Subsea Electrical Cables

Subsea Electrical Cables are electrical wires wrapped in insulating and waterproof materials and laid underwater on the seabed and in rivers for the transmission of electricity or communications. Submarine cables are used for offshore wind power, ikpo okwu igwu mmiri n'ụsọ osimiri, island grid interconnections, land island interconnections and other offshore projects to provide communication and power transmission.

VERI Submarine Power Cables has been researching the production of subsea electric cables for many years. Whether it is from environmental exploration of the seabed, marine physical surveys or case studies of large projects around the world. We also utilize advanced cable design, manufacturing and installation methods. Our subsea electric cables are guaranteed for excellent water resistance and longevity.

Subsea Electrical Cable Products Model

XLPE Insulated Submarine Cable

XLPE insulated subsea power cable has several advantages over paper-insulated and PVC-insulated cable. It has high electric strength, mechanical strength, high-aging resistance, environmental metal stress resisting anti-chemical cross, and it is a simple construction, using convenient and higher operating of long term temperature. It can be laid with no drop restriction.

Ngwa: These subsea power cables are suitable for fixed installations in the offshore range, such as distribution networks or industrial installations. Such as plant engineering, industrial machinery, heating and air conditioning systems, ọdụ ọkụ, wdg.

Rated Voltage: | 6/10kV, 6.35/11kV (12kV), 8.7/15kV, 12/20kV, 18/30kV,19/33kV |

Core Number: | Single Core or Three Core (1C or 3C) |

Available Dimensions: | 25mm2, 35mm2, 50mm2, 70mm2, 95mm2, 120mm2, 150mm2, 185mm2, 240mm2, 300mm2, 400mm2, 500mm2, 630mm2. |

Models | N2XSY, N2XSEY, NA2XSY, NA2XSEY, N2XSRY, NA2XSRY, N2XSEBY, N2XSEYBY, NA2XSEBY, N2XSERY, NA2XSERY, N2XSEYRGbY, NA2XSEYRGbY, YJV, YJLV, YJSV, YJLSV |

Onye nduzi: | Stranded round compacted copper or aluminum conductor (Ku / Al ), copper wire annealed. |

Conductor Screen: | Semi-conducting material |

Mkpuchi: | XLPE (Cross-Linked Polyethylene) |

Insulation Screen: | Semi-conducting material |

Metallic Screen: | Copper tape screen or copper wire screen (CTS / CWS ) |

Filler: | PP rope |

Nkewa: | Binding tape |

Ihe ndina: | PVC (Polyvinyl Chloride) |

Armouring: | Single Core: No Multi-core: No |

Sheath: | PVC (Polyvinyl Chloride), flame retardant PVC, PE, LSOH, HFFR |

Ogo okpomọkụ: | 0°C to 90°C |

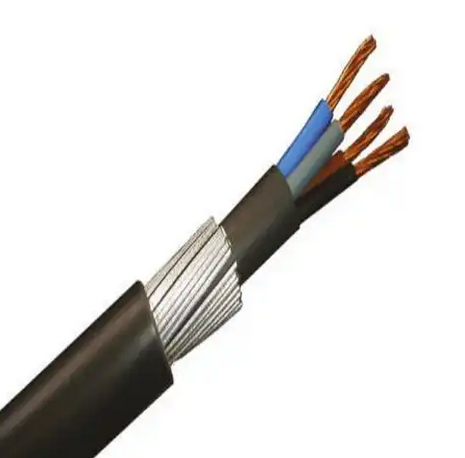

Armored Signal Subsea Electrical Cable

Armored Subsea Electrical Cables are protected by steel armor on the outside of the cable core, the insulation and the inside of the outer sheath, and therefore have strong mechanical strength against external pressure and stretching. And also can also fight against the corrosion of various acidic substances on the seabed, stronger water-blocking properties. It has a strong resistance to all kinds of interference in signal and power transmission. Armored submarine cables of this construction are mainly used in mining, underground, construction and submarine in the offshore range.

Ọkọlọtọ: IEC 60092-350, IEC 60287, IEC 60332, NEK 606, wdg.

Product Application | Underground/Mining/Construction/Submarine |

Jacket Material | PUR(TPU)/PVC/Rubber |

Onye nduzi | Stranded Pure Copper/Tinned Copper/Sliver Plated Copper |

Mkpuchi | PVC/PUR/TPE/TPEE/RUBBER/PP/PE |

Screen/Shielding | Optional |

Voltage | LV/MV/HV |

Sheath Color | Black/Red/Yellow/Orange/Grey/Green/Blue etc. |

Cable Diameter | According to your request for quotation and provided technical parameters |

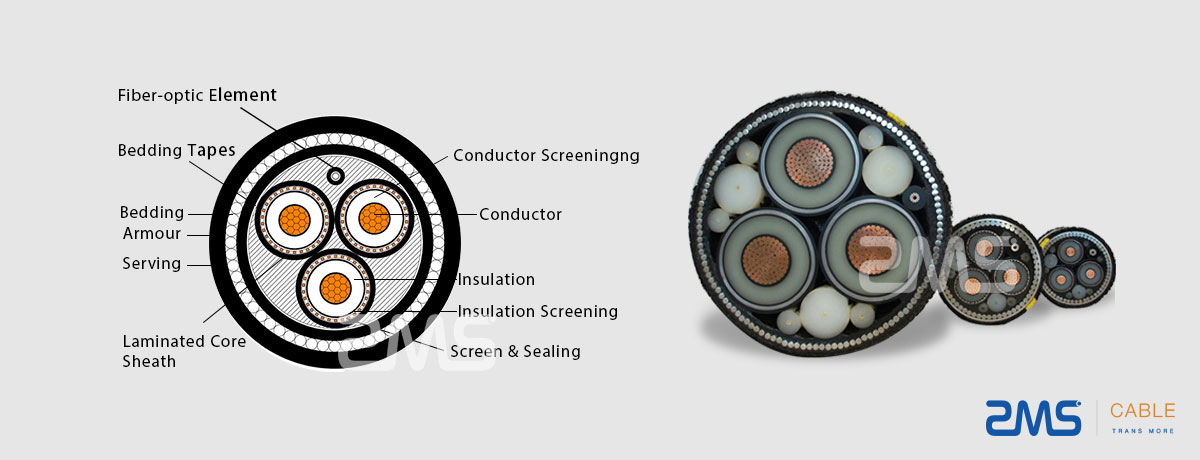

Subsea Composite Cable

Subsea Composite Cable is a major transmission cable that carries power below the water’s surface. It is also possible to use submarine power cables beneath the water. VERI USB has a series of advanced high-voltage cable and submarine cable production equipment capable of manufacturing onshore and submarine power cables of 500KV and below.

Ụdị & Purposes

– For offshore wind farm

– Export cable to transport the total generated power from the offshore substation to the onshore substation

– For interconnecting grids of countries

– Power supply from the mainland to isolated islands

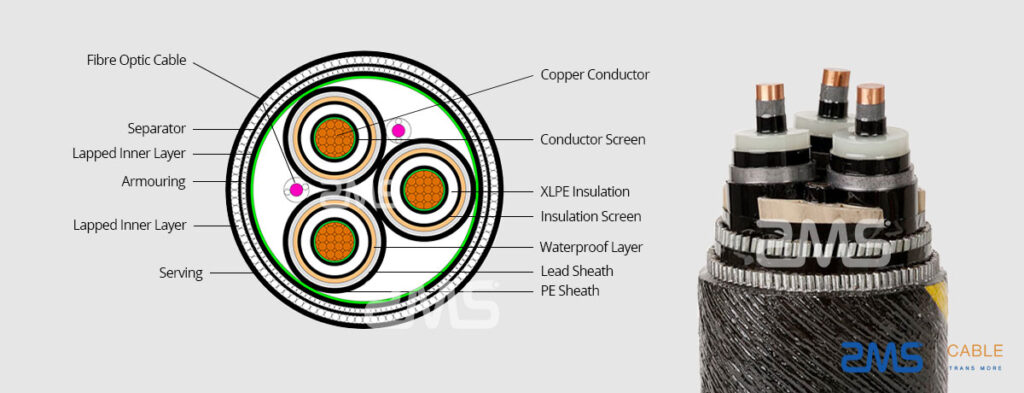

System voltage: | 30kV≤U≤500kV |

Onye nduzi: | Circular stranded copper or aluminum conductor constructed of round or profiled wires. |

Max. CSA 3000sq.mm | |

Mkpuchi: | Cross-linked polyethylene (XLPE) |

Metallic Screen: | 30kV≤U≤66kV: Copper wire, lead alloy sheath |

U≥110kV: Lead alloy sheath | |

Radial water barrier: | Semi-dry design: Laminated aluminum foil |

Dry design: Lead alloy sheath | |

Ngwa agha: | Three-core: Galvanized steel wire |

Single-core: Magnetic galvanized steel wire; Non-magnetic HD copper wire, stainless steel wire | |

Armor bedding & serving: | Polypropylene yarns |

We Also Produce the Following Submarine Electric Cable

N'ime submarine electric cable development so far, the structure has been designed to make a variety of exploration and experimentation, isi ihe owuwu gụnyere ụdị ndị a:

1. Impregnated Paper-Covered Submarine Cable

Kwesịrị ekwesị maka ihe karịrị 45kV AC na ọ bụghị karịa 400kV DC ahịrị. Ugbu a, ọ bụ naanị arụnyere na a mmiri omimi nke 500 m ma ọ bụ obere.

2. Oil-Filled Submarine Cable

Jiri usoro nke ime ime agbakwunyere iji kpochapụ oghere ikuku na eriri. Mgbe ikuku ikuku na-ebili, imp regnant na-agbasa, nrụgide dị n'ime eriri na-abawanye, na mmụọ ọjọọ na-achị na-asọba n'ime tank mmanụ. Mgbe eriri ahụ jụrụ, ndị dị ime na-ebelata, nrụgide dị n'ime eriri na-ebelata, and the pregnant in the oil supply tank flows into the cable again, na-egbochi ọgbọ nke ikuku ikuku. Ya mere enwere ike iji ya mee ihe 110 kV na n'elu ahịrị. Ịtọgbọ n'ime omimi mmiri ruo 500 m.

3. Enwere ike ịfụ ọkụ (Pressure-Assisted) Igwe okpuru mmiri okpuru mmiri

Iji akpa akwụkwọ impregnated nke eriri inflatable n'elu eriri mmanụ jupụtara na ya dabara adaba maka netwọk eriri ụgbọ mmiri dị ogologo.. Ma n'ihi mkpa ọ dị ịrụ ọrụ n'okpuru mmiri miri emi na-eji ikuku ikuku dị elu, si otú ahụ na-abawanye ihe isi ike nke ịmepụta eriri na ngwa ya, n'ozuzu oke na a mmiri omimi nke 300 m.

4. “Oil Pressure” Tube Submarine Cable

Naanị adabara ọtụtụ kilomita nke usoro eriri USB, n'ihi na eriri ogologo dị ogologo iji dọba n'ime ọkpọkọ, bụ n'okpuru nnukwu n'ibu mgbochi.

5. Extruded Insulation XLPE EPR Cables

Kwesịrị ekwesị maka voltaji AC ruo 200kV. Ethylene propylene roba na-eguzogide ọgwụ dendritic phenomena na ntapu mpaghara karịa polyethylene., ime ka eriri okpuru mmiri na-arụ ọrụ nke ọma.

Prospects Of VERI Subsea Power Cables

Mgbagwoju anya nke gburugburu mmiri nke ọrụ ụgbọ mmiri okpuru mmiri na-ebute ihe dị elu chọrọ, Injinia USB n'okpuru mmiri bụ nsogbu a ma ama n'ụwa, ihe isi ike ihe owuwu, na ọnụ ahịa mmezi dị elu. And it was only a few companies in the world can lay and commission submarine high-voltage cables. The development of the subsea power cable market has been greatly restricted. Okwu ndị ọzọ, ma ihe ngwọta maka nsogbu ahụ.

Significance of the VERI Submarine Cable

N'ọdịnihu, oghere ngwa nke eriri okpuru mmiri ga-aba ụba, it is important infrastructure equipment and is an important technical support for human beings to achieve the effective expansion of their activity area. Ọ na-ebufe ike oke osimiri dị ọcha na ala, na-ebelata esemokwu nke akụ na ụba ala, ma na-ebugakwa ike nke ala n'oké osimiri, na-enye aka na mmepe nke akụ na ụba oké osimiri. Veri Submarine Cable company firmly believes in this.

Customizable Cables from VERI cable Manufacturers

The submarine cable products produced by Veri cable factory include submarine power cables, eriri nkwurịta okwu okpuru mmiri, eriri optic okpuru mmiri okpuru mmiri, eriri n'okpuru mmiri, Igwe ịntanetị dị n'oké osimiri, na ngwaahịa ndị ọzọ. Achọpụtala ụdị ngwaahịa ọhụrụ dị iche iche na ikpe onwe ha, na-eburu n'uche ihe zuru oke nke akụrụngwa, ihe, Mmụba, ntughari arụmọrụ, àgwà na ọnụ ahịa, na mkpa iji mara oge kwesịrị ekwesị maka mmepụta. N'ihi na mainstream technology direction, ụlọ ọrụ ahụ echekwala maka mmepụta oke ma ga-ebupụta ngwaahịa dị iche iche dịka njirimara nke ahịa dị iche iche.

Ọrụ Ọkachamara anyị

Asambodo ogo

Ngwaahịa ndị VERI Cables rụpụtara na-agbaso ụkpụrụ mba ụwa dịka GB, IEC, BS, NFC, ASTM, SITE, wdg. Ọzọkwa, anyị oru otu nwere ike inye USB customization ọrụ maka gị mkpa.

Ndepụta ndị ahịa

VRI na-enye ọrụ ndụmọdụ USB ọkachamara n'efu, otu nkwụsị ọrụ ngwọta ọrụ, na ngwọta nnyefe ngwaahịa ngwa ngwa.

Ụgbọ njem ọkachamara

VORI eriri’ ihe mgbaru ọsọ mbụ bụ iji hụ na nnyefe ngwa ngwa na nchekwa nke ngwaahịa ma na-enye nkwakọ ngwaahịa kacha mma na njem njem iji belata ndị ahịa’ njem na-akwụ nnukwu ụgwọ.

Nkwakọ ngwaahịa USB

A na-ebunye nkwakọ ngwaahịa VERI na reels osisi, igbe corrugated, na eriri igwe. A na-eji teepu nkwụnye onwe BOPP mechie ngwụcha ya na mkpuchi mkpuchi na-abụghị hygroscopic iji chebe njedebe eriri site na mmiri.. Anyị nwere ike ibipụta akara ngosi achọrọ n'èzí nke drum na ihe anaghị egbochi mmiri dịka onye ahịa chọrọ.