Armoured Electric Cable

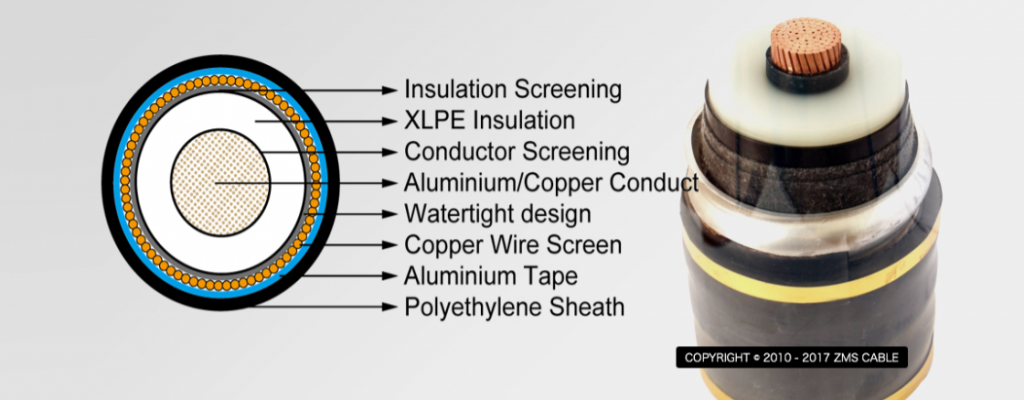

Armored cable does not have a specific model number, it refers to a large category in the classification of cables, VERI cable can be customized according to the customer to provide a variety of parameters and specifications for the appropriate armored cable products. VERI armored power cables are suitable for transmitting and distributing power in transmission and distribution systems from 0.6kv~35kv or lower voltages. It also prevents rodents from chewing through the armor which can cause power transmission problems. In addition to the above purposes, the addition of an armor layer to the cable enhances the mechanical protection properties such as tensile and compressive strength, and extends the service life.

Armored Cable Types and Sizes

Flexible Copper Oil Resistant PVC Armored Control Cable

The control cable can be produced according to the standard GB9330-1988, IEC, DIN, and BS, and the factory can also manufacture the cables by other standards.

Rated voltage: 450/750V

Conductor: Copper wire /tinned-copper wire, Class1, Class2, Class5

Insulation: PVC /PE /XLPE

Cabling: multicore stranded

Shield(if required): Copper tape or CWS or Al-plastic tape with drain wire

Inner sheath (applicable if there is an armor layer): PVC/PE

Armour layer: Galvanized steel wire / Steel tape

Outer sheath: PVC/PE/LSHF

Other characteristics: Oil resistant, Flame retardant, Anti-corrosion, UV, etc.

Product Parameter Specification

Type | Name | Section Area(mm2) | No. of Core | Application Site |

KVV | Copper Conductor,PVC Insulated and Sheathed Control Cable | 0.75 1.0 1.5 2.5 | 2-16 | Permanent installation indoors,in cable ditches or pipes |

4 6 | 2-14 | |||

10 | 2-10 | |||

KVVP | Copper Conductor,PVC Insulated and Sheathed,Braiding Shielded Control Cable | 0.75 1.0 1.5 2.5 | 2-61 | Permanent installation indoors,in cable ditches or pipes where shielding is required |

4 6 | 2-14 | |||

10 | 2-10 | |||

KVVP2 | Copper Conductor,PVC Insulated and Sheathed,Copper-tape Screened Control Cable | 0.75 1.0 1.5 2.5 | 4-10 | Permanent installation indoors,in cable ditches or pipes where shielding is required |

4 6 | 7-61 | |||

10 | 4-10 | |||

KVV22 | Copper Conductor, PVC Insulated and Sheathed, Steel tape Armored Control Cable | 0.75 1.0 1.5 2.5 | 7-61 | Permanent installation indoors,in cable ditches,Be able to withstand stronger external mechanical force |

Application

Control Cable is suitable for the connection of control equipment and monitor instruments and is also used as power and connecting cables in mechanical engineering for tooling machinery, control units, production lines, transportation equipment, conveyor and assembly lines as well as in plant construction under the circumstance that the rated voltage is up to 450/750V AC.

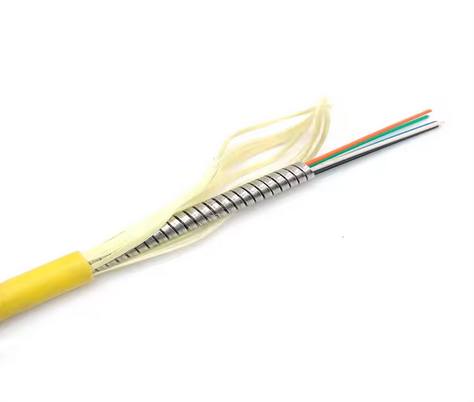

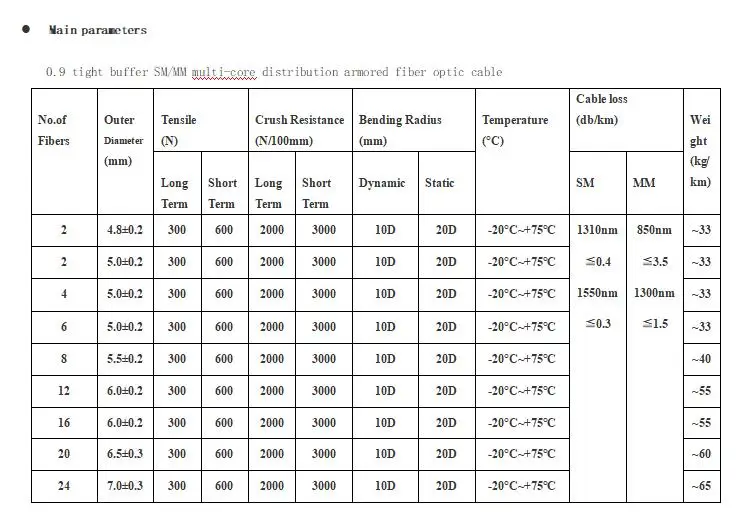

Stainless Steel Tube Flexible Armored Fiber Optic Cable

VERI Armored Fiber Optic Cables can be divided into indoor armored fiber optic cables and outdoor armored fiber optic cables according to the application of fiber optic cables. In addition, armored fiber optic cable can also be divided into interlocking armored fiber optic cable and corrugated armored fiber optic cable according to the different types of metal armor. Indoor armored fiber optic cable: indoor armored fiber optic cable includes single-layer armored and double-layer armored fiber optic cable.

Fiber Type: G.652D, G.657A1 or G.657A2 single mode fiber and OM1, OM2, OM3, OM4 mutimode fiber.

Application:

1. Applied to the patch cord of the optical terminal.

2. Indoor outdoor for FTTH and optical distribution, connection between optical cable and communication equipment room.

MC Armored 12/2 Flexible Metal Clad Cable

VERI Type MC Armored Cable can be used for feeder and branch circuit lines as specified in NEC. The insulation wire core of type MC cable is XHHW-2, it can be used in dry and wet locations with the highest working temperature not exceeding 90. The rated voltage of type MC cable is 600V. The cable consists of three or four XLPE insulated phase cores plus one bare ground conductor. Interlocked aluminum armor tape is applied over all the cables. A PVC jacket is optional. MC cable with PVC jacket provides extra durability. long-term reliability and installation security.

Conductor: AA-8030 aluminum alloy conductors

Insulation: Cross-linked polyethylene(XLPE) insulation

Armor: Interlock aluminum tape armor

Temperature Range: Temperature of 90 C in wet and dry locations

Environmental: Free of harmful heavy metals in compliance with RoHS

Voltage Rating:600Volt

Cable Data Sheet:

Conductor Size( AWG,Kcmil) | Nominal insulation Thickness | Nominal Overall Diameter | Approx.Weight |

inch | miles | lbs/1000ft | |

6-6-6-6 | 45 | 819 | 283 |

4-4-4-6 | 45 | 906 | 350 |

2-2-2-6 | 45 | 1016 | 446 |

Standard: ASTM-B,B-801 and B-836, UL standard 44 for XHHW-2, UL Standard 1569, RoHS environmental conductive requirement

Specifications:

The AA-8000 aluminum alloy conductor is applied in Type MC cable.

Its insulated core complies with the requirement of Type XHHW-2 in UL44.

Insulation material is cross-linked polyethylene(XLPE) with characteristics property, which can meet the FT2 level combustion test requirement.

MC cable, USA, UL & NEC standard, armored cable, metal-clad cable, AC cable, BX cable, TECK cable, interlocked armored cable.

Transportation with Professional Service

Export Experience

As a professional cable manufacturer, our cable products have been exported to many countries in the past 30 years, including the USA, Canada, Spain, UK, Germany, France, Russia, Greece, Saudi Arabia, etc. In these countries, our cable products are very popular with customers. And every year, because of our good quality and service, we would receive much good feedback from our customers.

Customized Cable Service

Our range of custom services includes design, size, and surface color. Many popular colors are also available for you to choose. We also specialize in over-sheathing, for example, we can make custom Polyethylene (PE) and Polyurethane (PUR) according to your requirements. We can provide solutions based on your ideas. Please contact us to give us your idea.

Strict Quality Inspection Standards

Veri Cable offers a wide variety of power cables based on trends and personal preferences. And we provide all kinds of power cables, more than 100 series. Then, to ensure the quality of the cables, we insist on testing our products once in a while.