Different types of wires and cables have different sheath thicknesses, like rubber cables. They are mainly used in wear-resistant and cold-resistant places. And the insulating sheath is thicker. Generally, the higher the voltage level, the thicker the sheath. And the thickness of cables used for low-voltage electrical equipment generally does not mainly consider electrical properties, but mainly mechanical properties.

Rubber cables are widely used in various electrical equipment and can be used in indoor or outdoor environmental conditions.

Use Features of Rubber Cable

The rubber sheathed cable is mainly suitable for the connection of light mobile appliances (household appliances, power tools, etc.), instrumentation, and power lighting. The working voltage is below AC 750V, and most of them are AC 300V. Because the product needs to be moved, bent, twisted, etc. And the wire is required to be soft, and stable in structure. Then it has a certain degree of wear resistance. The plastic-sheathed cable can be laid directly in the soil.

When connecting with the power supply of electric heating appliances, braided rubber insulated cords or rubber insulated cords should be used as appropriate.

Structural Features of Rubber Cable

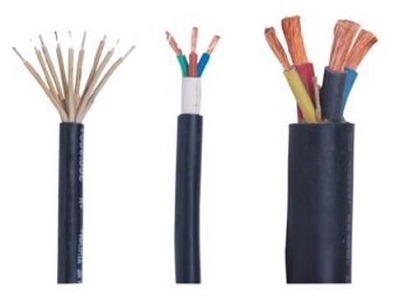

The conductive wire core is made of copper core, and the structure is of a soft type, which is a flexible wire conductor formed by twisting a plurality of single wire bundles. Insulation materials generally use natural styrene-butadiene rubber, polyvinyl chloride, or soft polyethylene plastics. The cable pitch multiple is smaller.

The outer protective layer of the rubber sheathed cable is woven with cotton yarn to avoid overheating and scalding the insulating layer. In order to facilitate use and simplify the production process, the three-core balanced structure is adopted, which can save production time and improve production efficiency.

The Future of Rubber Cable

Different from conventional products, the particularity of rubber sheathed cables is that different products need to be designed according to different customer requirements and application environments.

Rubber cable, with rubber insulating material as the insulating layer and sheath layer, is easier to recycle, and will not produce toxic gas when burning. It is consistent with the current state-advocated concept of environmental cables and is the future development of the wire and cable industry.