Verschiedene Arten von Drähten und Kabeln haben unterschiedliche Manteldicken, wie Gummikabel. Sie werden hauptsächlich an verschleißfesten und kältebeständigen Orten eingesetzt. Und die Isolierhülle ist dicker. Allgemein, desto höher der Spannungspegel, desto dicker die Hülle. Und die Dicke von Kabeln, die für elektrische Niederspannungsgeräte verwendet werden, berücksichtigt im Allgemeinen nicht hauptsächlich die elektrischen Eigenschaften, sondern hauptsächlich mechanische Eigenschaften.

Gummikabel werden häufig in verschiedenen elektrischen Geräten verwendet und können unter Umgebungsbedingungen im Innen- und Außenbereich verwendet werden.

Nutzen Sie die Eigenschaften des Gummikabels

Das Gummimantelkabel ist vor allem für den Anschluss leichter mobiler Geräte geeignet (Haushaltsgeräte, Elektrowerkzeuge, usw.), Instrumentierung, und Power-Beleuchtung. Die Arbeitsspannung liegt unter AC 750 V, und die meisten von ihnen sind AC 300V. Weil das Produkt bewegt werden muss, gebogen, verdreht, etc. Und der Draht muss weich sein, und stabil in der Struktur. Dann weist es eine gewisse Verschleißfestigkeit auf. Das kunststoffummantelte Kabel kann direkt im Erdreich verlegt werden.

Beim Anschluss an die Stromversorgung von Elektroheizgeräten, Je nach Bedarf sollten geflochtene, mit Gummi isolierte Kabel oder mit Gummi isolierte Kabel verwendet werden.

Strukturmerkmale von Gummikabeln

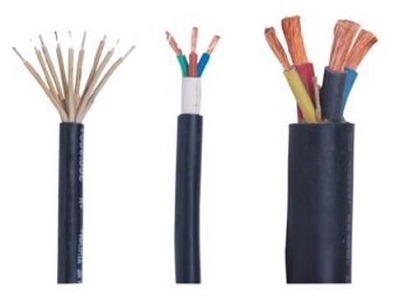

Der leitende Drahtkern besteht aus einem Kupferkern, und die Struktur ist weich, Dabei handelt es sich um einen flexiblen Drahtleiter, der durch Verdrillen mehrerer einzelner Drahtbündel gebildet wird. Dämmstoffe verwenden im Allgemeinen natürlichen Styrol-Butadien-Kautschuk, Polyvinylchlorid, oder weichem Polyethylen-Kunststoff. Der Kabelabstand ist um ein Vielfaches kleiner.

Die äußere Schutzschicht des mit Gummi ummantelten Kabels ist mit Baumwollgarn gewebt, um eine Überhitzung und Verbrühungen der Isolierschicht zu vermeiden. Um die Verwendung zu erleichtern und den Produktionsprozess zu vereinfachen, Die ausgewogene Drei-Kern-Struktur wird übernommen, Dies kann Produktionszeit sparen und die Produktionseffizienz verbessern.

Die Zukunft des Gummikabels

Anders als herkömmliche Produkte, Die Besonderheit von Gummimantelkabeln besteht darin, dass unterschiedliche Produkte entsprechend unterschiedlicher Kundenanforderungen und Anwendungsumgebungen entwickelt werden müssen.

Gummikabel, mit Gummi-Isoliermaterial als Isolierschicht und Mantelschicht, ist einfacher zu recyceln, und erzeugt beim Verbrennen keine giftigen Gase. Es steht im Einklang mit dem aktuellen Landeskonzept der Umweltkabel und ist die zukünftige Weiterentwicklung der Kabel- und Kabeltechnik Kabelindustrie.