WÁRÒ GAS EPO & CABLE

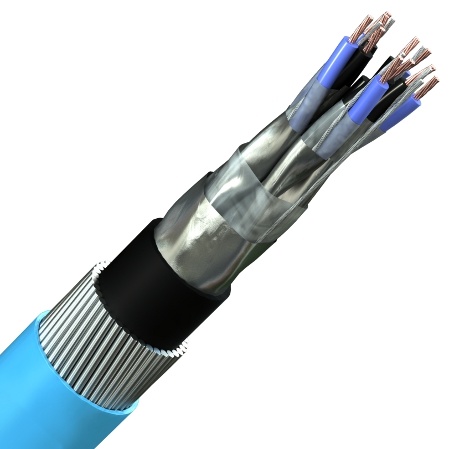

In areas where oil and gas capacity is well developed, how it is exploited is a crucial step.VERI Cables produces specialized cables for oil and gas, whether for mobile offshore drilling rigs, floating production storage, and offloading units, or land-based operations, which are safe from exposure to a wide range of chemicals, oils, acids, and hydrocarbon-containing slurries, as well as from high-intensity UV rays, salt-water immersion, and mechanical and thermal stresses. The cables offered by us are made of high-quality materials.

The special cables for oil and gas we offer are made of specialized LSZH insulation, which focuses on environmental safety, such as low smoke and halogen free instrumentation cables. In terms of standards, it complies with multiple British BS and international IEC standards. Construction includes mica tape fire barriers, lead (and lead equivalents) jackets, and blue outer jackets for intrinsically safe circuits.

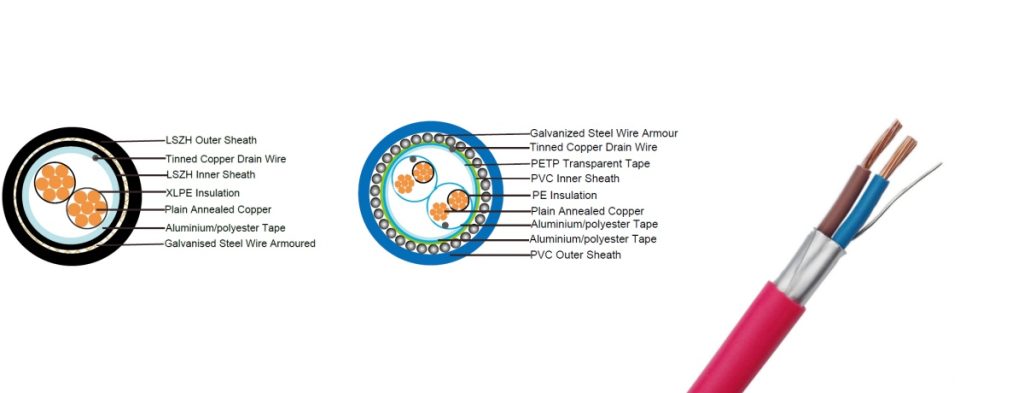

BS EN 50288-7 - LSZH Cable

APPLICATION

These cables are designed to connect electrical instrument circuits and provide communication services in and around process plants (e.g. petrochemical industry etc.). Suitable for direct burial applications. For installations where fire, smoke emissions, and toxic fumes create a potential risk to life and equipment.

CHARACTERISTICS

Voltage Rating: 300V

Awọn iwọn otutu ti nṣiṣẹ

Fixed: -40°C to +80°C

Flexed: 0°C to +50°C

Minimum Bending Radius: 12 x overall diameter

Awọn ajohunše

EN 50288-7, EN 50288-1, EN 60228

Flame Retardant to: IEC/EN 60332-1-2, IEC/EN 60332-3-24

Low Smoke Halogen Free to IEC/EN 60754-1/2, IEC/EN 61034-2

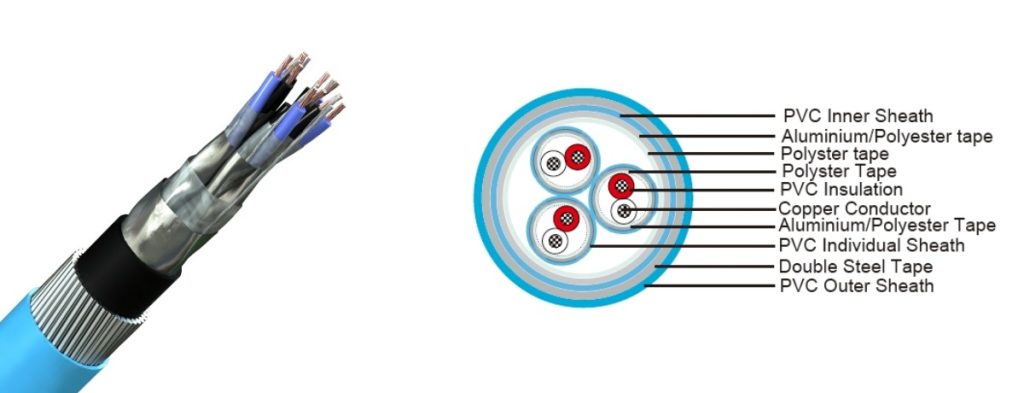

NF M87 Screened Unarmored PVC Cable

APPLICATION

These cables are designed for safe use in petroleum and petrochemical units particularly for the transmission of AC or DC analogue signals. Suitable for aliphatic hydrocarbons resistance applications.

CHARACTERISTICS

Voltage Rating (Uo/U): 300/500V

Installation Temperature Range

Installation: +5°C to +50ºC

Operating: +90ºC

Awọn ajohunše

NF M 87 – 202, UTE C 32-014, EN 60331-21

Flame Retardant according to: IEC/EN 60332-1-2, IEC/EN 60332-3-24

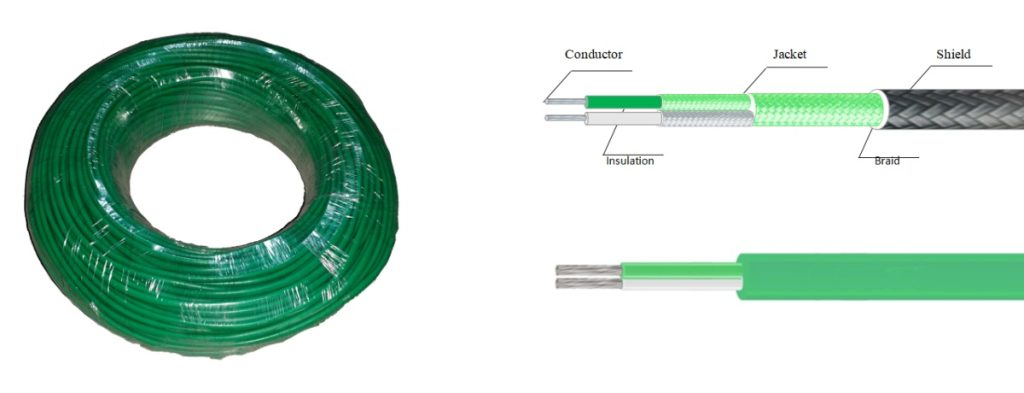

Thermocouple KX Screen 250V

APPLICATION

The thermocouple extension cable is a thermocouple cable that is identified by the letter X (e.g. for type K cable KX). Extension grade wire only extends a thermocouple signal from a probe back to the instrument reading the signal. These cables are used with thermocouples for temperature measurements where hydrocarbon may be present.

CHARACTERISTICS

Voltage Rating: 250V

Test Voltage

Dielectric test voltage: 1.0 KVac/1’ (core/core)

Dielectric test voltage: 1.0 KVac/1’ (core/screen)

Temperature Rating: -20 to +60°C

Minimum Bending Radius Flexing: 8 x overall diameter

Awọn ajohunše

IEC 60584-3, NF C 42-324, NFC 32070 C2, IEC 60332-1-2

VERI Cables can produce a full line of thermocouple cables, such as the hot-selling type K-series and type J-series, so please feel free to contact us.

More Types of Cables Used in Oil and Gas Industry

- XLPE/EPR/PVC/PE/OS Instrumentation cable

- XLPE/EPR/PVC/PE Individual & Overall Shield lnstrumentation Cable

- Continuous FlexIible Control Cable Bare Copper Wire

- LV 1000V E170315 Flexible Shielded Control Cable

- BS5308 Type 2 CAM SWA Armored Silicone LSZH Cable

- BS5308 Type 3 ICAM Lead PE SWA PVC XLPE Cable

- Providing Customized Services

Advantages of VERI in the Oil & Gas Industry

VERI’s greatest strengths are its confidence in the cables it produces, including international testing, quality cable materials and competitive pricing. We have been involved in many oil projects internationally and have also worked with oil and gas companies in the UAE, South Africa, Zambia, and other countries, supplying them with specialized types of cables, including customized ones.

The cables we manufacture are ideally suited for oil and gas projects in drilling, refining, pumping, and other operations where cable reliability and safety are critical.VERI cables for the oil industry are the first choice. Its high quality smoke and halogen free insulation ensures safe operation in the harshest fire environments and is resistant to acids, corrosion, ati water resistance.

How to Choose the Right Oil & Gas Cable?

/ | Harsh | Harsher | Harshest |

Description | Closed industrial environments, normal temperature, no visible corrosion | The working environment is exposed to the outdoors and contains chemical corrosive substances. | Extremely harsh outdoor environments or extreme conditions with explosive sources or strongly corrosive chemicals. |

Application Example | Natural Gas Compressor Station: Indoor heated environments where temperature extremes can occur and are unattended, making on-site maintenance or repairs expensive. | Petrochemical Processing Sites: Indoors or outdoors, exposed to high levels of UV radiation, requiring exposure to petroleum or other harsh chemicals. | Offshore fixed or mobile gas and oil platforms / onshore drilling rigs/pump jacks: These locations have extreme temperatures and high levels of UV radiation, and the cables are exposed to rain and seawater and require marine approvals such as ABS or DNV. |

Suitable Cable Sheath | 1. General Purpose: PVC Thermoplastic (TP) Jacket: suitable for most environments and applications. 2. Economical: LSZH (TP) Jacket: This jacket material emits only limited smoke in the event of a fire and contains no toxic halogens. | TPE (TP) Material Sleeve: Can be bent repeatedly, resistant to oil, welding spatter, and low temperature, and can be directly buried in the ground. CPE (TP) Jacket: oil-resistant, ultra-low temperature resistant, mainly made of chlorinated polyethylene. | XLPE LSZH (TP) Jacket: The XLPE cross-linking process is used to make the material more resistant to high temperatures. FEP (TP) Jacket: very resistant to high temperatures and weld splatter. Steel or Aluminum Armor Layer: Armoring is an added layer of external protection for harsh environments. It enhances the robustness of many types of cables and provides maximum mechanical protection. |

Please feel free to contact us for any questions and order requirements.

The Cable Accessories You Need

Our Professional Services

Quality Certification

The products manufactured by VERI Cables comply with international standards such as GB, IEC, BS, NFC, ASTM, DIN, ati be be lo. Moreover, our technical team can provide cable customization services for your needs.

Customer Tracking

VERI provides free professional cable consulting services, one-stop project solution services, and fast product delivery solutions.

Professional Transportation

VERI Cables’ initial goal is to ensure fast and safe delivery of products while also providing the best packaging and transportation solutions to reduce customers’ transportation costs greatly.

Cable Packaging

VERI cable packaging is supplied in wooden reels, corrugated boxes, and coils. The ends are sealed with BOPP self-adhesive tape and non-hygroscopic sealing caps to protect the cable ends from moisture. We can print the required logo on the outside of the drums with waterproof material as per the customer’s requirement.