Direct Burial Fiber Cable

VERI Cable manufacturer’s direct burial fiber optic cable has good resistance to water, lateral pressure, and stretching. Direct burial cable is designed to be buried underground without a conduit. As a general rule, direct burial cable should be buried at least 24 inches to protect it from physical damage. Because direct burial fiber optic cable is perfect for underground installation. Our cable is armored and rodent-resistant. A rugged armored fiber cable to be buried directly in the ground or for installation in a conduit where rodents can still get inside.

Ponadto, our company also sells a variety of overhead cables, submarine cables, voltage cables, kable sterujące, itp. If you need anything, prosimy o kontakt z nami.

Gorące modele & Applications of Direct Burial Fiber Cable

G652D Single Mode Fiber Optic Cable

Cechy: low attenuation, long distance transmission, affordable.

Aplikacje: Widely used in metropolitan area networks (MAN), long-distance communications and fiber-to-the-home (FTTH).

G657A1 A2 Bent Fiber Optic cable

Cechy: excellent bending resistance, suitable for complex laying environment.

Aplikacja: For laying fiber optic cables in dense urban areas.

OM3 Multimode Fiber Optic Cable

Cechy: High bandwidth, suitable for short distance data transmission at 100Gbps.

Aplikacje: centra danych, local area networks (LAN).

Notatka: Including some OM4 advanced multimode fiber and special models of direct buried fiber optic cables, waterproof fiber optic cables, itp., VERI cables are supplied, please feel free to contact!

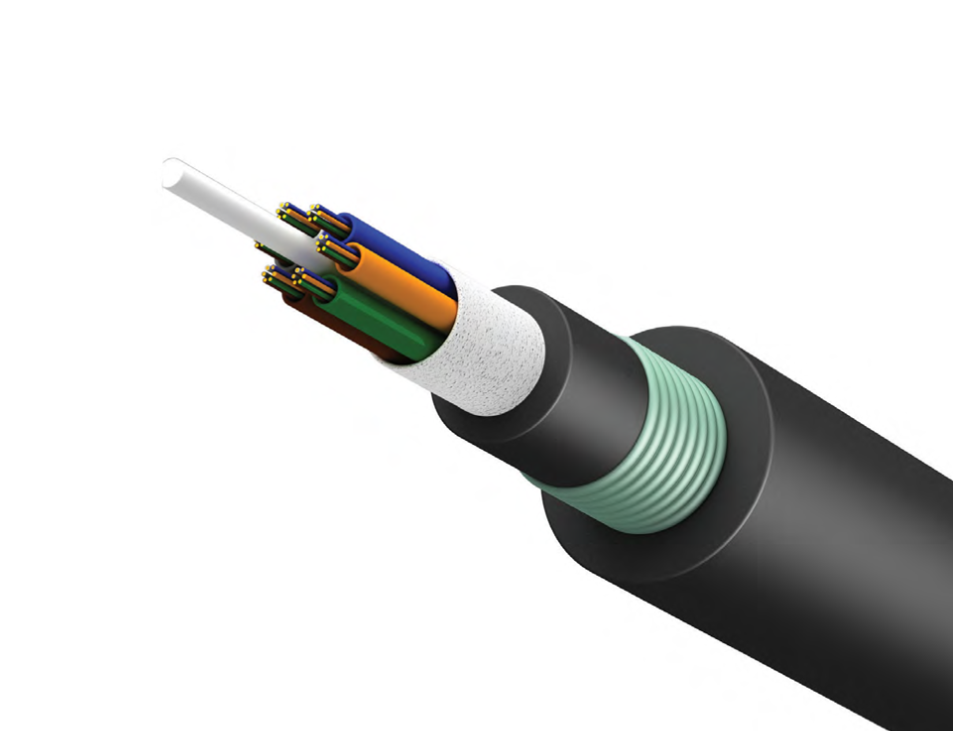

Double Armored 144 Core Fiber Optic Cable Sheaths GYFTA53

The structure of the GYFTA53 cable is that the 250 µm direct burial fiber is sheathed in a loose tube made of high-modulus material, and the flexible tube fills with a waterproof compound. The tubes are filled with a water-resistant filling compound. A Fiber Reinforced Plastic (FRP) is located in the center of the core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. An aluminum Polyethylene Laminate (APL) is applied around the cable core. Then the cable core is covered with a thin polyethylene (PE) inner sheath, which is filled with jelly to protect it from water ingress. After a corrugated steel tape armor is applied, the cable is completed with a PE outer sheath.

Features of GYFTA53 Optic Fiber

- Good mechanical and temperature performance

- High-strength loose tube that is hydrolysis resistant

- Special tube filling compound ensures the critical protection of fiber

- Crush resistance and flexibility

Dyrygent | multi strand super fine stranded oxygen free copper wire |

Number of Conductors | ≥ 10 |

Fiber Type | G652D Single mode or as your request |

Opancerzony | Steel Tape |

Cable Sheath | PE PVC LSZH HDPE/AT/Customized |

Inner Sheath | PE |

Instalacja | Conduit/Aerial/Direct/Air Blown |

Outer Sheath | PE |

- Single Fiber Reinforced Plastic as the central strength member

- Loose tube-filling compound

- 100% cable core filling

- APL moisture barrier

- PSP enhancing moisture-proof

- Water-blocking material

Application of GYFTA53 Optical Cable

- Long-distance communication, interoffice communication.

- It is especially suitable for occasions with high requirements for moisture-proof and rodent-proof.

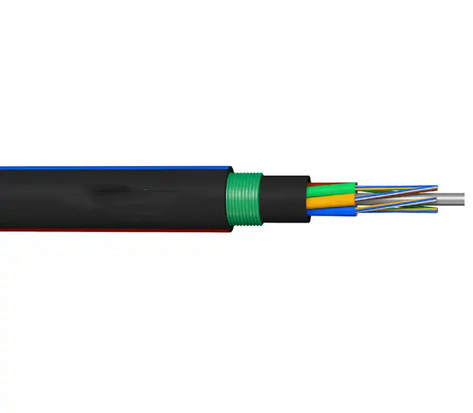

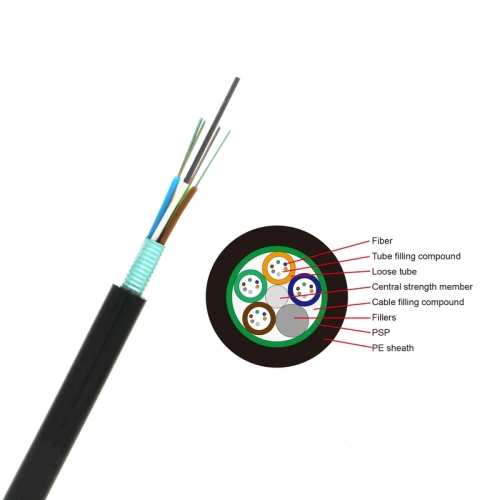

GYTY53 Direct Buried Double Sheathed Optical Cable

GYTY53 underground fiber optic cable is an outdoor communication optical cable of metal strength member of the loose tube jelly-filled structure, with polyethylene laminated sheath longitudinally covered with corrugated steel-tape armored polyethylene outer sheath.

The loose tubes are made of high-modulus plastics (PBT) and filled with water-resistant filling gel. Loose tubes are stranded around the metallic central strength member, and the cable core is filled with the cable-filling compound. Polietylen (PE) is extruded as an inner sheath, then water-swollen yarns and corrugated steel tape are longitudinally applied over the inner sheath, and combined with a durable PE sheath.

Cable type | Underground outdoor GYFTY53 fiber optic cable |

Material of jacket | HDPE/LSZH sheath/flame retardant sheath/anti-rodent sheath |

Temperatura robocza | -40deg℃to + 70deg℃ |

Fiber type | G652/G655/62.5/50/OM3 |

Color | Czarny |

Fiber core | 2-288rdzenie |

Bending Radius | Static 12.5*Cable-diameter: Dynamic 25*Cable-diameter |

Tube | Loose tube stranded/SZ stranded |

Fiber Count | Nominal Diameter (mm) | Nominal Weight (kg/km) | Max Fibers per Tube | Max No. of (Tubes+fillers) | Allowable Tensile Load (N) | Allowable Crush Resistance (N/100mm) | ||

Krótkoterminowe | Długoterminowe | Krótkoterminowe | Długoterminowe | |||||

2~30 | 12.2 | 142 | 6 | 5 | 3000 | 1000 | 3000 | 1000 |

32~48 | 12.8 | 155 | 8 | 6 | 3000 | 1000 | 3000 | 1000 |

50~72 | 13.6 | 170 | 12 | 6 | 3000 | 1000 | 3000 | 1000 |

74~96 | 15.0 | 192 | 12 | 8 | 3000 | 1000 | 3000 | 1000 |

98~144 | 16.6 | 220 | 12 | 12 | 3000 | 1000 | 3000 | 1000 |

>144 | Available upon customer’s request | |||||||

Funkcja

- High-quality optical fiber provides good transmission performance

- Accurate fiber excess length control ensures excellent mechanical and temperature performance

- Special filling gel filled loose tubes provide perfect optical fiber protection

- All section water blocking provides reliable performance of moisture-proof and water block

- Corrosion resistance phosphate steel wire with high Young’s modulus as central strength member gives high tensile strength

- Longitudinal corrugated steel tape presents desirable crush resistance

- Strict craft and raw material control enable a lifespan of over 30 lata

Application of GYTY53 Optical Cable

- Double sheath structure, excellent crush resistance performance.

- It can effectively prevent the damage to rodents.

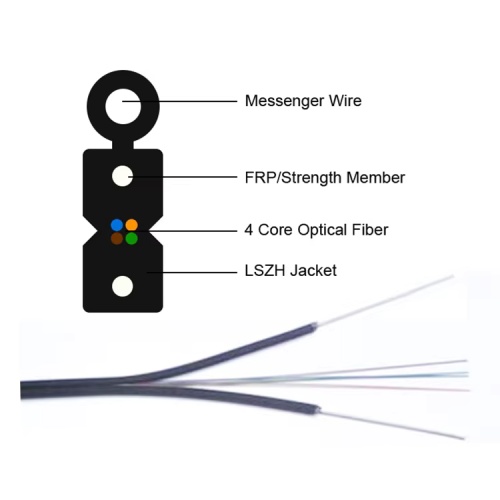

GYXTW Single Mode 12 Core Armored Optic Cable

GYXTW Armored Uni Tube Single Jacket/Single Armored cable is designed with the flexibility and versatility required for today’s most demanding installations, including direct buried. The metallic armor is used when mechanical protection is desired.

Cechy:

- Uni-tube gel-filled construction for superior fiber protection.

- Metallic armor to protect cable from rodent attack and mechanical damage.

- Embedded steel wire provide desirable tensile strength and crush resistance.

- Compact, easy to install.

- UV and waterproof design.

Cable type | Underground outdoor GYFTY53 fiber optic cable |

Material of jacket | PCV, LSZH, PE, PU, TPU, ect. |

Temperatura robocza | -40deg℃to + 70deg℃ |

Fiber type | G652/G655/62.5/50/OM3 |

Color | Czarny |

Fiber core | 2-288rdzenie |

Bending Radius | Static 12.5*Cable-diameter: Dynamic 25*Cable-diameter |

Tube | Loose tube stranded/SZ stranded |

Cable pack | Wooden Drum |

Fiber | 2-24 fiber |

Strength Member: | Steel Wire |

Zbroja | Corrugated steel tape |

Outer Jacket | Black UV Polyethylene(PE) |

Cable model | Number of fibers | Cable diameter mm | Cable weight kg/km | Allowable stretching force Long/short term N | Allowable crushing force Long/short term N/100mm | Bending radius Static/dynamic mm |

GYXTW-2~12 | 2~12 | 10.6 | 124 | 1000/3000 | 1000/3000 | 10D/20D |

GYXTW-14~24 | 14~24 | 12.5 | 149 | 1000/3000 | 1000/3000 | 10D/20D |

GYXTW-26~36 | 26~36 | 14.0 | 190 | 1000/3000 | 1000/3000 | 10D/20D |

GYXTW-38~48 | 38~48 | 15.0 | 216 | 1000/3000 | 1000/3000 | 10D/20D |

Return Loss | dB | ≥55 | ≥50 | ≥60 | ≥35dB | ≥35dB |

Insert-pull Test | dB | ≤0.2 | ≤0.2 | ≤0.3 | ≤0.15 | ≤0.15 |

Interchangeability | dB | ≤0.1 | ≤0.1 | ≤0.15 | ≤0.1 | ≤0.1 |

Temperature Range | ℃ | -40~+80 | ||||

Trwałość(1/Matings) | ≥1000 | |||||

Tensile Strength (N) | ≥90 (Φ3.0), ≥70 (Φ2.0), Φ0.9 | |||||

Fiber | 9/125um, 50/125um,62.5/125um,ect | |||||

Diameter | 0.9mm 2.0mm, 3.0mm etc | |||||

Cores | Simplex, duplex, 4rdzenie, 6rdzenie, 8rdzenie, 12cores etc | |||||

Aplikacja:

- Interbuilding voice or data communication.

- Installed in duct, underground conduit.

- FTTx.

Features of VERI Direct Burial Fiber Cable

- Waterproof Layer Design for Direct Buried Fiber Optic Cables

Direct burial fiber optic cables manufactured by VERI Cables are usually designed to achieve waterproof performance through multiple layers of protection, w tym waterproof coatings, moisture and water barrier tapes, aluminum foil shielding, and double jacket construction, among other measures. The excellent waterproof performance makes the cable more durable and stable environmental adaptability.

Model | Waterproofing Technology | Aplikacja | Material Structure |

G652D | Waterproof Coating + Water Resistant Tape | General underground communications network | Osłona HDPE |

G657A1/A2 | Waterproof Paste + Aluminum Foil Shield | Wet environments, complex wiring areas | Double PE sheath |

Armored Fiber Optic Cable | Moisture barrier + Armor layer | Scenarios with high water table and high mechanical pressure | Waterproof adhesive padding + outer jacket protection |

Special moisture-proof material | Laying of communications under high-voltage transmission lines | Waterproof Grease + Aluminum Sheathing |

- Design Features for Flame Retardant Fiber Optic Cables

VERI Cables produces fiber optic cables with flame retardant properties that are designed with the following structures: low smoke halogen free jacket materials, flame retardant additives, multi-layer jacket structures, armor layer protection, itp. Suitable for underground public facilities, petrochemical sites, centra danych, new energy facilities.

Model | Flame retardant Standards | Material Characteristics | Aplikacja |

G657A1 LSZH | IEC 60332-1/3 | Low smoke halogen free jacket, high temperature resistant | Urban communications, underground pipelaying |

G652D Armored Fiber Cable | UL 94 V-0 | Double Armor + Low Smoke Flame Retardant Jacket | High-risk areas such as tunnels and subways |

Fire-Resistant OPGW | W 50266 | Special fire retardant coating | High voltage grid transmission lines |

Nasze profesjonalne usługi

Certyfikat Jakości

Produkty produkowane przez VERI Cables są zgodne z międzynarodowymi standardami takimi jak GB, IEC, licencjat, NFC, ASTM, Z, itp. Ponadto, nasz zespół techniczny może świadczyć usługi dostosowywania kabli do Twoich potrzeb.

Śledzenie klientów

VERI świadczy bezpłatne, profesjonalne usługi doradztwa kablowego, kompleksowe usługi w zakresie rozwiązań projektowych, i rozwiązania w zakresie szybkiej dostawy produktów.

Profesjonalny transport

Kable VERI’ początkowym celem jest zapewnienie szybkiej i bezpiecznej dostawy produktów, przy jednoczesnym zapewnieniu najlepszych rozwiązań w zakresie pakowania i transportu, aby zmniejszyć liczbę klientów’ koszty transportu znacznie.

Opakowanie kablowe

Opakowania kablowe VERI dostarczane są w drewnianych szpulach, pudełka z tektury falistej, i cewki. Końcówki są uszczelnione taśmą samoprzylepną BOPP i niehigroskopijnymi zaślepkami uszczelniającymi, które chronią końcówki kabli przed wilgocią. Możemy wydrukować wymagane logo na zewnętrznej stronie bębnów za pomocą wodoodpornego materiału, zgodnie z wymaganiami klienta.