Igwe ọkụ USB

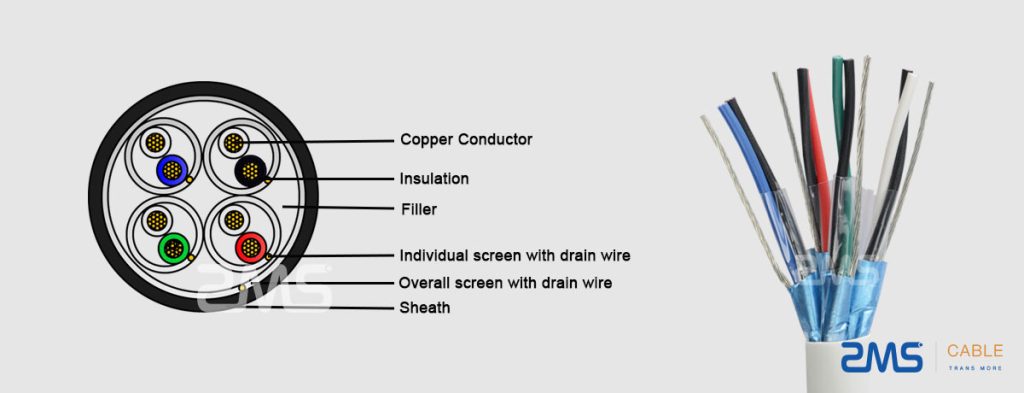

ZMS Cable specializes in producing and selling control cables, instrumentation cables, and cable accessories to date.

VERI Cable produces instrumentation cables manufactured using GB, IEC, BS, ASTM, ISO900, ISO14000, ISO14001, ISO18000, BS, CE, IEC, NFC, ASTM, and DIN certifications. This instrument cable type is moisture-proof, corrosion-proof, and damage-proof, and can be laid in tunnels or cable trenches.

Power control instrumentation cables are used to transmit and distribute high-power electrical energy on the main line of the power system, and control cables directly transmit electrical energy from the distribution point of the power system to the electrical connection lines of various electrical devices and appliances.

Instrument Cable Types

CU/XLPE Insulated Instrument Cable---Voltage Level 0.6/1KV

450/750v 0.5mm2 0.75mm2 1mm2 CU/XLPE insulated instrumentation cable

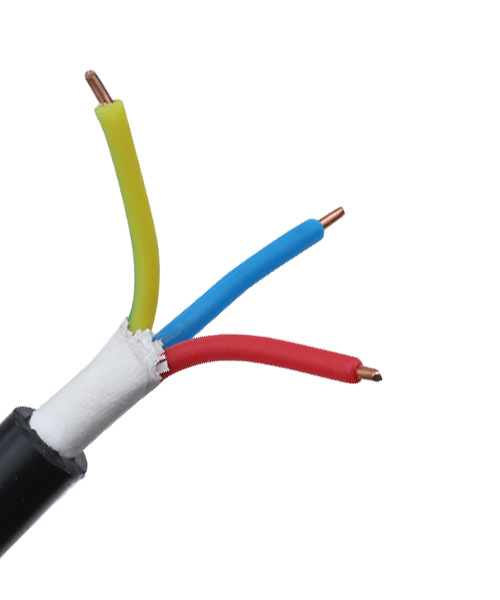

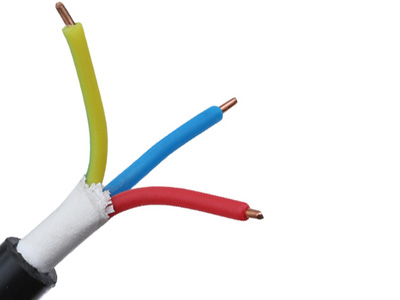

Construction

Onye nduzi: Annealed or tinned copper

Pairing: Two or three insulated conductors uniformly twisted together with a lay not exceeding 100 mm

Binder Tape: PETP transparent tape

Standard

IEC 60502, BS 5308, GB 9330

Uru:

Fire prevention, anti-impact, anti-rat, anti-mosquito, anti-radiation

Low working temperature

Strong overload resistance

Long service life, high safety, explosion-proof, corrosion resistance

High mechanical strength

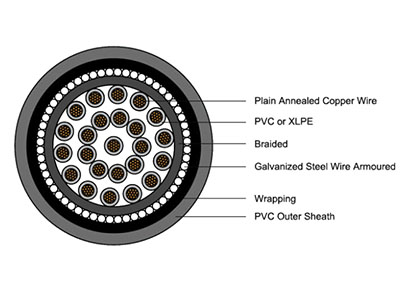

Shielding | Braid |

Jacket/Insulation | PVC/XLPE/PE |

Rated Voltage | 600V |

Size | 0.5mm2-1000mm2 customizable |

Ụdị | Low Voltage/Medium Voltage/High Voltage |

Certificate | ISO, CCC, CE, VDE |

Conductor Type | flexible |

Sheath | PVC Sheath |

Sheath Color | Black or blue |

Typically used in industrial process manufacturing plants for communications, data, and voice transmission of signals and services, and also for the interconnection of electrical equipment and instruments, usually in the oil industry.

Copper Tape Screened twisted pair Instrument Cable

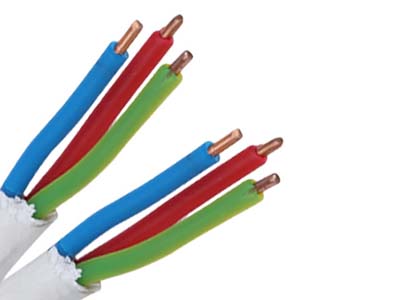

1. Design: LSZH (Low Smoke Zero Halogen) Instrumentation cable consisting of bare copper conductors, black & white, twisted pairs or black, white & red twisted triples with a continuous number sequence.

voltage test – 1500V, TECHNICAL DATA 0.5mm 1.5mm

Conductor Material | Copper/copper aluminum tinned copper wire aluminum alloy |

Insulation Material | PVC/XLPE |

Shielding | Foil |

Jacket | PVC |

Color | all kinds of color is available |

Standard | IEC BS ASTM DIN GB9330-1998 |

Sectional area | 0.75 mm2 – 10 mm2 |

armored | steel tape steel wire |

Inner Sheath | LSZH (Low Smoke Zero Halogen) Sheath |

Outer Sheath | LSZH (Low Smoke Zero Halogen) Sheath is flame retardant, conforms to IEC60332-3-22, halogen-free, conforms to IEC60754-1, low smoke emissions, conforms to IEC61034-1-2 |

Conductor sizes | 0.5 mm² solid, 1.0 mm² solid, 0.5 mm² flexible, 0.75 mm² flexible or 1.5mm²stranded |

Collective screen | 24 µm aluminum / PETP tape over tinned copper drain wire, 0.5 mm² |

Underwater Instruments Flat Flexible Shaft Electrical Cable

This product can be used as an underwater communication cable. It can be either a single network cable structure a coaxial cable structure, a network cable plus multicore power cable, or a coaxial cable plus multicore control cable structure. The network cable is more than Category 5 or Category 6, and the video cable is commonly used as 75-3/75-5, wdg. This product can also be used as an underwater telephone line. When using it, you can choose 2 pairs to use as video recording lines, and you can choose any pair to use as a telephone line or as a communication cable. It is simple to use and convenient to maintain.

Onye nduzi | multi strand super fine stranded oxygen free copper wire |

Insulation Material | high-densitywaterproof material |

Shielding | tinned copper wire fabric |

Jacket | seawater resistant polyurethane |

Color | core wires are distinguished by different colors |

Network cable type | CAT5E/CAT6/CA6A |

ike ọdụdọ | 100/300/500KGcustomized |

Rated voltage | 300/300V |

Collective screen | 24 µm aluminium / PETP tape over tinned copper drain wire, 0.5 mm² |

Water depth | 100M/200m/500m, wdg |

Bending radius of zero buoyancy steel wire mesh:

Fixed installation: 5 × Cable outer diameter (D)

Mobile installation: When the strokeis<10m, the bending radius is 7.5 × D When the stroke is ≥ 10m, the bending radius is 10 × D

VERI Transportation with Professional Service

Veri Cable nwere ọtụtụ ụzọ iji chebe eriri gị, nwere nkwakọ mbupu siri ike na ọkachamara yana mkpuchi zuru oke. Tupu mbupu, anyi eriri a na-akwakọba n'ime osisi reels na corrugated igbe. N'oge njem, iji chebe eriri eriri site na mmiri mmiri, anyị na-eji BOPP teepu na-ejide onwe ya na-abụghị hygroscopic mechie ha.

Ọ bụrụ na enwere nsogbu dị mma dịka nkwakọ ngwaahịa mebiri emebi na mmebi elu ngwaahịa n'ebe ahụ mgbe a na-anata ngwongwo, ọ bụrụ na achọpụtara na ngwongwo ahụ bụ eziokwu, ngwa ahịa adabaghị n'usoro, na nsogbu dị mma nke onye ahịa chọtara n'oge ntinye, A kwadoro usoro ịtọgbọ na iji ya bụ nsogbu dị mma nke ngwaahịa ahụ n'onwe ya, Ọ bụrụ na nnyefe adịghị na nkwekọrịta chọrọ, Biko kpọtụrụ ụlọ ọrụ anyị ozugbo.

Instrument Cable Installation and Wiring Tips

- —Under the eaves. Standard cables can be used only if the cable is not exposed to direct sunlight or extreme heat, and conduit is recommended. Do not use cables without UV protection in direct sunlight.

- —On the outer wall. Avoid direct sunlight on the wall and man-made damage. Heating cables are exposed to high temperatures in metal conduit or trunking, and many polymeric materials experience reduced service life at these temperatures.

- —In pipes (plastic or metal). If in pipes, pay attention to the damage to plastic pipes and the heat conduction of metal pipes. Once mechanical damage occurs, fiber optic cables are expensive to repair, requiring at least two terminations at each discontinuity point.

- —Suspended applications/overhead cables. Consider cable sag and stress. The cable is exposed to direct sunlight or not.

- —Directly laying in the underground cable trench, this environment is the smallest control range. The installation of the cable trench should be checked regularly for dryness or dampness. If the shield of the control cable needs to be grounded, the appropriate standards must be followed.