What is An RVV Control Cable?

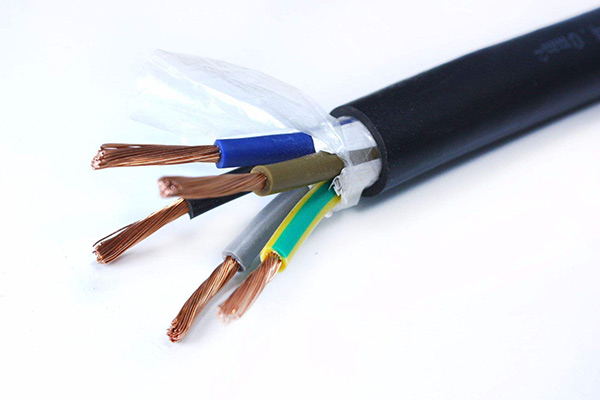

RVV control cable is known as copper core PVC insulated PVC sheathed flexible cable. It is also known as light polyvinyl chloride sheathed flexible cable, referred to as soft sheathed cable, is a kind of sheathed cable.

Because it is a soft core, RVV is generally used in narrow areas or places where it needs to be bent frequently. Mainly used in electrical appliances, meters, electronic equipment, and automation devices with power lines, control lines, and signal transmission lines, specifically for burglar alarm systems, building intercom systems, etc.

Use Characteristics

Rated working voltage: 300/500V

The long-term allowable working temperature of the cable is not higher than 70℃.

The maximum temperature of the cable conductor in case of a short circuit (the longest duration does not exceed 5s) does not exceed 160℃.

The ambient temperature when the cable is laid should be no less than 0℃, otherwise, it needs to be preheated beforehand.

Installation Bending Radius

a) The cable without an armor layer should be not less than 6 times the outer diameter of the cable.

b) Cable with an armored or copper tape shielding structure should be not less than 12 times the outer diameter of the cable.

c) flexible cable with shielding structure, should be not less than 6 times the outer diameter of the cable.

What is RVVP Control Cable?

RVVP is a kind of cable with soft conductor PVC insulation plus a shield and PVC sheath. Copper-core PVC insulated shielded PVC sheathed flexible cable, also known as electrical connection anti-interference flexible cable.

The “P” in RVVP refers to shielding, that is to say, RVVP wire has a shielding layer, and RVVP has a stronger anti-interference ability for external signals.

Rated voltage 300/300V, the number of cores commonly used is 2-19 cores.

Commonly used core wire diameter: 0.3 square, 0.5 square, 1 square, 1.5 square, 2.5 square, 4 square.

RVVP Cable Introduction

- RVVP implementation standard JB/T8734.5-2012

- Polyvinyl chloride insulation

- PVC sheath

- The conductor is a copper core stranded

- Aluminum alloy braided shielding network

- The rated voltage is 300/300V

- The normal working temperature is not more than 70℃

- The maximum temperature of the cable conductor does not exceed 160℃ during a short circuit (the longest duration does not exceed 5s). The ambient temperature when the cable is laid should be no less than 0℃, otherwise, it needs to be preheated beforehand.

RVVP Cable Application

The role of cable shielding is mainly to prevent the interference of external interference sources to the cable itself and the interference caused by the cable to other circuits. The use of a shielded cable and reliable grounding of the shielding layer is an effective measure to suppress its electromagnetic interference.

It is suitable for communication, audio, broadcasting, audio systems, burglar alarm systems, intelligent automation systems, automatic meter reading systems, fire-fighting systems, and other needs to prevent interference line connection, efficient and safe transmission data cable.

Talk About The Life Of The Control Cable

The service life of control cables is determined by the air oxidation induced period of the sheath raw materials. The general control cable is designed to be used for 20 years, which is the maximum life span of the control cable. Although it is possible to go longer in specific daily life, the design duration is the maximum life of control cables from a safety point of view.

The Life Of Control Cables

The elements that endanger the life of the control cable and the way to increase the life of the control cable.

- The control cable does not have to return to moisture, so as not to encounter heat and is subject to leaching. As the cable sheath on the cable is certain maintenance effectiveness, so the heat, and corrosion of the cable are more dangerous.

- Control cables do not have to overload applications. Overload application of the cable will lead to immediate damage to the cable insulation and sheathing, endangering the cable life or immediately destroying the cable.

- The old engineering building routes were found to be engulfed by water or wet. In particular, if the route is worn out to produce embrittlement should immediately ask the welders to give repair.

- Control cable to prevent common cable connector failure, common cable connector failure will lead to cable short-circuit failure, not only does the cable leads to damage, and even destroy household appliances.

- Control cable commodity itself: as far as possible to select the national industry standard cable, the cost-effective non-standard cable is very easy to lead to short-circuit failure, and non-standard cable life itself is short.

- Control cable belongs to the natural environment and temperature. Control cable is located in the external natural environment and heat sources can also lead to high-temperature control cables, insulation penetration, and even explosive fires.