HV XLPE Insulated Cable

VERI Cables is a global supplier of a wide range of HV XLPE insulated cable types in stock. We will select the right HV XLPE cables for your project such as power supply, providing a cost-effective and safe maintenance solution.

- Product qualification ISO9001, ISO 14001, GB/T 28001, итд.

- Including producing ultra-high voltage cables with rated voltages of up to 500kv.

- Its insulation material and armor construction can withstand different harsh environments, including humid, acidic, and corrosive environments.

Hot Models

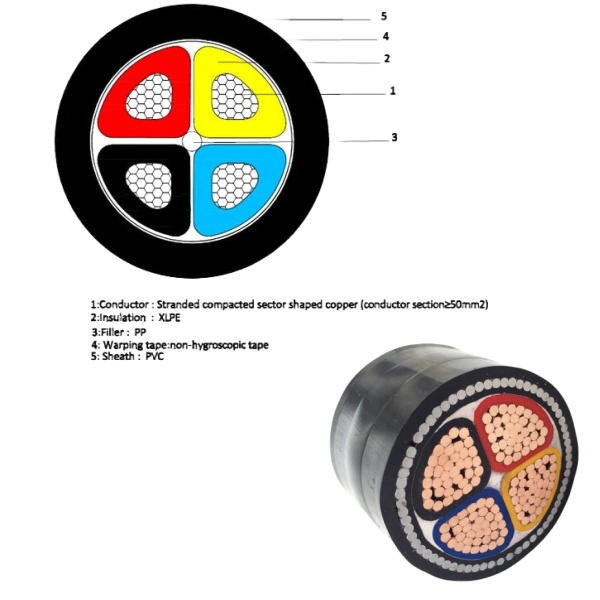

4 Cores HV XLPE Insulated Cable

Проводник: Smooth round, compacted stranded copper or aluminum conductor.

Bonding Filler: Polypropylene laminate with overlap tape

4 core wire color identification: red, yellow, blue, black

Armoring: Galvanized steel wire over XLPE liner

Стандардни: Иец 602282

These 4-core high-voltage XLPE cables are best suited for pipeline installations, direct underground burials, Снаге за напајање, and other industrial installations where mechanical damage is risky.

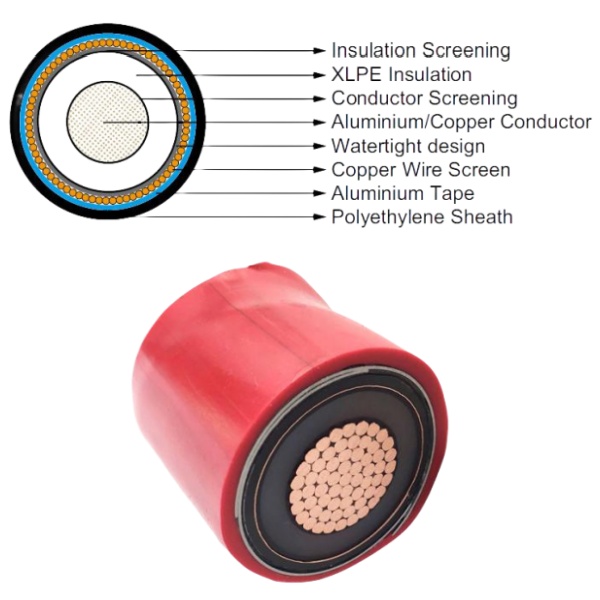

HV XLPE Aluminum Shield Underground Cables

Свадби, Наношење, and armored XLPE cables can also be manufactured

Reliable, low cost, easy maintenance, after-sales guarantee

Suitable for buried cables in distribution networks

Conforms to IEC60502.2-2008 IEC 60840-2011 IEC60228 and other quality standards.

Our high voltage underground cables have many advantages over other types of HV XLPE insulated single core cables. Not only do they last longer, but they are also resistant to different harsh environments such as storms or direct sunlight.

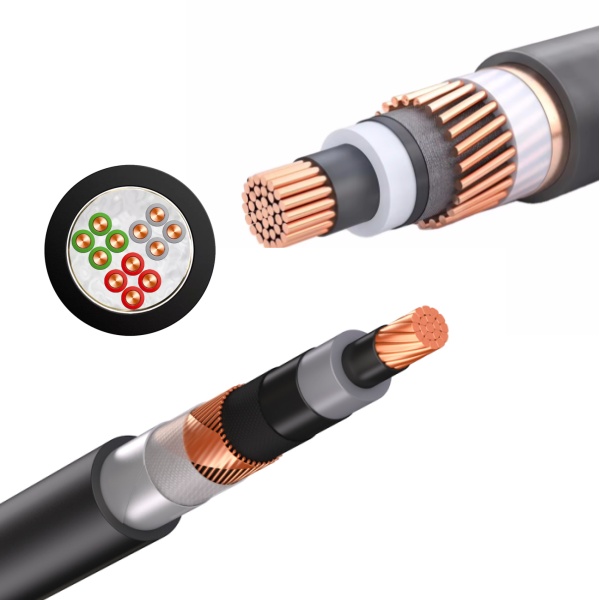

HV 2XS(Ф)2И, A2XS(Ф)2Y 110kV Electric Cable

Проводник: Класа 2 copper or aluminum conductor, compacted or segment strand Milliken

Екран за проводник: Extruded semi-conductive XLPE

Изолација: КСЛПЕ

Сепаратор: Water swellable semi-conductive tape

Screen: Copper wire screen, with a counter helix of copper tape

Стандарди: Иец 60840, HRN HD 632, IEC/EN 60228

HV 2XS(Фл)2Y HDPE 76/132kV XLPE Cable

Проводник: Copper conductor (optional watertightness – WTC)

Екран за проводник: Semi-conductive screen extruded on the phase conductor

Изолација: КСЛПЕ

Екран за изолацију: Semi-conductive screen extruded on insulation

Wrapping: Semi-conductive water swelling tape

Tape: Longitudinally applied aluminium tape coated with PE copolymer

Омотач: ХДПЕ (High Density Polyethylene)

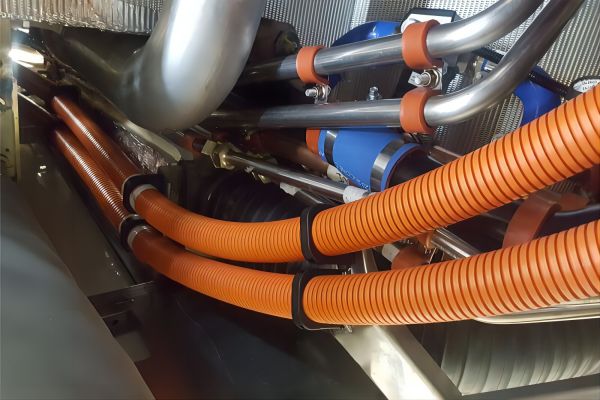

XLPE High Voltage Cable Application

110kv High Voltage XLPE Insulated Power Cable for distribution networks; also for connection to generation units and plant and process connection. For installation on the ground, in water outdoors, indoors, and in cable ducts for power stations, industry, and distribution networks. The water-blocking tape avoids water propagation inside the cable.

In some specific applications, XLPE insulation will be better suited than PVC for voltage ranges from low voltage to ultra-high voltage.

If you have order requirements, please feel free to contact us!

About VERI Cable After-Sales Service

First, Product Quality Commitment:

- There are quality records and testing data for the manufacture and testing of all cable products.

- For the inspection of product performance, we sincerely invite users to inspect the whole process and performance of the product in person. After the product is confirmed to be qualified, it will be packaged and shipped.

Second, the product price commitment:

- In order to ensure the high reliability of the product, the material selection of the system is made of domestic or high-quality products.

- Under the same competitive conditions, our company will sincerely provide you at an affordable price without reducing the technical performance of the product or changing the product components.

- Delivery time commitment:

Third, Product delivery time:

As far as possible according to user requirements, if there are special requirements that need to be completed in advance, our company can specially organize production and installation, and strive to meet user needs.

Fourth, after-sales service commitment:

- Service tenet: fast, decisive, accurate, thoughtful and thorough.

- Service objectives: service quality to win customer satisfaction.

- Service efficiency: If the equipment fails within the warranty period or outside the warranty period, after the supplier is notified, the maintenance personnel can reach the site and start maintenance within 24 сати.

- Service principle: The warranty period of cable products is twelve months. During the warranty period, the supplier will repair and replace the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, the provided accessories will only charge the cost the cost of equipment damage caused by human factors of the buyer, and the accessories repaired or provided by the supplier are calculated at cost.