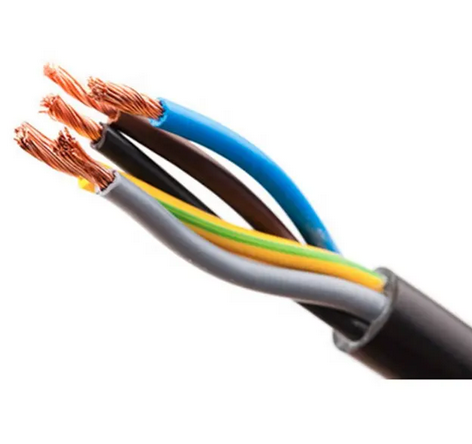

PVC Insulated Control Cable

VERI Cable specializes in control cables and cable accessories. Control cables such as instrument cables, armored control cables, flexible control cables, etc. We manufacture high-quality PVC insulated and PVC sheathed control cables suitable for industrial and mining enterprises, energy and transportation departments, and control and protection circuits with a rated AC voltage below 450v/750v. Veri Cable is a worldwide supplier of cable products. Our control cables are manufactured with GB, IEC, BS, ASTM, ISO900, ISO14000, ISO14001, ISO18000, BS, CE, IEC, NFC, ASTM, and DIN certifications.

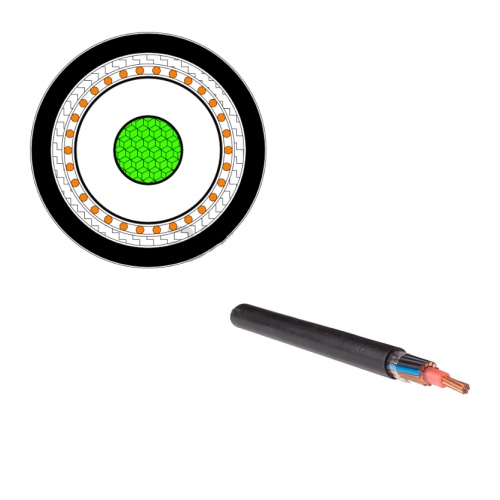

Control Shielded Cable Structure and Specifications

PVC Insulation Pure Copper Multi Core LIYCY YSLY-JZ Control Cable

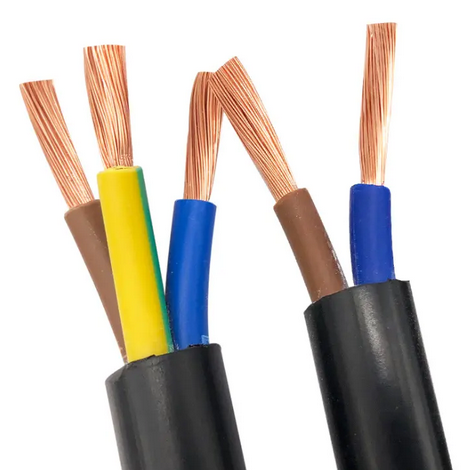

Copper core PVC insulated electric cable is a fine and ideal cable with the conductor of plain annealed copper wires, solid or stranded. These cables are used for general purposes, such as building wire for power, lighting, and control wire to electrical appliances, suitable for use in conduit and for fixed, protected installation. The cable can be of flame retardants, fire resistance, and other properties.

Application:

Use as home appliance wiring cable, building wire

Use as electrical and electronic equipment internal connecting wire

Use as lighting wire

House wiring cable

Product Standard:

The production standards for anti-flaming and fire-resistant cables are GB/T19666-2005, GB/T5023-2008, JB/T8734-2012

Conductor | High quality oxygen-free Copper |

Insulation | PVC |

Core | 1 2 3 4 5 |

Cross Section(mm2) | 1 1.5 2.5 4 6 10 16 25 35 50 |

Packing | 100m/Roll |

Cable Model and Name

| Model | Name | The main scope of use |

| KVV | Copper-core PVC Insulated PVC Sheathed Control Cable | Laying in indoor, cable trench, pipe, and other fixed places. |

| KVVP | Copper core PVC insulated PVC sheathed woven shielded control cable | Laying in indoor, cable trench, pipeline, and other fixed occasions requiring shielding. |

| KVVP2 | Copper core PVC insulated PVC sheathed copper strip shielded control cable | |

| KVVP3 | Copper core PVC insulated polyethylene sheathed aluminum plastic composite strip shielded control cable | |

| KVV22 | Copper core PVC insulated PVC sheathed steel strip armored control cable | Laying in indoor, cable trench, pipeline, direct buried, and other fixed occasions under large external forces. |

| KVV32 | Copper core PVC insulated PVC sheathed fine steel wire armored control cable | Laying in indoor, cable trench, pipeline, shaft, and other fixed occasions under large tension. |

| KVVP2-22 | Copper core PVC insulated polyethylene sheathed copper strip shielded steel strip armored control cable | Laying indoors, cable trenches, pipelines, direct buried, and others bear large mechanical external forces, requiring shielding fixed occasions. |

| KVVR | Copper core PVC edge sheathed soft control cable | Laying indoors and other mobile occasions. |

| KVVRP | Copper core PVC edge PVC sheathed woven shielded soft control cable | Laying in indoor, cable trench, pipeline, and other required shielding of the mobile occasions |

| Note: The model and name of the flame retardant and refractory series shall be GB / T 19666. Add ZA-, ZB-, ZC-, ZD-, and N- -to the conventional series cable model. | ||

Control Cable Specification and Range

Type | Rated voltage V | Conductor nominal cross-section mm² | |||||||

0.5 | 0.75 | 1 | 1.5 | 2.5 | 4 | 6 | 10 | ||

Number of cores | |||||||||

KVV | 400/750 300/500 | — | 2-16 | 2-14 | 2-10 | ||||

KVVP | |||||||||

KVVP2 | — | 4-16 | 4-14 | 4-10 | |||||

KVVP3 | |||||||||

KVV22 | — | 7-16 | 4-16 | 4-14 | 4-10 | ||||

KVV32 | — | 7-16 | 4-16 | 4-14 | 4-10 | ||||

KVVP2-22 | — | 7-16 | 4-16 | 4-14 | 4-10 | ||||

KVVR | 2-61 | — | — | ||||||

KVVRP | 2-16 | 2-48 | — | — | |||||

| Note: The recommended core number series are: 2, 3, 4, 5, 7, 8, 10, 12, 14, 16, 19, 24, 27, 30, 37, 44, 48, 52, and 61 cores | |||||||||

About VERI Cable After-Sales Service

First, Product Quality Commitment:

- There are quality records and testing data for the manufacture and testing of all cable products.

- For the inspection of product performance, we sincerely invite users to inspect the whole process and performance of the product in person. After the product is confirmed to be qualified, it will be packaged and shipped.

Second, the product price commitment:

- In order to ensure the high reliability of the product, the material selection of the system is made of domestic or high-quality products.

- Under the same competitive conditions, our company will sincerely provide you at an affordable price without reducing the technical performance of the product or changing the product components.

- Delivery time commitment:

Third, Product delivery time:

As far as possible according to user requirements, if there are special requirements that need to be completed in advance, our company can specially organize production and installation, and strive to meet user needs.

Fourth, after-sales service commitment:

- Service tenet: fast, decisive, accurate, thoughtful and thorough.

- Service objectives: service quality to win customer satisfaction.

- Service efficiency: If the equipment fails within the warranty period or outside the warranty period, after the supplier is notified, the maintenance personnel can reach the site and start maintenance within 24 hours.

- Service principle: The warranty period of cable products is twelve months. During the warranty period, the supplier will repair and replace the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, the provided accessories will only charge the cost the cost of equipment damage caused by human factors of the buyer, and the accessories repaired or provided by the supplier are calculated at cost.