Subsea Electrical Cable

Kejbils elettriċi tal-baħar huma wajers elettriċi mgeżwra f'materjali iżolanti u li ma jgħaddix ilma minnhom u mqiegħda taħt l-ilma fuq qiegħ il-baħar u fix-xmajjar għat-trasmissjoni ta 'l-elettriku jew il-komunikazzjonijiet. Kejbils sottomarini jintużaw għall-qawwa tar-riħ barra mill-kosta, Pjattaformi tat-tħaffir barra mill-kosta, Interkonnessjonijiet tal-Grid tal-Gżira, Interkonnessjonijiet tal-Land Island u proġetti oħra barra mill-kosta biex jipprovdu komunikazzjoni u trasmissjoni ta 'enerġija.

Veri Submarine Power Cables ilha tirriċerka l-produzzjoni ta 'kejbils elettriċi subsea għal ħafna snin. Jekk hux mill-esplorazzjoni ambjentali tal-qiegħ il-baħar, Stħarriġ fiżiku tal-baħar jew studji ta ’każijiet ta’ proġetti kbar madwar id-dinja. Aħna nużaw ukoll disinn tal-kejbil avvanzat, Metodi ta 'Manifattura u Installazzjoni. Il-kejbils elettriċi subsea tagħna huma garantiti għal Reżistenza eċċellenti għall-ilma u lonġevità.

Mudell ta 'Prodotti tal-Kejbil Elettriku Subsea

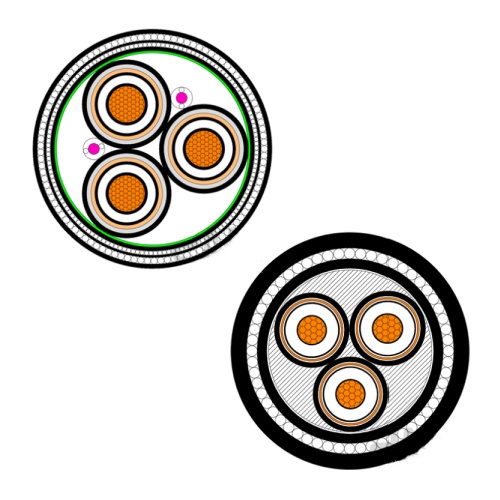

XLPE Kejbil Submarine Insulat

XLPE Insulat Subsea Power Cable għandu bosta vantaġġi fuq kejbil insulat bil-karta u insulat mill-PVC. Għandu saħħa elettrika għolja, Qawwa mekkanika, Reżistenza ta 'età għolja, Stress tal-metall ambjentali li jirreżisti s-salib anti-kimiku, U hija kostruzzjoni sempliċi, bl-użu ta 'tħaddim konvenjenti u ogħla ta' temperatura fit-tul. Jista 'jitpoġġa mingħajr restrizzjoni ta' qatra.

Applikazzjonijiet: Dawn il-kejbils tal-enerġija subsea huma adattati għal installazzjonijiet fissi fil-firxa offshore, bħal netwerks ta 'distribuzzjoni jew installazzjonijiet industrijali. Bħall-inġinerija tal-pjanti, makkinarju industrijali, Sistemi ta 'tisħin u arja kondizzjonata, power stations, eċċ.

Vultaġġ Rated: | 6/10kV, 6.35/11kV (12kV), 8.7/15kV, 12/20kV, 18/30kV,19/33kV |

Numru tal-qalba: | Qalba waħda jew tliet qalba (1C jew 3C) |

Dimensjonijiet disponibbli: | 25mm2, 35mm2, 50mm2, 70mm2, 95mm2, 120mm2, 150mm2, 185mm2, 240mm2, 300mm2, 400mm2, 500mm2, 630mm2. |

Mudelli | N2XSY, N2xsey, Na2xsy, Na2xKey, N2XSRY, NA2XSRY, N2xSeby, N2xseyby, Nasinseby, N2xsery, Na2xsery, N2xseeyrgby, NA2XSEIRGBY, YJV, YJLV, YJSV, Yjlsv |

Konduttur: | Konduttur tar-ram kompattat jew tal-aluminju tond mitluq (Cu / Al ), Wajer tar-ram ittemprat. |

Skrin tal-Konduttur: | Materjal semi-konduttiv |

Insulazzjoni: | XLPE (Polyethylene Cross-Linked) |

Skrin ta 'Insulazzjoni: | Materjal semi-konduttiv |

Skrin Metalliku: | Skrin tat-tejp tar-ram jew skrin tal-wajer tar-ram (CTS / CWS ) |

Virga: | Ħabel pp |

Separatur: | Tejp li jorbot |

Friex: | PVC (Klorur tal-polivinil) |

Armouring: | Qalba waħda: L-ebda multi-core: LE |

għant: | PVC (Klorur tal-polivinil), PVC ritardant tal-fjammi, PE, LSOH, HFFR |

Klassifikazzjoni tat-Temperatura: | 0° C sa 90 ° C. |

Kejbil elettriku tal-baħar tas-sinjal armat

Kejbils elettriċi tal-baħar armat huma protetti minn armatura tal-azzar fuq barra tal-qalba tal-kejbil, l-insulazzjoni u l-parti ta 'ġewwa tal-għant ta' barra, u għalhekk għandhom saħħa mekkanika qawwija kontra pressjoni esterna u tiġbid. U jista 'wkoll jiġġieled kontra l-korrużjoni ta' diversi sustanzi aċidużi fuq qiegħ il-baħar, Propjetajiet aktar b'saħħithom li jimblokkaw l-ilma. Għandu reżistenza qawwija għal kull tip ta 'interferenza fis-sinjal u t-trasmissjoni tal-qawwa. Kejbils ta 'sottomarini armati ta' din il-kostruzzjoni huma prinċipalment użati fil-minjieri, taħt l-art, kostruzzjoni u sottomarini fil-firxa offshore.

Standard: IEC 60092-350, IEC 60287, IEC 60332, To 606, eċċ.

Applikazzjoni tal-Prodott | Taħt l-art / minjieri / kostruzzjoni / sottomarini |

Materjal tal-ġakketta | PUR(TPU)/PVC / gomma |

Konduttur | Ram pur mitluq / ram tal-bottijiet / ram sliver miksi |

Insulazzjoni | PVC / pur / tepe / tepe / gomma / pe / pe |

Skrin / Shielding | Mhux obbligatorju |

vultaġġ | LV / MV / HV |

Kulur għant | Iswed / aħmar / isfar / oranġjo / griż / aħdar / blu eċċ. |

Dijametru tal-kejbil | Skond it-talba tiegħek għall-kwotazzjoni u pprovdiet parametri tekniċi |

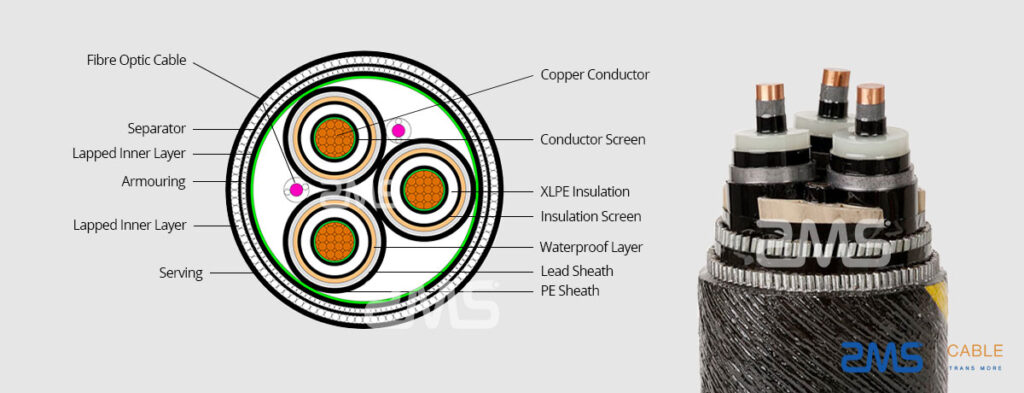

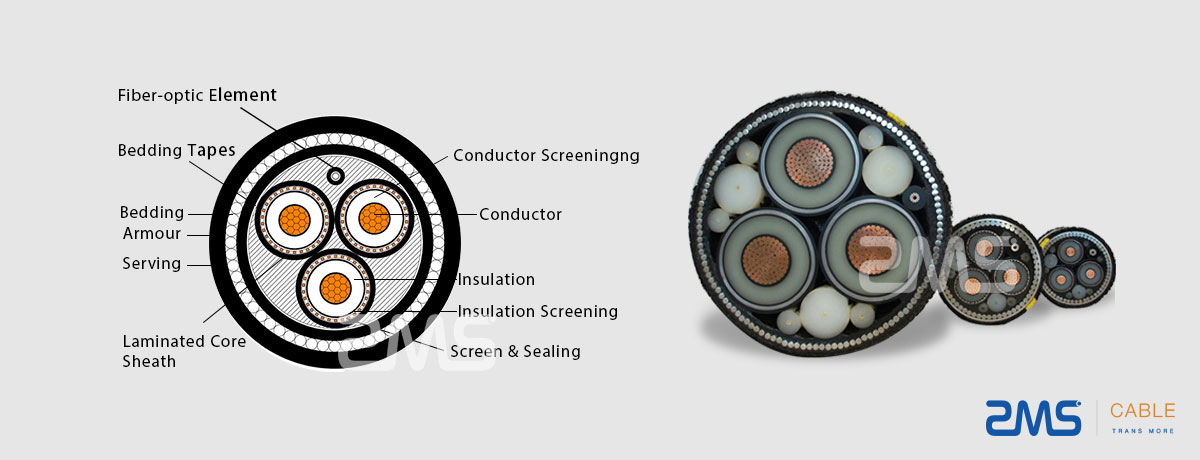

Kejbil kompost tal-baħar

Kejbil kompost tal-baħar huwa kejbil ta 'trasmissjoni maġġuri li jġorr l-enerġija taħt il-wiċċ tal-ilma. Huwa wkoll possibbli li jintużaw kejbils tal-enerġija sottomarini taħt l-ilma. Cable VERI għandu serje ta 'kejbil ta' vultaġġ għoli avvanzat u tagħmir ta 'produzzjoni tal-kejbil sottomarini li kapaċi jimmanifattura kejbils ta' enerġija onshore u sottomarini ta '500kV u taħt.

Tipi & Skopijiet

– Għal farm tar-riħ barra mill-kosta

– Kejbil ta 'esportazzjoni biex jittrasporta l-enerġija ġġenerata totali mis-substation offshore għas-substation onshore

– Għal grilji ta 'interkonnessjoni ta' pajjiżi

– Provvista ta 'enerġija mill-kontinent għal gżejjer iżolati

Vultaġġ tas-sistema: | 30kv≤u≤500kv |

Konduttur: | Ram ċirkolari mitluq jew konduttur tal-aluminju mibni minn wajers tondi jew profilati. |

Max. CSA 3000sq.mm | |

Insulazzjoni: | Polietilene marbut ma 'xulxin (XLPE) |

Skrin Metalliku: | 30kv≤u≤66kv: Wajer tar-ram, ċomb tal-għant tal-liga |

U≥110kv: Ċomb tal-għant tal-liga | |

Barriera radjali tal-ilma: | Disinn semi-niexef: Fojl tal-aluminju laminat |

Disinn niexef: Ċomb tal-għant tal-liga | |

Armatura: | Bi tliet qalba: Wajer tal-azzar galvanizzat |

Qalba waħda: Wajer tal-azzar galvanizzat manjetiku; Wajer tar-ram HD mhux manjetiku, Wajer tal-istainless steel | |

Friex tal-armatura & iservu: | Ħjut tal-polypropylene |

Aħna nipproduċu wkoll il-kejbil elettriku sottomarini li ġej

Fil Żvilupp tal-kejbil elettriku sottomarini S’issa, L-istruttura ġiet iddisinjata biex tagħmel varjetà ta 'esplorazzjoni u esperimentazzjoni, L-istruttura ewlenija tinkludi t-tipi li ġejjin:

1. Kejbil sottomarini miksi bil-karta mimli

Adattat għal mhux aktar minn 45kV AC u mhux aktar minn 400KV DC Lines. Bhalissa, huwa installat biss f'fond tal-ilma ta ' 500 m jew inqas.

2. Kejbil sottomarini mimli żejt

Uża l-metodu ta 'tqala supplimentari biex telimina d-distakk fl-arja fil-kejbil. Meta t-temperatura tal-kejbil togħla, L-Imp Regnant jespandi, Il-pressjoni ġewwa l-kejbil tiżdied, u r-regnant tad-dimostrazzjoni flussi fit-tank tal-provvista taż-żejt. Meta l-kejbil jibred, It-tqila tiċkien, il-pressjoni ġewwa l-kejbil tonqos, u t-tqila fit-tank tal-provvista taż-żejt terġa 'tidħol fil-kejbil, Il-prevenzjoni tal-ġenerazzjoni ta 'lakuni fl-arja. Allura jista 'jintuża għal 110 KV u Linji ta 'Fuq. Tqegħid fil-fond tal-ilma sa 500 m.

3. Li jintefħu (Assistita mill-pressjoni) Kejbil taħt il-baħar

L-użu ta 'basktijiet tal-karta mimlija ta' kejbil li jintefħu fuq kejbil mimli żejt huwa aktar adattat għan-netwerk itwal tal-kejbil sottomarini. Iżda minħabba l-ħtieġa li topera taħt ilma fond bl-użu ta 'pressjoni għolja ta' arja, b'hekk tiżdied id-diffikultà biex tfassal il-kejbil u l-aċċessorji tiegħu, ġeneralment limitat għal fond ta 'ilma ta' 300 m.

4. “Pressjoni taż-żejt” Kejbil ta 'sottomarini tat-tubi

Adattat biss għal diversi kilometri tas-sistema tal-kejbil, Minħabba l-kejbil twil ħafna biex jiġbed fil-pajp, huwa soġġett għal restrizzjonijiet mekkaniċi kbar.

5. Insulazzjoni estruża xlpe epr kejbils

Adattat għal vultaġġ AC sa 200kV. Il-gomma tal-etilene propilene hija aktar reżistenti għall-fenomeni dendritiċi u t-tnixxija lokali mill-polyethylene, Li tagħmel il-kejbils sottomarini jiffunzjonaw b'mod aktar effettiv.

Prospetti ta 'Veri Subsea Power Cables

Il-kumplessità tal-ambjent tal-baħar tal-proġett tal-kejbil sottomarini ressaq rekwiżiti għoljin, Inġinerija tal-kejbil taħt l-ilma hija problema rikonoxxuta fid-dinja, Diffikultajiet fil-kostruzzjoni, u spejjeż ta 'manutenzjoni għoljin. U kien biss ftit kumpaniji fid-dinja jistgħu jpoġġu u jikkummissjonaw kejbils ta 'vultaġġ għoli sottomarini. L-iżvilupp tas-Suq tal-Kejbil tal-Qawwa tas-Subsea ġie ristrett ħafna. Aktar kwistjonijiet, Iżda aktar soluzzjonijiet għall-problema.

Is-Servizzi Professjonali tagħna

Ċertifikazzjoni tal-Kwalità

Il-prodotti manifatturati minn VERI Cables jikkonformaw ma 'standards internazzjonali bħal GB, IEC, BS, NFC, ASTM, MINN, eċċ. Barra minn hekk, it-tim tekniku tagħna jista 'jipprovdi servizzi ta' customization tal-kejbil għall-bżonnijiet tiegħek.

Traċċar tal-Klijent

VERI jipprovdi servizzi ta' konsulenza professjonali b'xejn tal-kejbil, servizzi ta 'soluzzjoni ta' proġett one-stop, u soluzzjonijiet veloċi ta 'kunsinna tal-prodott.

Trasport Professjonali

Kejbils VERI’ għan inizjali huwa li jiġi żgurat kunsinna veloċi u sigura tal-prodotti filwaqt li tipprovdi wkoll l-aħjar soluzzjonijiet ta 'ppakkjar u trasport biex jitnaqqsu l-klijenti’ spejjeż tat-trasport ħafna.

Ippakkjar tal-Cable

L-ippakkjar tal-kejbil VERI huwa fornut f'rukkelli tal-injam, kaxxi korrugati, u coils. It-truf huma ssiġillati b'tejp li jwaħħal waħdu BOPP u tappijiet tas-siġillar mhux igroskopiċi biex jipproteġu t-truf tal-kejbil mill-umdità. Nistgħu nipprintjaw il-logo meħtieġ fuq barra tat-tnabar b'materjal li ma jgħaddix ilma minnu skond il-ħtieġa tal-klijent.