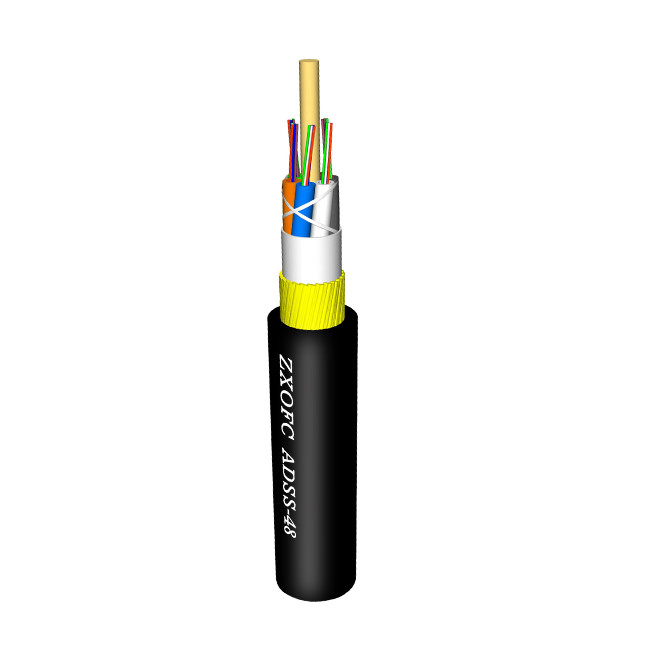

ADSS Fiber Optic Cable

VERI ADSS type of optical fiber is a communication cable consisting of glass or plastic fiber optic cores(two or more). ADSS fiber cable has excellent optical fiber transmission performance, optical cable mechanical properties, and environmental performance, and can be erected on the same pole with high-voltage power transmission lines. Each glass wire is capable of transmitting digital data modulated into light waves. They effectively send information encoded in a beam of light through a glass or plastic tube.

Our large catalog includes hard-to-find and high-demand items, like overhead bare conductors and electrical cables, rubber cables and more. Our high-quality cable product to a number of other standards such as IEC and other international standards. Our professional engineers can also design and develop optical fiber cable solutions to meet your application’s specific requirements.

Error: Contact form not found.

Different Types of ADSS Fiber Optic Cable

Telecommunication Use ADSS 24 Cores Single Mode Fiber Optic Cable

ADSS fiber optic cable is ideal for installation in distribution and transmission environments. As its name indicates, no support or messenger wire is required, so installation is achieved in a single pass, making ADSS an economical and simple means of achieving a fiber optic network.

Characteristics

- It can be installed without shutting off the power.

- Excellent AT performance. The maximum inductive at the operating point of the AT sheath can reach 25kV.

- Light weight and small diameter, reducing the load caused by ice and wind and the load on towers and back props.

- Large span lengths and the largest span is over 800m.

- Good performance of tensile strength and temperature.

- The design life span is over 30 године.

ADSS optical fiber cable is widely used in power lines and towers, and can also be used for communication lines in overhead laying environments such as lightning-prone areas and large-span environments. It is the most effective and convenient transmission method for power communication. Suitable for long-distance communication and interoffice communication. Available in AT and PE jackets for different voltage levels. Furthermore, we support customized multicore optical fiber cables, the number of cores that can be selected is 2 језгра, 6 језгра,12 језгра, 24 језгра, 48 језгра, и тако даље.

MT-ADSS Fiber Optic Cable Single Sheath 100m 24 Језгро 48 Језгро

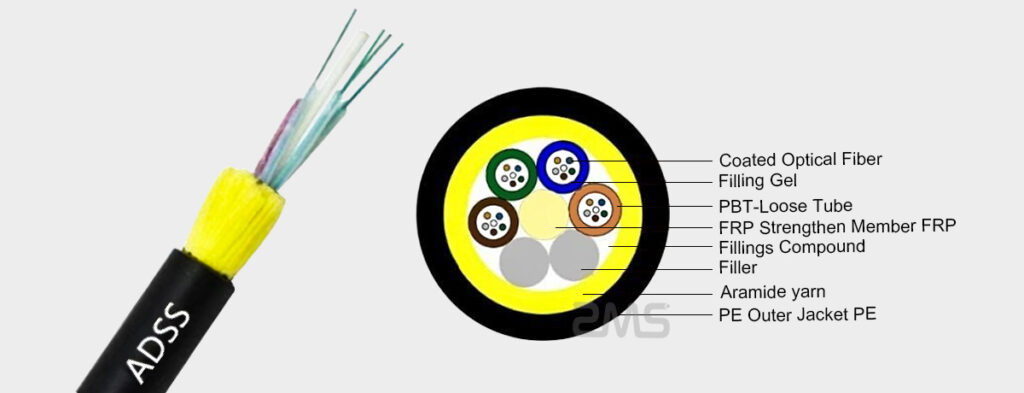

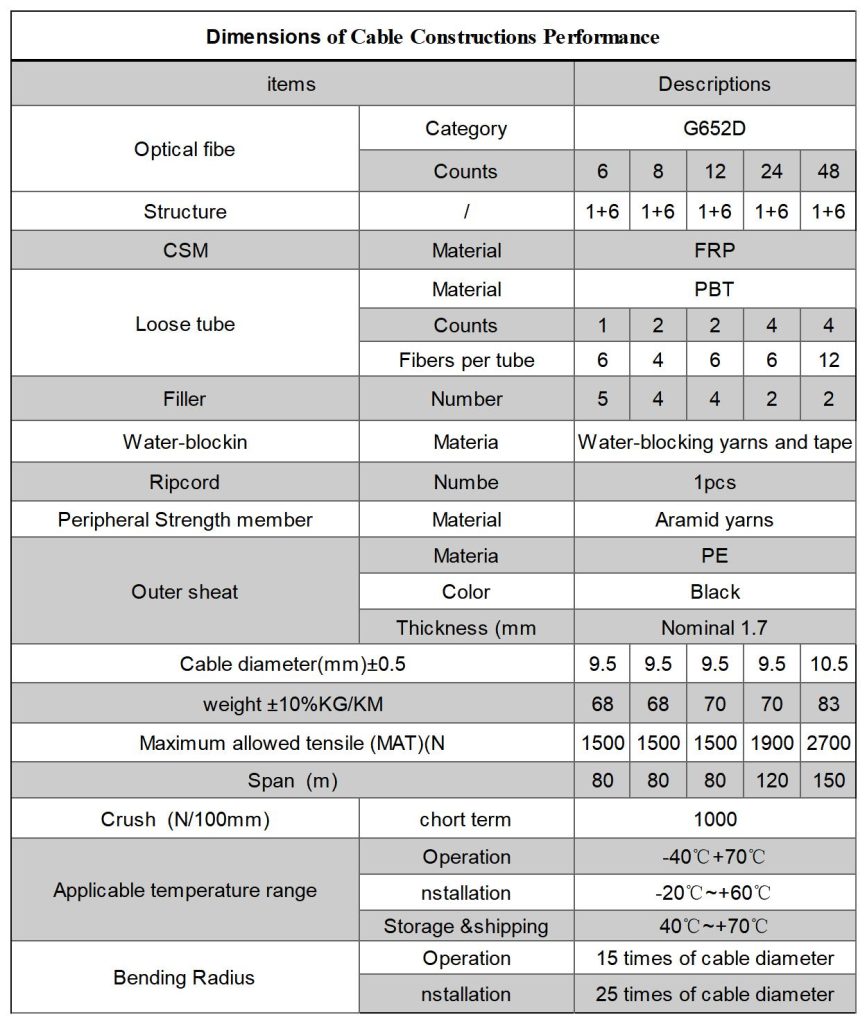

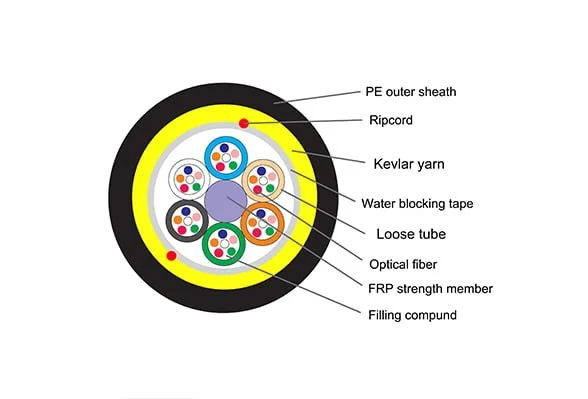

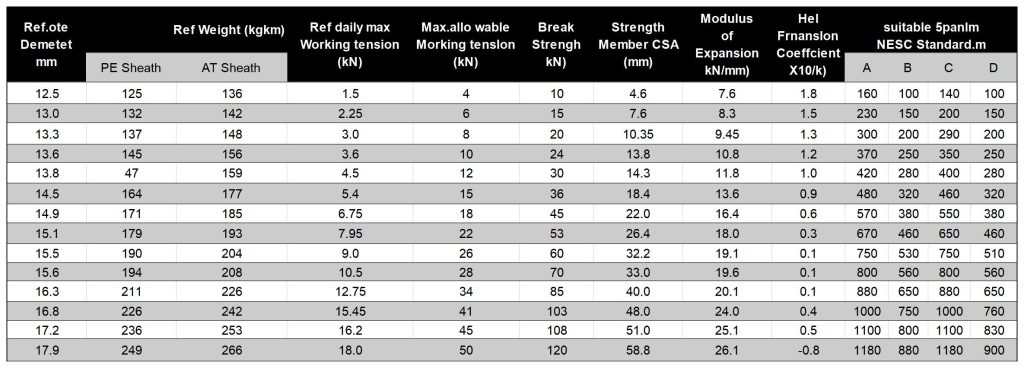

VERI ADSS cable is loose tube stranded. Fibers, 250μm, are positioned into a loose tube made of high-modulus plastics. The tubes are lined with a water-resistant filling compound. The tubes (and fillers) are stranded around an FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core. After the cable core is filled with the filling compound, it is covered with a thin PE (polyethylene) inner sheath. After a stranded layer of armed yarns is applied over the inner sheath as a strength member, the cable is completed with PE or AT(anti-tracking) outer sheath.

- It can be installed without shutting off the power.

- Excellent AT performance, the maximum inductive at the operating point of the AT sheath can reach 25kV.

- Lightweight and small diameter, reducing the load caused by ice and wind and the load on towers and back props.

- Large span lengths and the largest span is over 1000m.

Good performance of tensile strength and temperature.

Difference Between ADSS Fiber and OPGW Fiber

Structurally Different

The structural characteristics of ADSS fiber optic cable:

- The optical fiber in the casing for the loose sleeve structure.

- Cable core structure for layer stranding type

- The stranding method is SZ stranding

- The outer sheath has the function of anti-electrical corrosion

- The main load-bearing parts are aramid yarns

The structural characteristics of OPGW fiber optic cable:

- Fiber optic unit (Цев од нехрђајућег челика, aluminum clad stainless steel tube)

- Metal monofilament (aluminum clad steel, алуминијумска легура) peripheral reinforcement

Performance Difference

ADSS fiber optic cable performance characteristics:

- Aramid yarn peripheral reinforcement, bulletproof performance is good, in the distance of about 10 meters by the shooting fiber is not injured

- Metal-free, anti-electromagnetic interference, lightning, strong electromagnetic field resistance

- Excellent mechanical and environmental performance

- Lightweight, easy construction

- The use of existing towers, saving line construction costs

- Can be set up with electricity, reduce losses caused by power outages

- And power lines are independent of each other, easy maintenance

- Belongs to the self-supporting fiber optic cable, no need to hang line and other auxiliary hanging line

Performance characteristics of OPGW fiber optic cable:

- Excellent mechanical and environmental performance

- With the ground line has a good match, mechanical and electrical properties are almost identical

- To achieve fiber optic communications, while shunting short circuit current, conductive lightning current

The Method of Laying ADSS Fiber

ADSS fiber has a long history of successful installations in a variety of challenging climatic conditions.

This надземни кабл contains no metal parts and does not require support elements or ground connections for installation.

This improves safety and simplifies the installation of high-voltage and medium-voltage transmission line circuits that span lengths from a few hundred feet to several thousand feet.

VERI Cable’s enterprise cabling, also known as premise cabling, is most commonly used as a tight buffer solution for indoor network installations with stringent building code requirements, and for high performance applications where connectivity is an absolute necessity.

ВЕРИ Цабле is the right choice for your fiber optic cable needs. Specialty fiber optic cables from Veri Cable are the perfect solution for high-pressure and high temperature applications such as undersea and oil refineries. All Veri cable products are custom made to your specifications. With proven reliability, superior product, and industry knowledge.

Наше професионалне услуге

Потврда квалитета

Производи произведени од стране Вери Каблова у складу су са међународним стандардима као што су ГБ, Иец, Бс, НФЦ, Астм, Од, итд. Штавише, Наш технички тим може пружити услуге прилагођавања каблова за ваше потребе.

Праћење купаца

Вери нуди бесплатне професионалне услуге кабловске консултације, Услуге решења за пројекат за једно-заустављање, и брзе решења за доставу производа.

Професионални превоз

Вери каблови’ Почетни циљ је да се обезбеди брза и сигурна испорука производа, истовремено пружајући најбољу паковање и транспортна решења за смањење купаца’ Транспорт кошта увелике.

Кабловска амбалажа

Вери кабловско паковање се испоручује у дрвеним ролама, Слободне кутије, и завојнице. Крајеви су запечаћени са бопп самољепљивом траком и нехигроскопским заптивним поклопцима за заштиту кабла завршава се од влаге. Потребни логотип можемо да одштампамо на спољној страни бубњева водоотпорним материјалом према захтеву купца.