ZMS cable editorial comprehensively organized the cable classification and naming representation, but also made a detailed introduction to the cable classification, to help you have a better understanding of the cable purchase.

The focus of this article has the following three modules.

1 A general introduction to the cable naming rules and classification.

2 Communication cable naming methods and combined with specific examples.

3 Commonly used communication cables and power cables in design.

What are the types of cable classifications?

The distinction between wires and cables has no strict boundaries.

Usually, products with few cores, small product diameters, and simple structures are called wires, those without insulation are called bare wires, and others are called cables.

Conductor cross-sectional area greater than 6 square millimeters) known as large wires, less than or equal to 6 square millimeters known as small wires, insulated wire is also known as cloth wire.

Cable products are mainly divided into the following categories:

Bare wire and bare conductor products

The main feature of this product is pure conductor metal, with no insulation and sheath layer, such as steel-core aluminum stranded wire, copper and aluminum convergence, electric locomotive wire, etc.

The processing technology is mainly pressure processing, such as melting, calendaring, drawing, stranding tight pressure stranding, etc. The products are mainly used in suburban, rural, customer main lines, switchgear, etc.

Power Cable

The main feature of this product is extruded (winding) insulation layer outside the conductor, such as overhead insulated cables, or several cores stranded (corresponding to the phase, zero, and ground lines of the power system).

Such as more than two cores of overhead insulated cable, or then add a sheath layer, such as plastic or rubber cable. The main process technologies are drawing, stranding, insulation extrusion (wrapping), cable formation, armoring, sheathing extrusion, etc. The different process combinations of various products are somewhat different.

The products are mainly used in the transmission of strong electrical energy in the power generation, distribution, transmission, transformation, and power supply lines, through the current (tens of amps to thousands of amps), high voltage (220V to 500kV and above).

Cables for electrical equipment

The main features of this category are: a wide range of specifications, a wide range of applications, the use of voltage in 1kV and below more, in the face of special occasions continue to derive new products.

Such as fire-resistant cables, flame retardant cables, low-smoke halogen-free cables, termite-proof, rat-proof cables, oil-resistant or cold-resistant, temperature-resistant, wear-resistant cables, medical, agricultural, mining cables, thin-walled wires, etc.

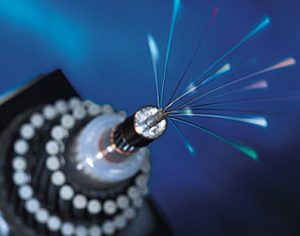

Communication cable and optical fiber

With the rapid development of the communication industry in the past two decades, the products have also had an amazing development rate.

In the past simple telephone and telegraph cables developed into thousands of pairs of words cable, coaxial cable, optical fiber cable, data cable, and even combined communications cable.

This type of product structure size is usually small and uniform, with high manufacturing precision requirements.

Electromagnetic wire (winding wire)

Mainly used for various motors, instruments, meters, etc.

All the above six categories of cables can consult ZMS cable suppliers for purchase.

Cable naming

The complete naming of cables is usually complicated, so people sometimes use a simple name, usually the name of a category combined with the type specification, to replace the complete name.

For example, “low-voltage cable” stands for all plastic insulated power cables of 0.6/1kV class.

Naming principles

The cable product name mainly includes the following elements:

(1) Product application or size class name

(2) Product structure material or type

(3) Important features or additional features of the product

Named in the above order, sometimes to emphasize the important or additional features, the features are written in front or before the corresponding structure description.

The overall principle of product structure description is following the principle of inside to outside: conductor → insulation → inner sheath → outer sheath → armor type.

Power cable naming method

The type composition and order of power cables are as follows:

Category – conductor – insulation – inner sheath – structural characteristics – outer sheath or derivative – make manganese wine container

Which 1-5 items and item 7 with the phonetic alphabet, polymer materials with the first letter of the English name, each item can be 1–2 letters; item 6 is 1–3 numbers.

Cable category

ZR (flame retardant), NH (fire-resistant), DDZ (low smoke and low halogen), WDZ (low smoke and halogen-free), K (control cable category), DJ (electronic computer), N (agricultural direct burial), JK (overhead cable category), B (cloth wire), TH (for hot and humid areas), FY- (termite-proof, corporate standards), etc.

Cable conductor

T (copper conductor), L (aluminum conductor), G (steel core), R (copper flexible wire).

Cable insulation

V (polyvinyl chloride), YJ (cross-linked polyethylene), Y (polyethylene), X (natural butadiene rubber mixture insulation), G (silicone rubber mixture insulation), YY (ethylene-vinyl acetate rubber mixture insulation).

Cable sheath

V (polyvinyl chloride sheath), Y (polyethylene sheath), F (neoprene mixture sheath).

Cable shielding

P (copper mesh shield), P1 (copper wire winding), P2 (copper tape shield), and P3 (aluminum-plastic composite tape shield).

With the introduction of the above symbols, is it clear to see the various cable products again.

The principle of omission in the model

Copper is the main conductor material used in cable products, so the copper core code T is omitted, except for bare wire and bare conductor products.

Bare wire and bare conductor products, power cables, and electromagnetic wire products do not indicate the major class code, electrical equipment and communication cables are not listed, but the small class or series code.

Item 7 is a variety of special occasions or additional special use requirements of the mark, in the “-” after the phonetic alphabet mark.

Sometimes to highlight the item, the item is written to the forefront.

Such as ZR- (flame retardant), NH- (fire-resistant), and WDZ- (low smoke halogen-free, enterprise standards).

How to choose the cable conductor material?

The choice of cable conductor material

The metal conductor with better conductivity is silver, followed by copper and aluminum.

Due to the high price of silver, in addition to the use of silver on special occasions and special purposes, a variety of cables commonly used conductors are copper core wire or aluminum core wire.

Copper is a good conductor of electricity, with conductive properties second only to silver.

And copper mechanical strength is high and easy to calendaring. Draw and welding, and other processing. With good physical and mechanical properties and excellent process performance.

Because of the situation that copper and aluminum resources tend to decrease, copper is about the early depletion of mineral resources on earth.

From the perspective of scientific development, aluminum instead of copper is the inevitable development trend.

In terms of cable conductors, due to the lower strength of aluminum, pulling a thin line is more difficult. The current processing of soft conductors and ultra-soft conductors is not realistic.

But the cross-sectional area of more than 4mm2 cable can be completely assured that the use of aluminum conductors, the force to promote the aluminum instead of copper.

Both to ensure the transmission function, but also to reduce input costs, in line with the strategy of sustainable development.

Copper-core cables should be used in the following situations

(1) Need to ensure reliable connection in the long-term operation of the circuit. Such as important power supply, and important operating circuits. And secondary circuits, the excitation of the motor, mobile equipment lines, and the lines of severe vibration occasions.

(2) Explosion hazard or fire hazard circuits.

(3) Serious corrosion of aluminum and minor corrosion of copper.

(4) Particularly important public buildings, command center places of the military, and important office buildings of the party and government. And subway stations.

(5) The place next to high-temperature equipment.

(6) With emergency systems and fire-fighting systems-related occasions.

(7) Fire-resistant cables.

(8) The working current is larger, they need to increase the number of cable occasions.

In addition, in high-rise buildings, large and medium-sized computer room buildings. And important public buildings. To adapt to foreign requirements of domestic and foreign-funded projects and other projects should give priority to copper core conductors.

The above is a comprehensive introduction to some of the cables. If you have any questions about the purchase of cables or cable basics, welcome to consult us, we will have the most professional cable sales representatives to solve your questions.