AAC AAAC ACSR

VERI Cable, according to different uses, produces a variety of overhead cables. Including AAC, AAAC, ACSR, ABC okun –aerial bundled cable, ati bẹbẹ lọ. Our range of overhead lines generally contains aluminum conductors or aluminum alloy conductors to meet all customer needs. We specialize in providing excellent overhead lines for transmission, distribution, and power network industries. And other cable products such as voltage cables, submarine kebulu, fiber cables, special cables, ati bẹbẹ lọ. So please contact us with your requirements. Also, we will reply to you the detailed information that you want.

Types of VERI AAC AAAC ACSR

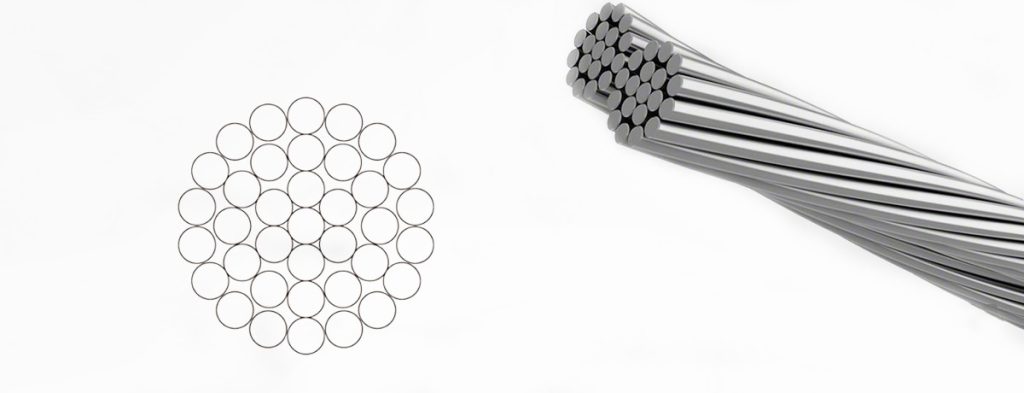

All Aluminum Conductor—AAC

Aluminum Alloy Adarí is the main component of the overhead power line. Its function is to transmit current and electric power. These bare conductors are suitable for low, medium, and high-voltage overhead lines. AAC is widely used in urban areas, where the span is usually short. But the conductivity requirements are high.

Awọn ajohunše&Awọn itọkasi:ASTM—B 230, ASTM—B 231, DIN48201, BS215 (Or producing by the standard of the customer’s country)

- Phase conductors: round stood or compacted 1350-H19 aluminum or copper conductor, AAAC, ACSR

- Neutral or messenger conductor: round stood or compacted 6201 aluminum alloy or AAC, ACSR

- Street lighting conductor: round stood or compacted aluminum conductor

- Idabobo: LDPE, HDPE, XLPE, PVC

Manufacturing Standards

Conductor Size | Code Words | Class | Required Construction | Mass | Ti won won Agbara | |||||

Cmils or AWG | mm² | Rara. of Wires | Diameter of Wire | Per 1000ft, lb | Per km, kg | kips | kn | |||

In. | mm | |||||||||

3500000 | 1773 | Bluebonnet | A | 127 | 0.1660 | 4.22 | 3345 | 4977 | 58.7 | 261 |

3000000 | 1520 | Trillium | A | 127 | 0.1537 | 3.90 | 2840 | 4226 | 50.3 | 223 |

2750000 | 1393 | Bitterroot | A | 91 | 0.1738 | 4.42 | 2602 | 3872 | 46.1 | 205 |

2500000 | 1267 | Lupine | A | 91 | 0.1657 | 4.21 | 2365 | 3519 | 41.9 | 186 |

2250000 | 1140 | Sagebrush | A | 91 | 0.1572 | 3.99 | 2128 | 3166 | 37.7 | 167 |

2000000 | 1013 | Cowslip | A | 91 | 0.1482 | 3.77 | 1873 | 2787 | 34.2 | 153 |

1750000 | 886.7 | Jessamine | AA | 61 | 0.1694 | 4.30 | 1641 | 2442 | 29.7 | 132 |

1590000 | 805.7 | Coreopsis | AA | 61 | 0.1614 | 4.10 | 1489 | 2216 | 27.0 | 120 |

1510500 | 765.4 | Gladiolus | AA,A | 61 | 0.1574 | 4.00 | 1417 | 2108 | 25.6 | 114 |

1431000 | 725.1 | Carnation | AA,A | 61 | 0.1532 | 3.89 | 1342 | 1997 | 24.3 | 108 |

1351000 | 694.8 | Columbine | AA,A | 61 | 0.1488 | 3.78 | 1266 | 1884 | 23.4 | 104 |

APPLICATION

All aluminum conductors belong to bare conductors, which mainly play the role of transmitting electrical energy. Based on different voltages, the wire cross-sectional area is also different. AAC cable is commonly used for general distribution lines with a small force and small span. But it is not allowed to contact with trees.

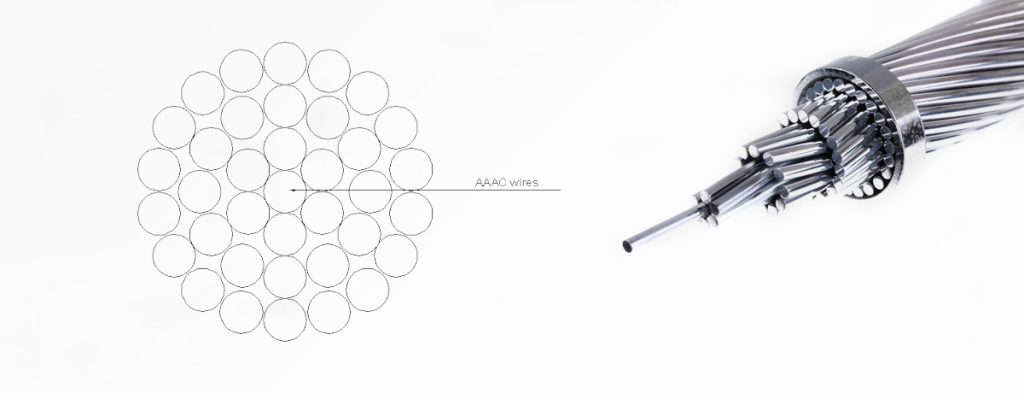

All Aluminum Alloy Conductor—AAAC

Adarí: Hard-Drawn 1350-H19 Aluminum Wires, Minimum Purity 99.45%.

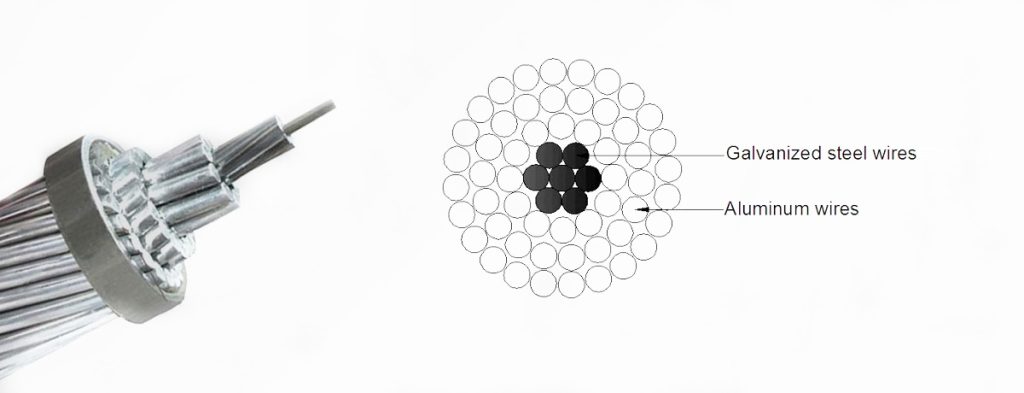

Reinforcement: Galvanized Steel Wires (Zinc-Coated)

Construction (Aluminum/Steel): 6/1, 7/1, 8/1, 12/7, 16/19, 24/7, 26/7, 30/7, 30/19, 36/1, 45/7, 54/7, 54/19, 72/7, 76/19, 84/19

Cross-Sectional Area: 6~4/0 awg, 80~2312 mcm (80~211.3 mcm for Standard High-Strength Conductor).

Galvanization: Class A, B or C

Grease Corrosion Protection: Available upon Request

Specifications

AAAC bare conductor meets the following ASTM specifications :

B-398 Aluminum Alloy 6201-T81 Wire for Electrical Purposes

B-399 Concentric-Lay-Stranded 6201-T81 Aluminum Alloy Conductors.

The Part of AAAC-ASTM-B399 Technical Data:

Stranding | Diameter of conductor | Linear mass | Rated strength | D.C. resistance at 20℃ |

No./mm | mm | Kg/km | kgf | Ω/km |

6 | 7/1.55 | 4.65 | 36.44 | 422 |

7/1.68 | 5.04 | 42.7 | 502 | |

4 | 7/1.96 | 5.89 | 57.89 | 685 |

48.69(4) | 7/2.12 | 6.35 | 67.56 | 799 |

2 | 7/2.47 | 7.42 | 92.14 | 1091 |

77.47(2) | 7/2.67 | 8.02 | 107.50 | 1275 |

1/0 | 7/3.12 | 9.35 | 146.50 | 1733 |

123.3(1/0) | 7/3. 37 | 10.11 | 171.00 | 2019 |

2/0 | 7/3.50 | 10.52 | 184.70 | 2090 |

155.4(2/0) | 7/3.78 | 11.35 | 215.16 | 2447 |

3/0 | 7/3.93 | 11.79 | 232.70 | 2641 |

195.7 (3/0) | 7/4.25 | 12.75 | 271.50 | 3079 |

4/0 | 7/4.42 | 13.26 | 293.70 | 3334 |

246.9 (4/0) | 7/4.77 | 14.30 | 342.60 | 3885 |

Ohun elo:

Used as bare overhead conductor for primary and secondary distribution. The AAAC conductor is designed to get a better strength-to-weight ratio and offer improved electrical properties, excellent sag-tension characteristics, and superior corrosion resistance when compared with ACSR. As compared to a conventional ACSR conductor, the lighter weight, comparable strength & current carrying capacity, lower electrical losses, and superior corrosion resistance have given AAAC a wide acceptance in the distribution and medium & high voltage transmission lines.

Aluminum Conductor Steel Reinforced—ACSR

ACSR conductor has the advantages of simple structure, convenient erection and maintenance, low line cost, and large transmission capacity. And they are convenient for laying across special geographical conditions. Such as rivers and valleys, good electrical conductivity, and sufficient mechanical.

Design

1 Aluminum conductor with increased breaking load, round stranded compressed (RM)

2 Core insulation (XPLE black, UV-resistant, not flame retardant); 2 up to 4 cores of the equal cross-section are stranded together in left-hand lay, additionally 1 tabi 2 cores of the reduced cross-section can be co-stranded.

Awọn ajohunše&Awọn itọkasi:ASTM—B 230, ASTM—B 231, DIN48201, BS215 (Or producing by the standard of the customer’s country)

ACSR Technical Characteristics / U.S.A Sizes – ASTM B232

Area | Stranding and diameter | Approximate overall diameter | ||||

Aluminum | Steel | Total | Aluminum | Steel | ||

AWG or MCM | mm2 | mm2 | mm2 | mm | mm | mm |

8 | 8.34 | 1.39 | 9.73 | 6/1.33 | 1/1.33 | 3.99 |

6 | 13.29 | 2.19 | 15.48 | 6/1.68 | 1/1.68 | 5.04 |

4 | 21.16 | 3.55 | 24.71 | 6/2.12 | 1/2.12 | 6.36 |

4 | 21.16 | 5.35 | 26.50 | 7/1.96 | 1/2.61 | 6.53 |

3 | 26.69 | 4.45 | 31.14 | 6/2.38 | 1/2.38 | 7.14 |

2 | 33.61 | 5.61 | 39.22 | 6/2.67 | 1/2.67 | 8.01 |

2 | 33.61 | 8.52 | 42.13 | 7/2.47 | 1/3.30 | 8.24 |

1 | 42.39 | 7.10 | 49.49 | 6/3.00 | 1/3.00 | 9.00 |

0 | 53.48 | 8.90 | 62.38 | 6/3.37 | 1/3.37 | 10.11 |

2/0 | 67.42 | 11.23 | 78.65 | 6/3.78 | 1/3.78 | 11.34 |

3/0 | 85.03 | 14.19 | 99.22 | 6/4.25 | 1/4.25 | 12.75 |

4/0 | 107.23 | 17.87 | 125.10 | 6/4.77 | 1/4.77 | 14.31 |

Application of ACSR

1. The higher-strength ACSR conductors are widely used in power transmission lines with various voltage levels.

2. The higher-strength ACSR conductors are commonly used for river crossings, overhead earth wires, and installations involving extra-long spans.

3. The higher-strength ACSR conductors are also suitable for laying across rivers and valleys where special geographical features exist.

Excellent Service of VERI Cable

Export Iriri

Bi awọn kan ọjọgbọn USB olupese, Awọn ọja okun wa ti okeere si ọpọlọpọ awọn orilẹ-ede ni igba atijọ 30 odun, pẹlu USA, Canada, Spain, UK, Jẹmánì, France, Russia, Greece, Saudi Arebia, ati be be lo. Ni awọn orilẹ-ede wọnyi, Awọn ọja okun wa jẹ olokiki pupọ pẹlu awọn alabara. Ati gbogbo odun, nitori ti wa ti o dara didara ati iṣẹ, a yoo gba esi to dara pupọ lati ọdọ awọn alabara wa.

Adani USB Service

Ibiti o wa ti awọn iṣẹ aṣa pẹlu apẹrẹ, iwọn, ati dada awọ. Ọpọlọpọ awọn awọ olokiki tun wa fun ọ lati yan. A tun ṣe amọja ni fifin-ọṣọ, fun apere, a le ṣe Polyethylene aṣa (PE) ati Polyurethane (PUR) gẹgẹ bi awọn ibeere rẹ. A le pese awọn ojutu ti o da lori awọn imọran rẹ. Jọwọ kan si wa lati fun wa ni ero rẹ.

Awọn ajohunše Ayẹwo Didara to muna

Veri Cable offers a wide variety of power cables based on trends and personal preferences. Ati pe a pese gbogbo iru awọn kebulu agbara, ju lọ 100 jara. Lẹhinna, lati rii daju awọn didara ti awọn kebulu, a ta ku lori idanwo awọn ọja wa lẹẹkan ni igba diẹ.