LSZH ELECTRIC CABLE

Low-Smoke Halogen-Free Cables have excellent flame retardant properties, little smoke when burning and no corrosive gases escaping. It is widely used in nuclear power plants, subway stations, telephone exchanges and computer control centers, high-rise buildings, hotels, radio and television stations, important military facilities, oil platforms, etc., as well as places with dense population and low air density.

The bending diameter of an LSZH multi-core cable is not less than 15 times the outer diameter of the cable, and the bending diameter of a single core is not less than 20 times.

Product Description

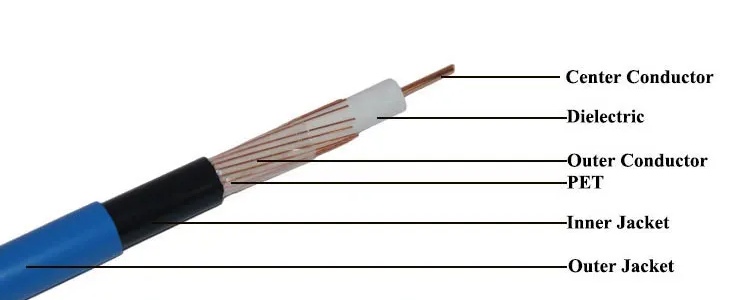

Reel Fire Retardant LSZH 75 ohm Dielectric Cable

The DAYTAI leaky feeder cable has a foam dielectric, which not only makes the cable more robust, but also prevents water from entering the inner core of the cable. Older air dielectric leaky feeder cable has a ‘hollow tube'(air dielectric) which aims to prevent the damage from the polluted mineralized water running down to the tube, filling up amp lifers, branches etc.

The DAYTAI leaky feeder cable has a radiation pattern of 360 degrees around the cable and can be strapped directly to a catenary cable, water or air pipe. The standard cable is available packing in 350m or 500M Wooden drum is optional.

VERI Cable Product Advantage

- Good quality

- Competitive price

- Multi-language service

- Professional technical support

- Over 30 years experience in Communication field

- Specializing in Communication cable and connectors

Number of Conductors | 1 |

Frequency | 5 to 500MHz |

Attenuation@160MHz | 4.2dB/100M |

DC Resistance Inner Conductor | <4.5 Ohm/KM |

DC Resistance Outer Conductor | <4.1 Ohm/KM |

Insulation Resistance | >10.4Mohm/KM |

Minimum Static Bend Radius | 150MM |

Operating Temperature | -40 to + 70 ℃ |

Crush resistance | 2200N/100mm |

Outer Sheath Diameter | 15.0mm+/- 0.2MM |

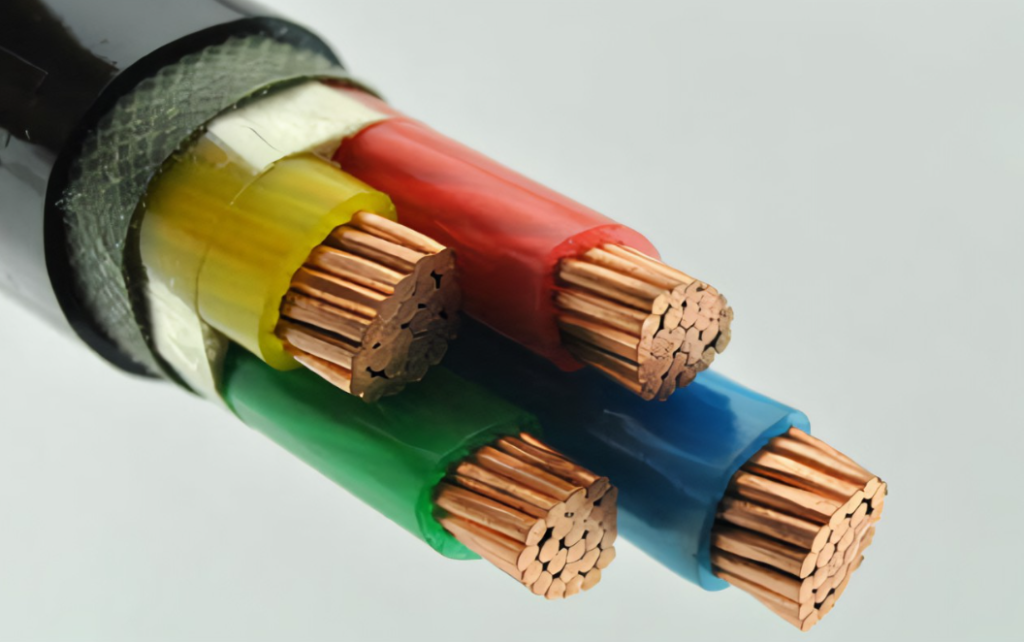

LSZH XLPE Insulation Fireproof Copper Core Cable

WDZN-YJV copper core polyethylene insulated PVC ring protective sheath fire-resistant power cable. When laid indoors, in tunnels and pipelines, the cable cannot withstand mechanical external forces. Single-core cables are not allowed to be laid in magnetic material pipelines. Fire-resistant cables are manufactured according to enterprise standards. The fire-resistant performance of the cables meets the requirements of the national standard GB 1266.6, and is divided into two different fire-resistant categories, A and B (950℃~1000℃/90 min, 750℃~ 800℃/min). Low-smoke and low-halogen flame-retardant cables are manufactured according to corporate standards. The flame-retardant performance of the cable meets the requirements of the national standard GB1266.5. The light transmittance is not less than 35%, and the hydrogen chloride release is not more than 100mg/g.

Application | Indoors, tunnels and pipes |

Type | Power Cable |

Certificate | CCC CE IEC |

Conductor | Copper |

Insulation | XPLE+Fire-resistant |

Sheath | LSZH |

Voltage | 0.6/1.0kV |

Packing | Roll |

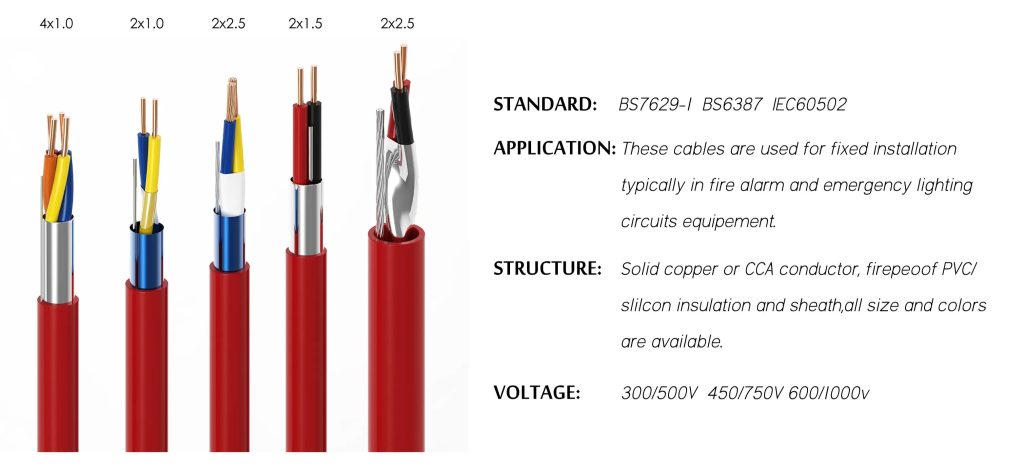

Insulation Requirements of LSZH Cables

Low-smoke Halogen-free Fuel

The temperature resistance grade of low-smoke halogen-free cable flame retardant sheath has 70℃ and 90℃, generally requires a product oxygen index of more than 32, has good mechanical performance and processing performance, can be widely used in power cable, communication cable, control cable, Marine cable and another sheath layer.

Low-smoke Halogen-free Cable Flame Retardant Insulating Material

The properties of low-smoke halogen-free flame-retardant insulating materials are similar to those of low-smoke halogen-free sheathing materials, and the insulation performance requirements are higher. It can be used for the insulating layer of power, communication, and electronic wires.

Low-smoke Halogen-free Flame Retardant Cable Flame Retardant Oxygen Barrier

The material is used for the inner sheath layer of power cables with high flame retardant requirements, which can improve the overall flame retardant effect of the cable and appropriately reduce the flame retardant requirements for the cable insulation sheath layer.

About VERI Cable After-Sales Service

First, Product Quality Commitment:

- There are quality records and testing data for the manufacture and testing of all cable products.

- For the inspection of product performance, we sincerely invite users to inspect the whole process and performance of the product in person. After the product is confirmed to be qualified, it will be packaged and shipped.

Second, the product price commitment:

- In order to ensure the high reliability of the product, the material selection of the system is made of domestic or high-quality products.

- Under the same competitive conditions, our company will sincerely provide you at an affordable price without reducing the technical performance of the product or changing the product components.

- Delivery time commitment:

Third, Product delivery time:

As far as possible according to user requirements, if there are special requirements that need to be completed in advance, our company can specially organize production and installation, and strive to meet user needs.

Fourth, after-sales service commitment:

- Service tenet: fast, decisive, accurate, thoughtful and thorough.

- Service objectives: service quality to win customer satisfaction.

- Service efficiency: If the equipment fails within the warranty period or outside the warranty period, after the supplier is notified, the maintenance personnel can reach the site and start maintenance within 24 hours.

- Service principle: The warranty period of cable products is twelve months. During the warranty period, the supplier will repair and replace the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, the provided accessories will only charge the cost the cost of equipment damage caused by human factors of the buyer, and the accessories repaired or provided by the supplier are calculated at cost.