Instrumentation Cable

Instrumentation cables manufactured by VERI Cable are certified to GB, IEC, BS, ASTM, ISO900, ISO14000, ISO14001, ISO18000, BS, CE, IEC, NFC, ASTM and DIN.

To date, VERI Cable has produced instrumentation cables for use in a variety of applications and types, including fully automated production, power equipment, tunnel lighting, or laying into cable trenches. The length of the cables sold reaches more than 50,000 meters, and their resistance to moisture and corrosion is widely appreciated.

Types of Instrumentation Cables

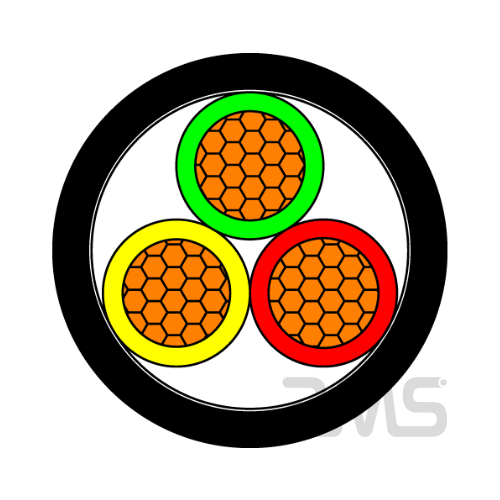

CU/XLPE Insulated Instrumentation Cable---0.6/1KV

Construction

Conductor: Annealed or tinned copper

Pairing: Two or three insulated conductors uniformly twisted together with a lay not exceeding 100 mm

Binder Tape: PETP transparent tape

Standard

IEC 60502, BS 5308, GB 9330

450/750v 0.5mm2 0.75mm2 1mm2 CU/XLPE insulated instrumentation cable

Shielding | Braid |

Jacket/Insulation | PVC/XLPE/PE |

Rated Voltage | 600V |

Size | 0.5mm2-1000mm2 customizable |

Type | Low Voltage/Medium Voltage/High Voltage |

Certificate | ISO, CCC, CE, VDE |

Conductor Type | flexible |

Sheath | PVC Sheath |

Sheath Color | Black or blue |

Advantages:

Fire prevention, anti-impact, anti-rat, anti-mosquito, anti-radiation

Low working temperature

Strong overload resistance

Long service life, high safety, explosion-proof, corrosion resistance

High mechanical strength

Typically used in industrial process manufacturing plants for communications, data, and voice transmission of signals and services, and also for the interconnection of electrical equipment and instruments, usually in the oil industry.

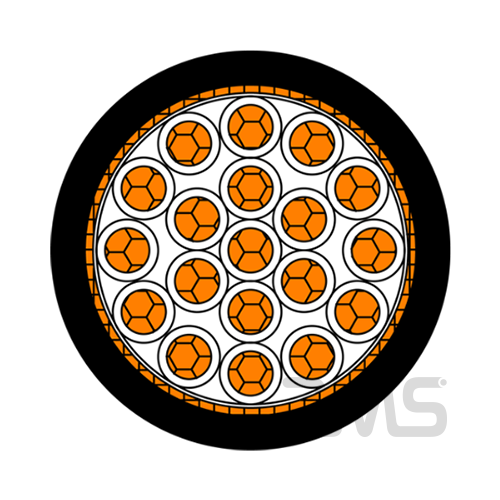

Copper Tape Screened Twisted Pair Instrument Cable

2. Voltage Rating: Rated Voltage Max. 300V a.c; Nominal Voltage A.C/D. C 110/150V, Test Voltage In process spark test – 4500V and AC withstand

voltage test – 1500V, TECHNICAL DATA 0.5mm 1.5mm

3. Operating Temperature: Minimum continuous operating temperature -25°C,75°C, 90°C, Minimum short circuit temperature 160°C (for 5 sec)

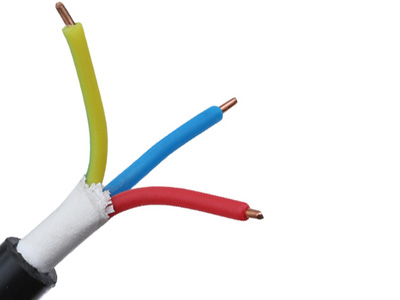

Conductor Material | Copper/copper aluminum tinned copper wire aluminum alloy |

Insulation Material | PVC/XLPE |

Shielding | Foil |

Jacket | PVC |

Color | all kinds of color is available |

Standard | IEC BS ASTM DIN GB9330-1998 |

Sectional area | 0.75 mm2 – 10 mm2 |

armored | steel tape steel wire |

Inner Sheath | LSZH (Low Smoke Zero Halogen) Sheath |

Outer Sheath | LSZH (Low Smoke Zero Halogen) Sheath is flame retardant, conforms to IEC60332-3-22, halogen-free, conforms to IEC60754-1, low smoke emissions, conforms to IEC61034-1-2 |

Conductor sizes | 0.5 mm² solid, 1.0 mm² solid, 0.5 mm² flexible, 0.75 mm² flexible or 1.5mm²stranded |

Collective screen | 24 µm aluminum / PETP tape over tinned copper drain wire, 0.5 mm² |

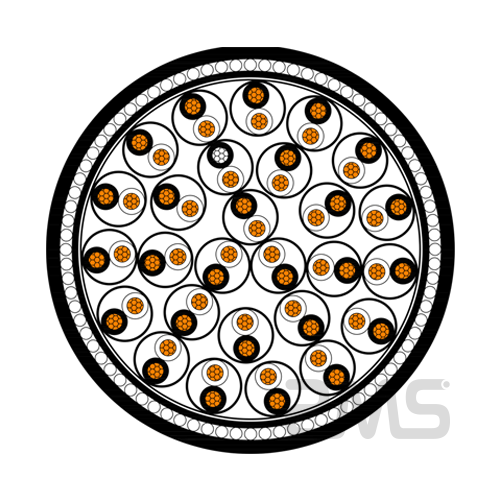

Underwater Instrumentation Flat Shaft Electrical Cable

This product can be used as an underwater communication cable. It can be either a single network cable structure a coaxial cable structure, a network cable plus multicore power cable, or a coaxial cable plus multicore control cable structure. The network cable is more than Category 5 or Category 6, and the video cable is commonly used as 75-3/75-5, etc. This product can also be used as an underwater telephone line. When using it, you can choose 2 pairs to use as video recording lines, and you can choose any pair to use as a telephone line or as a communication cable. It is simple to use and convenient to maintain.

Conductor | multi strand super fine stranded oxygen free copper wire |

Insulation Material | high-densitywaterproof material |

Shielding | tinned copper wire fabric |

Jacket | seawater resistant polyurethane |

Color | core wires are distinguished by different colors |

Network cable type | CAT5E/CAT6/CA6A |

tensile strength | 100/300/500KGcustomized |

Rated voltage | 300/300V |

Collective screen | 24 µm aluminium / PETP tape over tinned copper drain wire, 0.5 mm² |

Water depth | 100M/200m/500m, etc |

Bending radius of zero buoyancy steel wire mesh:

Fixed installation: 5 × Cable outer diameter (D)

Mobile installation: When the strokeis<10m, the bending radius is 7.5 × D When the stroke is ≥ 10m, the bending radius is 10 × D

Selection Tip: Selection of Instrumentation Cables in the Petrochemical Industry

The petrochemical industry, as one of the large industrial fields, has a harsh working environment involving temperature, pressure, corrosiveness and other extreme conditions, which puts higher requirements on the selection and design of instrumentation cables.

Select from VERI Instrumentation Cables:

— Cable Material:

In the petrochemical industry, cables made of corrosion-resistant, high-temperature-resistant, fire-retardant and flame-retardant materials are the first choice. PVC is suitable for general processes, and polyethylene PE is the first choice for oil-, acid- and alkali-resistant. VERI cables can be customized to be made of high-temperature materials, such as FEP, PFA, or silicone rubber.

— Cable Specifications and Performance:

| Conductor Structure | Logarithms | Maximum Nominal Outside Diameter (mm) | Nominal Weight (kg/km) |

| 1/0.8mm (0.5mm 2) | 2 5 10 20 30 | 9.7 12.9 17.7 22.9 27.3 | 100 190 320 570 820 |

| 16/0.2mm (0.5mm2) | 2 5 10 20 30 | 11.4 14.6 20.5 26.7 31.7 | 160 250 480 780 1100 |

| 24/0.2mm (0.75mm2) | 2 5 10 20 30 | 12.2 15.7 21.8 28.5 33.7 | 190 270 550 960 1320 |

| 1/1.13mm (1.0mm2) | 2 5 10 20 30 | 12.2 15.6 22.0 29.2 34.8 | 190 270 480 910 1320 |

| 7/0.53mm (1.5mm2) | 2 5 10 20 30 | 13.7 17.8 25.2 33.8 40.4 | 250 400 800 1400 2040 |

Note: Due to the different structure of instrument cables, this page only lists departmental specifications, you can always contact us about customized instrument cables.

Instrumentation Cable Installation and Wiring Tips

- —Under the eaves. Standard cables can be used only if the cable is not exposed to direct sunlight or extreme heat, and conduit is recommended. Do not use cables without UV protection in direct sunlight.

- —On the outer wall. Avoid direct sunlight on the wall and man-made damage. Heating cables are exposed to high temperatures in metal conduit or trunking, and many polymeric materials experience reduced service life at these temperatures.

- —In pipes (plastic or metal). If in pipes, pay attention to the damage to plastic pipes and the heat conduction of metal pipes. Once mechanical damage occurs, fiber optic cables are expensive to repair, requiring at least two terminations at each discontinuity point.

- —Suspended applications/overhead cables. Consider cable sag and stress. The cable is exposed to direct sunlight or not.

- —Directly laying in the underground cable trench, this environment is the smallest control range. The installation of the cable trench should be checked regularly for dryness or dampness. If the shield of the control cable needs to be grounded, the appropriate standards must be followed.

VERI Transportation with Professional Service

VERI Cable has multiple ways to protect your cables, with sturdy and professional shipping packaging and comprehensive insurance. Before shipping, our cables are packaged in wooden reels and corrugated box coils. During transportation, to protect the cable ends from moisture, we seal them with BOPP self-adhesive tape and non-hygroscopic.

If there are quality problems such as damaged packaging and product surface damage on the spot when the goods are received, if the goods are confirmed to be true, the goods do not match the order, and the quality problems found by the customer during the installation, laying and use process are confirmed to be the quality problems of the product itself, If the delivery is not in accordance with the contract requirements, please contact our company directly.