With the development of science and technology, the quality of various construction projects is gradually improving. On the one hand, it is the application of advanced engineering technology, and on the other hand, it benefits from the increasing use of high-tech engineering materials in engineering. The application of MICC cable has provided great help for the quality improvement of construction projects. Mineral insulated cables, with their excellent characteristics of fire resistance, moisture resistance, and heat resistance, greatly ensure the safety of buildings.

The reason why mineral-insulated cables have these characteristics is closely related to their unique structure and materials. At present, there is not only one type of mineral-insulated power cable on the market. In addition to the commonly used BTTZ MICC cable, a variety of flexible mineral-insulated power cables have emerged in recent years. The representative one is the YTW type mineral insulated cable, both of which have common characteristics. However, there are differences in performance, so the actual application effects of the two are not the same, and they can be treated differently in specific construction applications.

MICC Cables from ZMS Cable Manufacturer

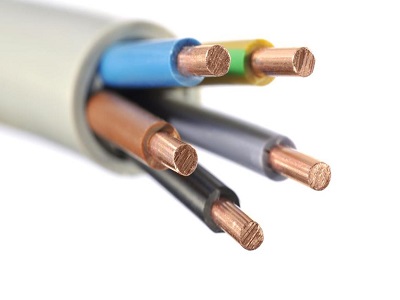

ZMS produces high-quality mineral insulated cables, with a copper sheath wrapped around the copper conductor core, and magnesium oxide powder as the inorganic insulating material to isolate the conductor and the sheath of the cable. That is to say, the magnesium oxide insulation layer is between the core conductor and the copper sheath, and the outermost layer can be selected according to the need for an appropriate outer sheath.

There is a similar cable with a metal sheath instead of a copper sheath covering the conductor core and magnesium oxide insulation, called mineral insulated metal sheathed cable.

Classification and Application of MICC Cables

Because the structure of mineral insulated cables is unique, and the materials used have inorganic insulating properties, compared with ordinary flame-retardant and fire-resistant cables, they have good fire resistance, oil resistance, high-temperature resistance, corrosion resistance, and other properties, and their weight is relatively high.

The current mineral insulated cables are mainly divided into two categories, one is the traditional mineral fireproof cables, namely BTTZ type mineral insulated power cables. The other is a flexible mineral insulated wire that has been emerging in recent years and has been well-used, namely YTTW type mineral insulated cable. The traditional mineral fireproof cable is insulated with magnesium oxide powder. This kind of MICC cable has been used for a long time. Our country has used this kind of mineral-insulated cable for nearly 30 years. Its mechanical properties are relatively good, but the laying requirements are relatively high. The cable installation process requirements are relatively high, and the space occupied is relatively large. Generally used in particularly important construction projects, such as super high-rise public buildings, super large commercial buildings, etc.

The flexible mineral insulated cable is a mineral insulated power wire that uses glass fiber and mica composite materials as insulation. It is more convenient to use and can be used in super high-rise residential buildings and other important large-scale commercial buildings and complex construction projects.

Selected the Length of Mineral Insulation Cables

When carrying out the construction of mineral-insulated cables, special attention should be paid to the length of the mineral-insulated cables, because the MICC power wires are customized by the cable manufacturer according to the required specifications, and their length cannot be arbitrarily selected. In construction, there is often a phenomenon that the delivery length of mineral-insulated cables is not considered carefully. Or there is a situation where the connection is made in the middle of the cable, which affects the efficiency of the cable. Therefore, before construction, it is necessary to compare the situation of the construction site in detail, determine the location of the installation cable, and carefully calculate the required cable length. In the actual cable procurement, it is about 1% more than the calculated length. To avoid the phenomenon of insufficient cable length during construction.