão pode ser dividido em cabos de alta tensão de núcleo de alumínio e cabos de núcleo de cobre de acordo com diferentes materiais. Faixa de nível de tensão: 6/64 kV, 48/66 kV, 66/120 kV, 127/220 KV e outra tensão ultra-alta. Devido às complexas condições ambientais e requisitos especiais em determinadas áreas, O uso de cabos de núcleo de cobre é mais confiável em termos de qualidade e segurança. De acordo com nossa experiência de produção, A seleção de especificações técnicas e a área transversal de cabos de alta tensão deve ser feita com referência ao ambiente circundante, o método de posicionamento correspondente e o desempenho do equipamento elétrico. Bem -vindo a Obtenha uma citação grátis.

Tipos de cabo de alta tensão

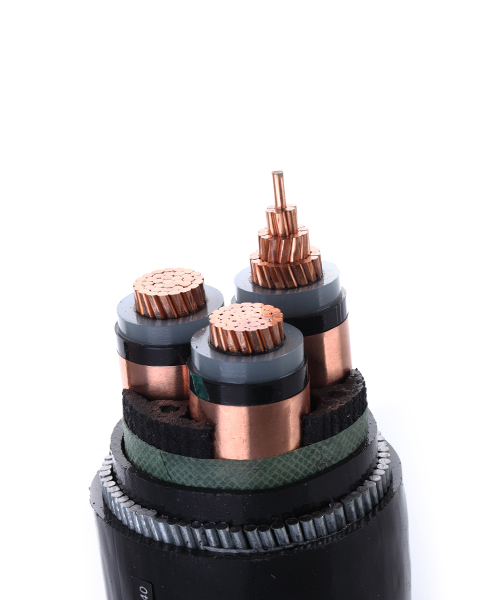

YJV22 10KV 35KV HIGH COLTAGE CABER CABO

Cabos de alta tensão YJV22 são usados para transmissão de energia e distribuição de sistemas de cabos de alta tensão com tensões nominais de 0,6/1kV, 1.8/3kv, 3.6/6kv, 6/10kv, 8.7/10kv, 8.7/15kv, 12/20kv, 21/35kv, 26/35kv.

1. XLPE isolado, Cabos de energia embalada de PVC (YJV, YJLV) são adequados para dentro de casa, túneis, tubos, e enterrado no solo (não está sujeito a força mecânica)

2. XLPE isolado, Fita de aço blindado Cabos de energia embalada de PVC (YJV22, YJLV22) são adequados para internos, túnel, penetração do tubo, e enterrado no solo

3. XLPE isolado, cabos de energia blindados de arame de aço blindados (YJV32, 42, Yjlv32, 42) são adequados para eixos, água, lugares com gota, e pode suportar forças externas.

O raio mínimo de curvatura do cabo

Item | Três -Core | |

Sem armadura | Blindado | |

Raio de curvatura mínima do cabo no curso da instalação. | 15D | 12D |

O raio mínimo de curvatura do cabo próximo à caixa de junção e terminal | 12D | 10D |

Observação: D é diâmetro externo do cabo | ||

Especificação de tamanho do cabo HV

Área de seção transversal(mm²) | Espessura isolada(milímetros) | Espessura do escudo de metal(milímetros) | Espessura da jaqueta(milímetros) | DE(milímetros) | Peso(kg/km) |

3×25 | 4.5 | 30×0.10 | 2.4 | 44.8 | 2251.6 |

3×35 | 4.5 | 40×0.10 | 2.5 | 47.2 | 2655.9 |

3×50 | 4.5 | 40×0.10 | 2.6 | 50.4 | 3217.3 |

3×70 | 4.5 | 40×0.10 | 2.7 | 54.0 | 3957.2 |

3×95 | 4.5 | 40×0.10 | 2.8 | 57.7 | 4884.7 |

3×120 | 4.5 | 40×0.10 | 2.9 | 60.9 | 5754.2 |

3×150 | 4.5 | 40×0.10 | 3.0 | 64.5 | 6788.0 |

3×185 | 4.5 | 40×0.10 | 3.1 | 68.2 | 7961.6 |

3×240 | 4.5 | 40×0.10 | 3.3 | 73.5 | 9801.3 |

3×300 | 4.5 | 40×0.10 | 3.4 | 78.3 | 11725.3 |

3×400 | 4.5 | 40×0.10 | 3.7 | 85.8 | 14799.2 |

Recursos da estrutura do produto:

1. Tem boa resistência de alta temperatura: O isolamento XLPE usa métodos químicos ou físicos para alterar a estrutura das moléculas de polietileno em uma estrutura de rede tridimensional. A estrutura de rede tridimensional tem boa resistência ao calor e pode ser usada em trabalhos de longo prazo a uma alta temperatura de 90 graus Celsius, a vida útil pode ser tão longa quanto 40 anos.

2. Bom desempenho de isolamento: O polietileno não apenas mantém o desempenho de isolamento do polietileno reticulado, mas também tem uma melhoria adicional na resistência ao isolamento.

3. Altas propriedades mecânicas: dureza, rigidez, resistência ao desgaste, e a resistência ao impacto foi melhorada

4. Resistência química: O próprio XLPE tem forte resistência ao ácido e álcalis e resistência ao óleo

5. Proteção Ambiental: Como os produtos da combustão de polietileno reticulados são água e dióxido de carbono, A poluição ambiental é baixa, e atende aos requisitos de segurança contra incêndio.

6. A temperatura nominal máxima do condutor do cabo é de 90 ° C, e a temperatura máxima durante o curto -circuito (a duração mais longa não excede 5s) não excede 250 ° C.

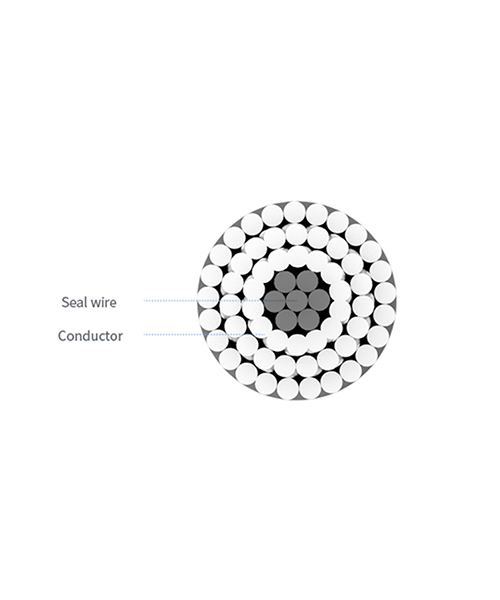

Linhas aéreas de alumínio de alta tensão

Condutor de alumínio, Cabo de teto reforçado com aço, é usado principalmente em linhas de transmissão de energia com alta tensão. Suas vantagens incluem alta resistência mecânica, boa condutividade elétrica, resistência à corrosão, volume da unidade de luz, ereção fácil, resistência de alta temperatura, estrutura simples, instalação conveniente, boa manutenção, e grande capacidade de transmissão. O cabo de aço de alta tensão de CAA consiste em um núcleo de aço sólido ou encalhado, cercado por fios de alumínio.

- Condutor: Alumínio

- Condutor de iluminação de rua: Condutor de alumínio em volta ou compactado

- Isolamento: LDPE / HDPE / XLPE / PVC

PADRÕES: GB/T12527/IEC60502/NFC 33-209/BS 7870/ANSI/ICEA S-76-474 AS/NZS 35601

Condutor de HV ACSR de acordo com GOST 839-80

| Seção | Parte de alumínio | Parte de aço | Min. Força de quebra | |||

|---|---|---|---|---|---|---|

| Número de fios | Nom. diâmetro do fio | Número de fios | Nom. diâmetro do fio | |||

| 1 | 16/2.7 | 6 | 1.85 milímetros. | 1 | 1.85 milímetros. | 6,220 N. |

| 2 | 25/4.2 | 6 | 2.30 milímetros. | 1 | 2.30 milímetros. | 9,296 N. |

| 3 | 35/6.2 | 6 | 2.80 milímetros. | 1 | 2.80 milímetros. | 13,524 N. |

| 4 | 50/8.0 | 6 | 3.20 milímetros. | 1 | 3.20 milímetros. | 17,112 N. |

| 5 | 70/11 | 6 | 3.80 milímetros. | 1 | 3.80 milímetros. | 24,130 N. |

| 6 | 70/72 | 18 | 2,20 milímetros. | 19 | 2.20 milímetros. | 96,862 N. |

| 7 | 95/16 | 6 | 4.50 milímetros. | 1 | 4.50 milímetros. | 33,369 N. |

| 8 | 120/19 | 26 | 2.40 milímetros. | 7 | 1.85 milímetros. | 41,521 N. |

| 9 | 120/27 | 30 | 2.20 milímetros. | 7 | 2.20 milímetros. | 49,465 N. |

| 10 | 150/19 | 24 | 2.80 milímetros. | 7 | 1.85 milímetros. | 46,307 N. |

| 11 | 150/24 | 26 | 2.70 milímetros. | 7 | 2.10 milímetros. | 52,279 N. |

| 12 | 150/34 | 30 | 2.50 milímetros. | 7 | 2.50 milímetros. | 62,643 N. |

| 13 | 185/24 | 24 | 3.15 milímetros. | 7 | 2.10 milímetros. | 58,075 N. |

| 14 | 185/29 | 26 | 2.98 milímetros. | 7 | 2.30 milímetros. | 62,055 N. |

| 15 | 185/43 | 30 | 2.80 milímetros. | 7 | 2.80 milímetros. | 77,767 N. |

| 16 | 205/27.0 | 24 | 3.30 milímetros. | 7 | 2.20 milímetros. | 63,740 N. |

| 17 | 240/32 | 24 | 3.60 milímetros. | 7 | 2.40 milímetros. | 75,050 N. |

| 18 | 240/39 | 26 | 3.40 milímetros. | 7 | 2.65 milímetros. | 80,895 N. |

| 19 | 240/56 | 30 | 3.20 milímetros. | 7 | 3.20 milímetros. | 98,253 N. |

| 20 | 300/39 | 24 | 4.00 milímetros. | 7 | 2.65 milímetros. | 90,574 N. |

| 21 | 300/48 | 26 | 3.80 milímetros. | 7 | 2.95 milímetros. | 100,623 N. |

| 22 | 300/204 | 54 | 2.65 milímetros. | 37 | 2.65 milímetros. | 284,579 N. |

| 23 | 330/43.0 | 54 | 2.80 milímetros. | 7 | 2.80 milímetros. | 103,784 N. |

| 24 | 400/18 | 42 | 3.40 milímetros. | 7 | 1.85 milímetros. | 85,600 N. |

| 25 | 400/51 | 54 | 3.05 milímetros. | 7 | 3.05 milímetros. | 120,481 N. |

| 26 | 400/64 | 26 | 4.34 milímetros. | 7 | 3.40 milímetros. | 129,183 N. |

| 27 | 400/93 | 30 | 4.15 milímetros. | 19 | 2.50 milímetros. | 173,715 N. |

| 28 | 500/27 | 76 | 2.84 milímetros. | 7 | 2.20 milímetros. | 112,188 N. |

| 29 | 500/64 | 54 | 3.40 milímetros. | 7 | 3.40 milímetros. | 148,257 N. |

| 30 | 600/72 | 54 | 3.70 milímetros. | 19 | 2.20 milímetros. | 183,835 N. |

APLICATIVO

O tipo desses cabos usa em linhas de distribuição de eletricidade, depositando -se em rios e vales onde existem criaturas geográficas especiais. O condutor de ACSR representa o componente mais importante de um linha de energia aérea Porque eles precisam garantir uma transmissão econômica e confiável e contribuir consideravelmente para os custos totais da linha.

Cabo HDPE HV 35kV a 110kV

Os cabos de alta tensão HDPE são normalmente usados em sistemas de transmissão e distribuição de energia de alta tensão e são adequados para instalação em dutos, trincheiras ou enterro direto no subsolo ou em edifícios. Esses cabos também são adequados para conectar parques eólicos e outras fontes de energia renovável para os sistemas de grade existentes.

Condutor: Cobre ou alumínio compactados ou segmentados com várias fita ou segmentados

Escudo de isolamento: Não metálico – camada semicondutora

Fita: Fita de água resistiva semi-condutiva

Bainha: Liderar

Bainha: Bainha HDPE (LSZH personalizado disponível)

PADRÕES: CEI 60840

Especificação técnica HDPE HV

Tamanho | Diâmetro do condutor | Espessura da tela do condutor | Isolamento Grossura | Diâmetro do núcleo nominal | Área de escudo de arame de cobre | Espessura da bainha HDPE | Diâmetro geral aproximado |

mm² | milímetros | milímetros | milímetros | milímetros | mm² | milímetros | milímetros |

150 | 14.4 | 1.2 | 18 | 56.2 | 95 | 4 | 70.6 |

185 | 15.6 | 1.2 | 18 | 57.4 | 95 | 4 | 71.8 |

240 | 18.3 | 1.2 | 18 | 60.1 | 95 | 4 | 74.5 |

300 | 20.6 | 1.2 | 18 | 62.4 | 95 | 4 | 76.8 |

400 | 22.9 | 1.2 | 18 | 64.7 | 95 | 4 | 79.1 |

500 | 26.4 | 1.2 | 18 | 68.2 | 95 | 4.5 | 83.6 |

630 | 29.8 | 1.2 | 18 | 71.6 | 95 | 4.5 | 87 |

800 | 36 | 1.2 | 18 | 77.8 | 95 | 4.5 | 93.2 |

1000 | 38.2 | 1.5 | 18 | 81.2 | 95 | 4.5 | 97.6 |

1200 | 42.8 | 1.5 | 18 | 85.8 | 95 | 4.5 | 102.2 |

1400 | 46.4 | 1.5 | 18 | 89.4 | 95 | 4.5 | 105.8 |

1600 | 48.9 | 1.5 | 18 | 91.9 | 95 | 4.5 | 108.3 |

Vantagens do produto:

Cabos Veri podem garantir que os cabos de alta tensão HDPE que produzimos atendam às especificações técnicas nacionais ou internacionais. Também podemos fornecer soluções precisas de colocação de cabos para projetos de energia de alta tensão com base na experiência de nossa equipe técnica, e todos os produtos podem ser fornecidos com Certificados de teste formais.

Colocação de cabos de alta tensão Veri

Inspeção antes da colocação do cabo: se o modelo e as especificações atendem aos requisitos, O isolamento deve ser bom, A aparência deve estar completa, E não deve haver traços de trauma.

Um comprimento de reposição deve ser reservado perto do terminal de cabo, e um comprimento de reposição deve ser reservado para o cabo diretamente enterrado na colocação em forma de onda. A distância entre cada ponto de apoio do cabo deve ser especificada no projeto. Quando não há regulamentos de design, não deve ser maior do que borracha cabos. Esses cabos de plástico são 1M horizontal, 2m vertical, e cabos suspensos em cabos de aço que são 0,75m horizontais. O raio de flexão do cabo não deve ser menor que 10 vezes o diâmetro externo do cabo (Cabo de alimentação isolado plástico blindado ou desarmado ou desarmado).

Ao colocar os cabos, Os cabos devem ser retirados da extremidade superior do carretel, e evite atrito e arrasto dos fios no suporte e no chão. Os cabos não devem ser cruzados ao deitar, Eles devem ser organizados, e corrigido, e os sinais devem ser instalados. Deve haver apostas firmes nos cantos dos cabos diretamente enterrados. Quando os cabos entram em trincheiras de cabo, túneis, edifícios, e tubos, As entradas e saídas devem ser fechadas. Grampos e acessórios para Cabos de núcleo único CA. não deve ter um circuito magnético fechado composto de ferro.

Transporte com serviço profissional

VERI Cable tem várias maneiras de proteger seus cabos, com embalagem de remessa resistente e profissional e seguro abrangente. Antes do envio, nosso cabos são embalados em bobinas de madeira e bobinas de caixa de papelão ondulado. Durante o transporte, para proteger as extremidades do cabo da umidade, selamos com fita autoadesiva BOPP e não higroscópica.

Se houver problemas de qualidade, como embalagens danificadas e danos na superfície do produto no local quando as mercadorias forem recebidas, se as mercadorias forem confirmadas como verdadeiras, as mercadorias não correspondem ao pedido, e os problemas de qualidade encontrados pelo cliente durante a instalação, o processo de colocação e uso são confirmados como problemas de qualidade do próprio produto, Se a entrega não estiver de acordo com os requisitos do contrato, por favor entre em contato com nossa empresa diretamente.