BUILDING ELECTRIC CABLE

VERI Cables produces cables for the building industry, both in private homes and public buildings, whose safety, energy efficiency and flexibility of use significantly improve the quality of daily life of the inhabitants and the speed of city operations. Building power cables covers most cable categories, including low-voltage, medium- and high-voltage cables, retrofitting overhead electric lines, flame-retardant and fire-retardant wires, etc. VERI Cables has been in the business for more than 30 years and is committed to researching and manufacturing high-quality building-specific power cables, which are widely used in smart grids, energy and power, green buildings, smart manufacturing, and intelligent transportation. Environmental protection, safety, and reliability drive our production and development.

More Building Power Cable Types

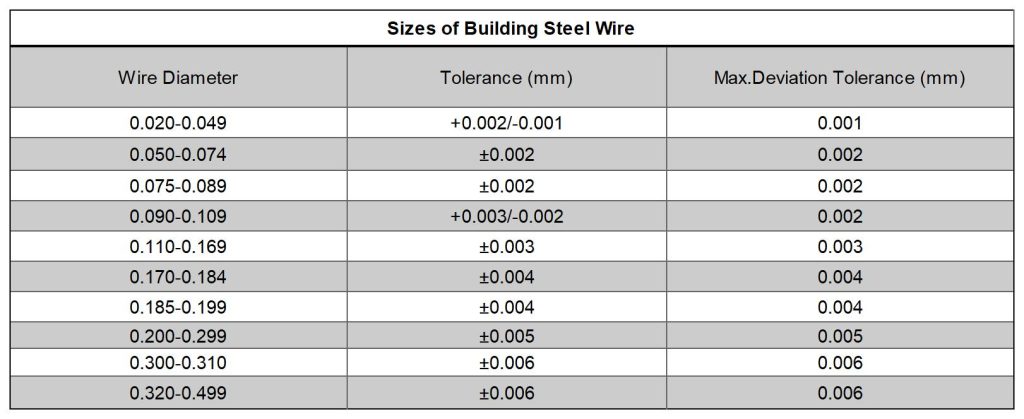

Building Steel Wire

VERI Cables produces construction steel-core bundled wire in 26-6 gauge standards for various applications. The cable is made of annealed steel, galvanized, or PVC insulated coated steel wire. The most common cable cross-section sizes range from 22 to 18 gauge (0.7 mm to 1.2 mm). They have a high tensile strength and are flexible and easy to cut or crimp, making them ideal for various applications such as construction, agriculture, and fencing.Material: galvanized wire, annealed wire, PVC coated wire

Wire Diameter: 0.45 mm – 5 mm (#26 – #6)

Common wire diameters: gauge 22 – gauge 18 (0.7 mm, 0.8 mm, 0.9 mm, 1.0 mm, 1.2 mm)

Tensile Strength: 300 – 480 Newton per square millimeter

Types: Coiled wire, U-shaped wire, cut wire, ring ties

Packing: rolled or spooled, lined with plastic film, outer woven bag

Annealed Lacing Wire: The surface is black annealed and coated with rust inhibiting oil, bright and rust free, soft, durable, and flexible. It is soft, durable and flexible. It can easily tie and fix the joints in place.

Galvanized Lacing Wire: Includes hot-dip galvanized and electro-galvanized wire. The surface is covered with a zinc layer, which gives it a shiny, silvery color. In addition, the zinc layer provides additional protection to extend its life. Generally, hot-dip galvanized tie wire has better corrosion resistance than electro-galvanized wire.

PVC-Coated Ligature Wire: Coated with PVC or PE coating, it provides excellent resistance to corrosion, dust, oil, chemicals, UV rays, etc. It has a service life of up to 12 years. It has a service life of up to 12 years. Colors available, such as green, black, yellow, white, etc.

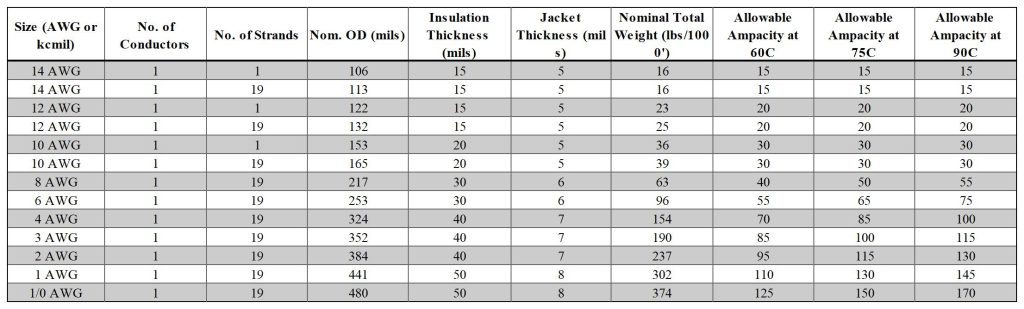

THHN Building Wire

VERI Cables manufactures THHN construction cable with thin, flame-retardant PVC insulation and an abrasion-resistant nylon jacket for use in dry environments up to 90ºC and wet environments up to 75ºC. Although THHN cables can be used in high temperature environments, the amperage of the cables must be corrected for high ambient temperatures and when bundling cables together in raceways or conduits. Model THHN construction cables are rated for a maximum of 600 volts and meet the UL 83 Standard for Safe Thermoplastic Insulated Wire and Cable as well as the UL 106 Standard for Safe Machine Tool Wire and Cable.

Additional standards are available upon request, so contact us today for more information.

Application Matters

VERI manufacturers are strict about copper conductor materials in the production of THHN cables, so most of the main products are suitable for use in conduit and cable trays for service, feeder, and branch circuits in commercial or industrial applications as defined by the National Electrical Code and are installed without the use of pullout lubricants.

Note that the allowable temperatures are as follows, depending on the product application:

1. THHN material: not to exceed 90°C in dry locations.

2. THWN: Wet locations at temperatures not exceeding 75° C or dry locations at temperatures not exceeding 90° C or exposed to oil at temperatures not exceeding 75° C. 2.

3. THWN-2: Wet or dry locations not exceeding 90° C or 75° C when exposed to oil.

4. TWN75: Wet locations not exceeding 75° C.

5. MTW: Wet locations or locations exposed to oil at temperatures not exceeding 60°C or dry locations at temperatures not exceeding 90°C (Ampacity is limited to that at a conductor temperature of 75°C per NFPA 79).

6. AWM: Dry locations shall not exceed 105°C only when rated and used as electrical wiring material.

Standards

1. ASTM – B3, B8, and B787 (19 Wire Combination Unilay-Stranded)

2. UL Standards 83, 758, 1063, and 1581

CSA C22.2 No. 75, T90 Nylon/TWN75 Sizes through 1000 kcmil

3. National Electrical Code, NFPA 70

4. CT Rated in Sizes 1/0 AWG and larger

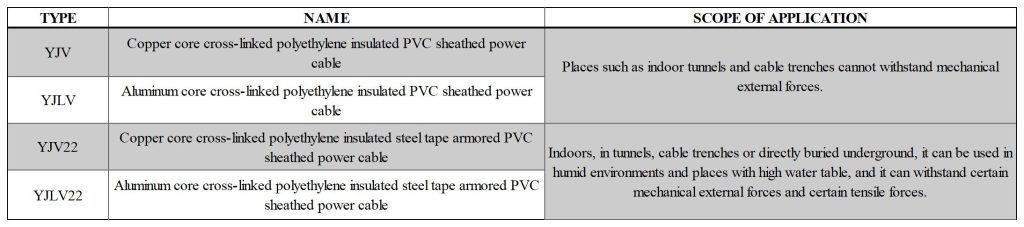

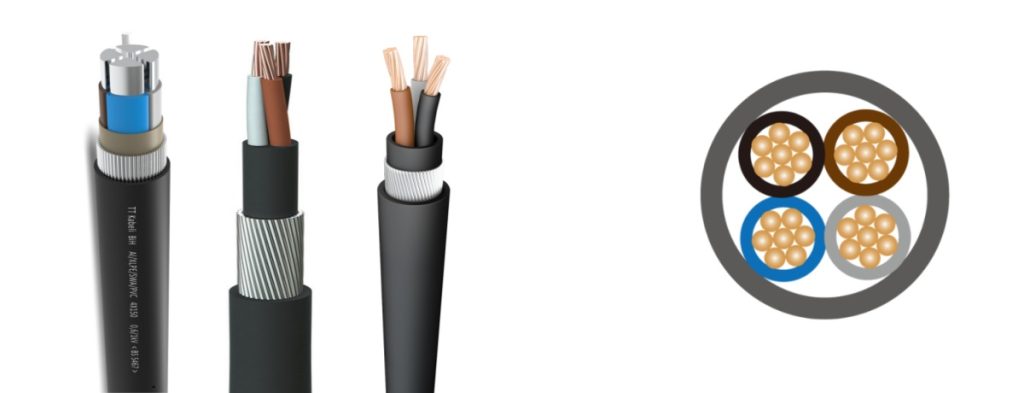

Building LV Cable

VERI Cables’ low voltage power cables for buildings include power-size UL tray cables and CSA Teck 90 cables, 3-conductors with grounding or 4-conductors with grounding products, with a wide selection of insulation shielding materials or armoring. Whichever cable you choose, you’ll experience outstanding reliability and maximum performance. You can also let us know your specific needs and VERI Cables will provide excellent customization.

CONSTRUCTION

Low Voltage Power Cable

— Copper(Aluminum) /XLPE(LSZH)/PVC(PE/LSZH)

—Copper(Aluminum)/XLPE(LSZH)/SWA(AWA)/PVC

(PE/LSZH)

— Copper(Aluminum) /PVC/PVC

— Copper(Aluminum) /PVC/STA(ATA)/PVC

The cables can be single core or multi-core with armored or unarmored as customer requirements.

LV power cable is used to transmit and distribute power on the power line, Uo/U is AC voltage 0.6/1kV.

Advantages of Choosing VERI Cables

Our construction-specific low voltage cables:

Durable: Conductors and sheath insulation are designed with specialized materials to withstand extreme environments.

Robust: the cables undergo a number of field tests to ensure that their performance in the power industry is significantly enhanced.

Customized Designs: Specialized customization is available based on the materials you need, including PVC/nylon, XLPE and EPR insulated conductors, as well as PVC, CPE or LSZH materials.

STANDARDS

IEC 60502, IEC 60332, IEC 61034, IEC 60754, IEC 60986, IEC 60287

Building LSZH Cable

VERI Cable recommends Low Smoke Halogen Free (LSZH) cables for use in public and government buildings and where sensitive electronic equipment is present, such as office towers, hospitals, supermarkets, airports, control rooms, computer rooms, etc. LSZH electric cables are designed for use in building construction to improve safety in the event of a fire: to reduce inhalation of the harmful, toxic smoke that is emitted when combustion occurs. It also reduces the amount of corrosive chemicals that can damage electronic equipment; most cables used in installations are insulated with PVC or similar materials. XLPE insulated halogen-free, low smoke cables are used in building construction to prevent asphyxiation from toxic gases produced by accidental burning of cables, such as fire-resistant, flame-retardant cables, which are less prone to catching fire, and which do not spread the fire or emit toxic gases in the event of a fire.

Conductor: Solid, Stranded Copper or Aluminum

Insulation: XLPE

Armoring: 1)Non-armored, 2)Steel tape armored (STA), 3)Steel wire armored (SWA), 4)Aluminum wire armored (AWA)

Sheath: LSZH material

Advantages of VERI LSZH Cables for Construction:

Our LSZH construction cables are rated at 600 V and have a maximum temperature of 90°C in wet or dry environments. These cables have excellent cold bending characteristics and are resistant to sunlight, weather, abrasion, and chemicals. Available in multi-core and multi-pair styles, they are suitable for installation in trays, raceways, trenches, ducts, pipes, and carriers.

These cables are insulated with EPR and have high dielectric strength and resistance to shrinkage, cuts, punctures, external forces, and abrasion. This model cable is certified to ICEA S-73-532 and ICEA S-95-658 (WC70) and IEEE 383 flame tested (70,000 btu) for use in Class 1 hazardous locations.

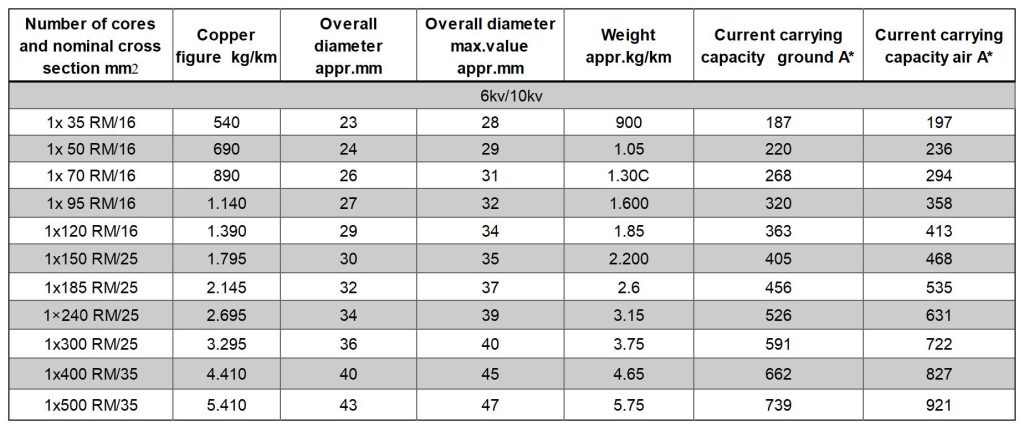

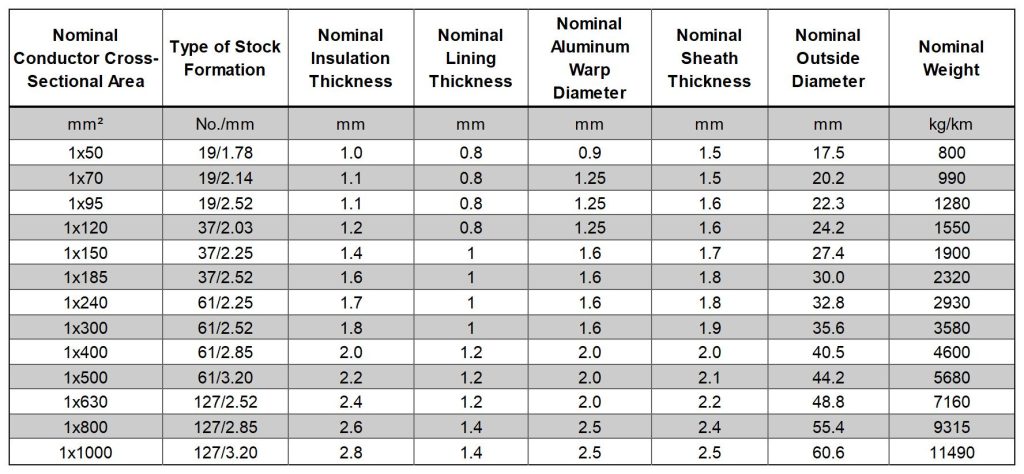

N2XSY Power Cable

The N2XSY is a popular version of the single-core cable with stranded copper conductors, XLPE insulation, and PVC sheaths for static and fixed installations both indoors and outdoors, as well as for direct installation in the ground or cable ducts.

VERI Cables manufactures N2XSY power cables per IEC 60502-2 and DIN EN 60228 Class 2. It is also self-extinguishing and flame retardant according to VDE 0482-332-1-2 and IEC 60332-1.

About N2XSY Model Specifications:

Model N2XSY cables are often used in distribution networks, substations, switching stations, and power plants, including in the field of renewable energies, due to their robust construction, low dielectric loss coefficients, and high operational reliability.

The N2XSY cables are red according to VDE 0276-603 and can be operated and installed at ambient temperatures from -5°C to +70°C. The cables are available in a wide range of colors, including red, black, yellow, and blue.

The construction of this type of cable is similar to that of NA2XSY cables, but the latter generally have an aluminum conductor, which can sometimes be used as a cost-effective alternative. In addition, we offer copper and aluminum cables with PVC jackets by the HD620 standard.

BS 5467 Armored Cable

BS5467 standard cables are suitable for power distribution and control circuits, VERI manufactures these cables with a steel armored construction for protection and therefore can be used in harsh environments such as inside buildings or buried underground.

| BS5467 Single Core | BS5467 Multi Core | |

| Voltage Rating | 0.6/1kV | 0.6/1kV |

| Conductor | Copper (Cu) (Class 2), Aluminium (Al) (Class 1) | 2 core to 48 core: Cu (Class 2), Al (Class 1) |

| Insulation | Cross-linked polyethylene (XLPE) | XLPE |

| Bedding | Polyvinyl Chloride (PVC) | PVC |

| Armour | Aluminum wire armour (AWA) | Steel wire armor (SWA) |

| Sheath | PVC | PVC |

BS5467 standard cables specifying the number of cores (single/double/triple/quad/five and up to 48 for auxiliary cables) and the type of conductor are widely used power cables in the UK. Highly resistant to abrasion, they are suitable for indoor, outdoor and underground use and can be buried directly in free draining soil or embedded in concrete. It is easy to lay and install without additional protection due to the mechanical protection provided by its armor and the UV stability and water resistance of the jacket.

If you have a need for BS5467 or other cable standards, please feel free to contact us.

Cooperation With VERI Cable

THHN Cable Project With Indonesia

VERI Cables successfully cooperated with Indonesia in 2022 for the supply of THHN construction cables for local civil engineering projects, totaling 2,500 meters, with models containing AWG8, 10/12, etc., which has been widely praised by customers.

N2XSY Cable Project With Nigeria

We cooperated with the Nigerian country on the project of 1000 meters of N2XSY, model: xxx, the other party fully affirmed our professionalism, product qualification and delivery cycle, and opened the next step of cooperation with VERI Cables.

Our Professional Services

Quality Certification

The products manufactured by VERI Cables comply with international standards such as GB, IEC, BS, NFC, ASTM, DIN, etc. Moreover, our technical team can provide cable customization services for your needs.

Customer Tracking

VERI provides free professional cable consulting services, one-stop project solution services, and fast product delivery solutions.

Professional Transportation

VERI Cables’ initial goal is to ensure fast and safe delivery of products while also providing the best packaging and transportation solutions to reduce customers’ transportation costs greatly.

Cable Packaging

VERI cable packaging is supplied in wooden reels, corrugated boxes, and coils. The ends are sealed with BOPP self-adhesive tape and non-hygroscopic sealing caps to protect the cable ends from moisture. We can print the required logo on the outside of the drums with waterproof material as per the customer’s requirement.