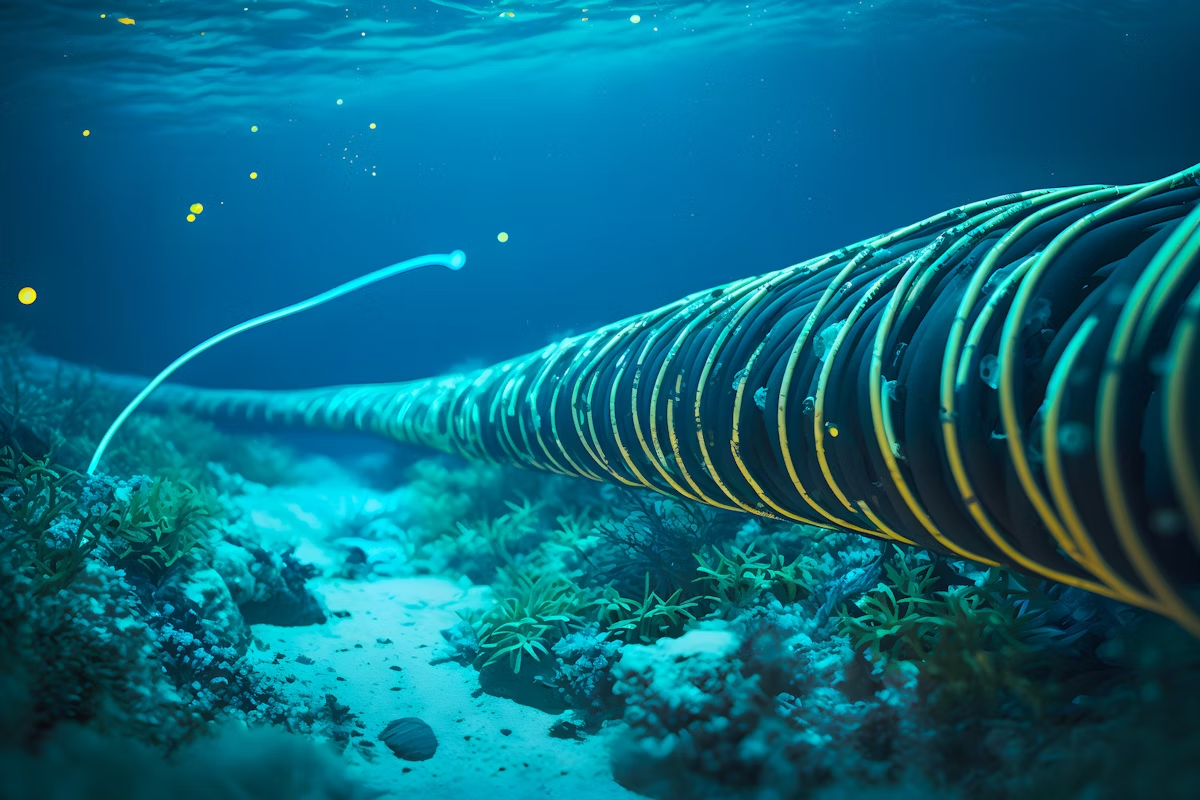

UNDERSEA POWER CABLE

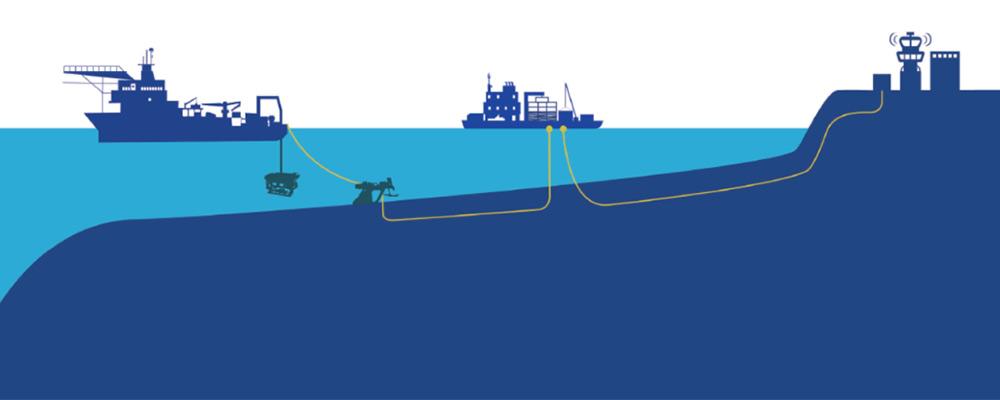

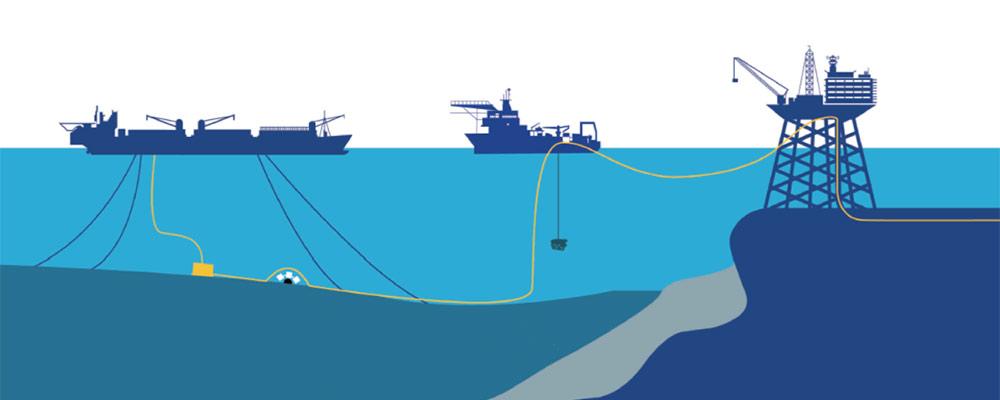

Undersea Electrical Cables are wires wrapped with insulating and waterproof materials and laid underwater on the seabed and rivers for power or communication transmission. The role of submarine cables is to provide communication and power transmission for offshore wind power, offshore drilling platforms, island grid interconnection, land island interconnection, and other offshore projects. VERI submarine power cable company has studied the production of submarine cables for many years. Whether from submarine environment exploration, marine physical investigation, and the world’s large projects’ case study. We also apply sophisticated cable design, manufacturing, and installation methods. The excellent performance and service life of our submarine cables are guaranteed.

NYY Cable 3-Core Submarine Power Cable

XLPE insulated power cable has several advantages over paper-insulated and PVC-insulated cable. XLPE power cable has high electric strength, mechanical strength, high-aging resistance, environmental metal stress resisting anti-chemical cross, and it is a simple construction, using convenient and higher operating of long term temperature. It can be laid with no drop restriction.

Application: These power cables are for fixed installations such as distribution networks or industrial installations. Such as Plant engineering;

Industrial machinery; Heating and air-conditioning systems; Power stations; Stage applications etc.

Rated Voltage: | 6/10kV, 6.35/11kV (12kV), 8.7/15kV, 12/20kV, 18/30kV,19/33kV |

Core Number: | Single Core or Three Core (1C or 3C) |

Available Dimensions: | 25mm2, 35mm2, 50mm2, 70mm2, 95mm2, 120mm2, 150mm2, 185mm2, 240mm2, 300mm2, 400mm2, 500mm2, 630mm2. |

Codes Available: | N2XSY, N2XSEY, NA2XSY, NA2XSEY, N2XSRY, NA2XSRY, N2XSEBY, N2XSEYBY, NA2XSEBY, N2XSERY, NA2XSERY, N2XSEYRGbY, NA2XSEYRGbY, N2XS(F)2Y, NA 2XS(F)2Y, N2XS(FL)2Y, N2XSH, N2XSYRY |

YJV, YJLV, YJSV, YJLSV | |

Application: | For power networks, outdoors and in cable ducting. It is recommended that the installation instructions indicated by the Local Electric Code, or any equivalent, be followed, so that the safeguarding of persons and the integrity of the product will not be affected during installation. |

Conductor: | Stranded round compacted copper or aluminum conductor (Cu / Al ), copper wire annealed. |

Conductor Screen: | Semi-conducting material |

Insulation: | XLPE (Cross-Linked Polyethylene) |

Insulation Screen: | Semi-conducting material |

Metallic Screen: | Copper tape screen or copper wire screen (CTS / CWS ) |

Filler: | PP rope |

Separator: | Binding tape |

Bedding: | PVC (Polyvinyl Chloride) |

Armouring: | Single Core: No Multi-core: No |

Sheath: | PVC (Polyvinyl Chloride), flame retardant PVC, PE, LSOH, HFFR |

Colour: | Red or Black |

Temperature Rating: | 0°C to 90°C |

Minimum Bending Radius: | Single Core: 15 x overall diameter Three Core: 12 x overall diameter (Single Core 12 x overall diameter and 3 core 10 x overall diameter where bands are positioned adjacent to joint or terminations provided that the bending is carefully controlled by the use of a former) |

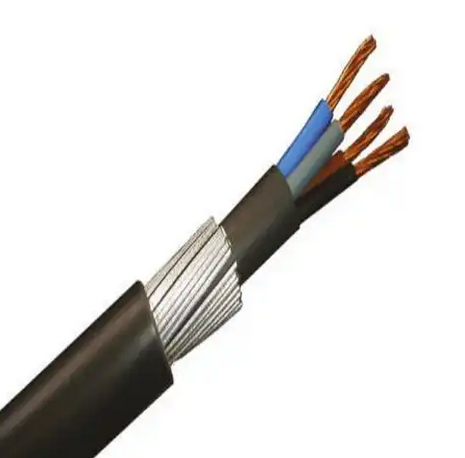

Insulated Armored Submarine Cable Electrical Control Signal Cable

With the protection of steel armor around the outside of the cable cores, their insulation, and the inside of the outer jacket, the armored cable is mechanically strong to outside pressure and stretching. It is highly resistant to various kinds of interference to/from its signal and power transmission. The main applications of armored cable are mining, underground, construction, and submarine.

Considering different working conditions and equipment to be applied, VERI’s cable products are highly customized. The high customization level of our cables can make sure that our products can best meet the demands in your pratical application. We welcome you to send a inquiry with specific requirements to our professional sales, and we will provide a technical sheet with cable drawings and detailed specifications to you, and of cource, a competitive quotation will also be send soon after your confirmation of the technical sheet. This can lead to your successful and efficient purchasing.

Product Name | Insulated Armoured Power Cable |

Product Application | Underground/Mining/Construction/Submarine |

Jacket Material | PUR(TPU)/PVC/Rubber |

Conductor | Stranded Pure Copper/Tinned Copper/Sliver Plated Copper |

Insulation | PVC/PUR/TPE/TPEE/RUBBER/PP/PE |

Screen/Shielding | Optional |

Voltage | 300/500V |

Sheath Color | Black/Red/Yellow/Orange/Grey/Green/Blue etc. |

Cable Diameter | As per Technical Sheet Provided Basing on Demands |

MOQ | 100M-200M |

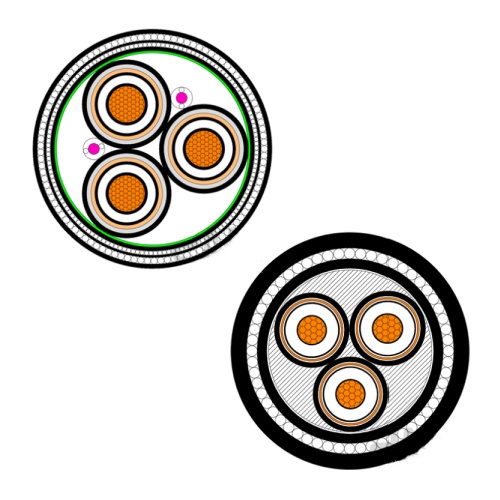

Subsea Composite Lead Sheath Submarine Cable

Subsea electricity cable is a major transmission cable that carries power below the water’s surface. It is also possible to use submarine power cables beneath the water. VERI Cable has a series of advanced high-voltage cable and submarine cable production equipment capable of manufacturing onshore and submarine power cables of 500KV and below.

Types & Purposes

– For offshore wind farm

– Export cable to transport the total generated power from the offshore substation to the onshore substation

– For interconnecting grids of countries

– Power supply from the mainland to isolated islands

System voltage: | 30kV≤U≤500kV |

Conductor: | Circular stranded copper or aluminum conductor constructed of round or profiled wires. |

Max. CSA 3000sq.mm | |

Insulation: | Cross-linked polyethylene (XLPE) |

Metallic Screen: | 30kV≤U≤66kV: Copper wire, lead alloy sheath |

U≥110kV: Lead alloy sheath | |

Radial water barrier: | Semi-dry design: Laminated aluminum foil |

Dry design: Lead alloy sheath | |

Armor: | Three-core: Galvanized steel wire |

Single-core: Magnetic galvanized steel wire; Non-magnetic HD copper wire, stainless steel wire | |

Armor bedding & serving: | Polypropylene yarns |

Submarine Cable Structure Types

In submarine electricity cable development so far, the structure has been designed to make a variety of exploration and experimentation, the main structure includes the following types:

1. Impregnated Paper-Covered Submarine Cable.

Suitable for not more than 45kV AC and not more than 400kV DC lines. At present, it is only installed at a water depth of 500 m or less.

2. Oil-Filled Submarine Cable.

Use the method of supplemental pregnancy to eliminate the air gap in the cable. When the cable temperature rises, the imp regnant expands, the pressure inside the cable increases, and the demon regnant flows into the oil supply tank. When the cable cools, the pregnant shrinks, the pressure inside the cable decreases, and the pregnant in the oil supply tank flows into the cable again, preventing the generation of air gaps. So it can be used for 110 kV and above lines. Laying in water depths up to 500 m.

3. Inflatable (Pressure-Assisted) Submarine Cable.

Using impregnated paper bags of inflatable cable over oil-filled cable is more suitable for the longer submarine cable network. But because of the need to operate under deep water using high air pressure, thus increasing the difficulty of designing the cable and its accessories, generally limited to a water depth of 300 m.

4. “Oil Pressure” Tube Submarine Cable.

Only suitable for several kilometers of the cable system, because the very long cable to pull into the pipe, is subject to great mechanical constraints.

5. Extruded Insulation XLPE EPR Cables.

Suitable for up to 200kV AC voltage. Ethylene propylene rubber is more resistant to dendritic phenomena and local leakage than polyethylene, making submarine cables function more effectively.

Prospects Of VERI Undersea Electric Cables

The complexity of the marine environment of the submarine cable project put forward high requirements, underwater cable engineering is a recognized problem in the world, construction difficulties, and high maintenance costs. And it was only a few companies in the world can lay and commission submarine high-voltage cables. The development of the subsea power cable market has been greatly restricted. More issues, but more solutions to the problem.

Significance of the VERI Submarine Cable

In the future, the application space of submarine cables will be broader, it is important infrastructure equipment and is an important technical support for human beings to achieve the effective expansion of their activity area. It transports clean ocean energy to the mainland, relieves the tension of mainland resources, and also transports mainland energy to the ocean, contributing to the development of the ocean economy. Veri Submarine Cable company firmly believes in this.

Customizable Cables from VERI cable Manufacturers

The submarine cable products produced by Veri cable factory include submarine power cables, submarine communication cables, submarine fiber optic cables, underwater cables, Internet cables in the ocean, and other products. A variety of new products have been researched and independently judged, taking into account the comprehensive factors of equipment, materials, yield, conversion efficiency, quality and cost, and the need to master the right timing for production. For the mainstream technology direction, the company has reserved for mass production and will launch differentiated products according to the characteristics of different markets.

Our Professional Services

Quality Certification

The products manufactured by VERI Cables comply with international standards such as GB, IEC, BS, NFC, ASTM, DIN, etc. Moreover, our technical team can provide cable customization services for your needs.

Customer Tracking

VERI provides free professional cable consulting services, one-stop project solution services, and fast product delivery solutions.

Professional Transportation

VERI Cables’ initial goal is to ensure fast and safe delivery of products while also providing the best packaging and transportation solutions to reduce customers’ transportation costs greatly.

Cable Packaging

VERI cable packaging is supplied in wooden reels, corrugated boxes, and coils. The ends are sealed with BOPP self-adhesive tape and non-hygroscopic sealing caps to protect the cable ends from moisture. We can print the required logo on the outside of the drums with waterproof material as per the customer’s requirement.