The basic knowledge of cable is a lot, very complicated. Today, I have put together some, I hope to help you.

Bare wire

Bare wire and bare conductor products refer to conductive wire without insulation and sheath, mainly including bare single wire, bare stranded wire and profile three series products.

Copper aluminum single wire: including soft copper single wire, hard copper single wire, soft aluminum single wire, hard aluminum single wire. Mainly used for a variety of wire and cable half products, a small amount of communication wire and electrical machinery manufacturing.

Bare stranded wire: including hard copper stranded wire (TJ), hard aluminum stranded wire (LJ), aluminum alloy stranded wire (LHAJ), steel core aluminum stranded wire (LGJ), mainly used in overhead laying. Soft copper stranded wire (TJR), soft aluminum stranded wire (LJR), mainly used for the connection of electrical equipment and electronic appliances or components. The specifications of each strand range from 1.0 to 300mm2.

Steel core aluminum stranded wire (LGJ)/nominal size with nominal aluminum section of steel section, said it is the most commonly used distribution circuit on a wire, the higher the, the greater the strength of the wire and steel core section, except the ordinary steel core aluminum stranded wire and steel core aluminum stranded wire, aluminum steel core aluminum stranded wire, anticorrosive steel core aluminum stranded wire, the steel core aluminum stranded wire reinforcement, such as lead, gap type lead times the capacity.

There are two commonly used: steel core aluminum strand JL/G1A(original model LGJ) to implement the standard GB/T1179-2008, aluminum strand JL(original model LJ) to implement the standard GB/T1179-2008. Specifications as follows: 10/2, 16/3, 25/4, 35/6, 50/8, 70/10, 70/40, 95/15, 95/20, 95/55, 120/7, 120/20, 120/25, 120/70, 150/8, 150/20, 150/25, 150/35, 185/10, 185/185 25, 185/30, 185/45, 240/30, 240/40, 240/55 ~ 800/100, etc.

Example:

JL/G1A-240/30-24/7(LGJ-240/30) is made of 24 duralumin wire and 7 A grade plating common strength galvanized steel wire steel core aluminum strand, duralumin wire nominal section of 240mm2, steel nominal section of 30 mm2.

Power cable

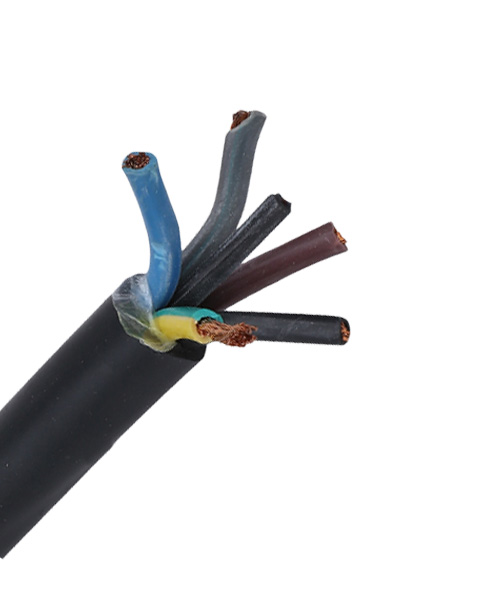

Power cable products used for transmission and distribution of high-power electric energy in the main lines of the power system, including 1 ~ 330kV and above all voltage levels, all kinds of insulated power cables. The cross section is 1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240, 300, 400, 500, 630, 800mm2, and the number of cores is 1, 2, 3, 4, 5, 3+1 cores.

The main features of such products are: extruding (wrapping) an insulating layer outside the conductor, stranding a few cores (corresponding to the phase line, zero line and ground line of the power system), and then adding a sheath layer, such as plastic/rubber sleeve wire and cable. The main process technologies include drawing, stranding, insulation extrusion (wrapping), cable forming, armor, sheath extrusion, etc. There are some differences in different process combinations of various products.

Power cables are divided into low-voltage cables, medium-voltage cables and high-voltage cables according to voltage grades. According to the insulation situation, it is divided into plastic insulated cable, rubber insulated cable, mineral insulated cable and so on.

1. Low-voltage cable: namely, the voltage level is 0.6/1kV

aluminum core (/ copper core) cross-linked polyethylene (steel tape armored) PVC sheathed power cable

Aluminum core (/ copper core) cross-linked power cable YJV, YJLV, YJV22, YJLV22 (XLPE insulation)

Model Description: Aluminum core XLPE insulated steel tape armoured PVC sheathed

YJ cross-linked polyethylene insulation

L aluminum core

V PVC sheath

22 Steel tape armouring (single-core cable is denoted as 62, that is, magnetically armoured tape)

Expression method: YJV, YJLV, YJV22, YJLV22 (the number of cores is 1-5)

Example:

Copper core cross-linked polyethylene insulated steel tape armored PVC sheathed power cable, rated voltage 0.6/1kV, 3+1 core, main core nominal cross-sectional area 120mm2, neutral line nominal cross-sectional area 70mm2 cable is shown as:

KYJV – 450/750 v 4 * 1.5 GB/T9330-2008

For example, the one-core cable is YJV-1*35

Two-core cable representation: YJV-2*35 (equal section)

Three-core cable representation: YJV-3*35 (equal section)

Four-core cable: YJV-4*35 (equal section) or YJV-3*35+1*16

Five-core cable representation: YJV-5*35 (equal section)

YJV 35 + 1-4 * * 16 or YJV 35 + 3 * 2 * 16

For example, five-core cable :VV-5 x 16 VV-4 x 16+1 x 10 VV-3 x 16+2 x 10

2. Medium voltage cable: Voltage class: 6/6kV, 8.7/10kV (15kV), 12/20kV, 26/35kV (this voltage class cable is cross-linked power cable)

Expression Method: YJV, YJLV, YJSV, YJV22, YJLV22 (the number of cores is 1 or 3 cores)

Specifications: 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240, 300, 400 (the number of cores is 1 or 3 cores)

For example: YJV22-8.7/15kV 3*240; YJV – 8.7/15 kv 3 * 150

3. high voltage cable: voltage level: above 35kV

Overhead insulated wire

The main features of such products are: extruding (wrapping) an insulating layer outside the conductor, stranding a few cores (corresponding to the phase line, zero line and ground line of the power system), and then adding a sheath layer, such as plastic/rubber sleeve wire and cable. The main process technologies include drawing, stranding, insulation extrusion (wrapping), cable forming, armor, sheath extrusion, etc. There are some differences in different process combinations of various products.

This kind of products are mainly used in the distribution, transmission, transformer, power supply lines in the strong electric power transmission, through the current (tens of amps to thousands of amps), high voltage (220V to 500kV and above).

Power cables are divided into low-voltage cables, medium-voltage cables and high-voltage cables according to voltage grades. According to the insulation situation, it is divided into plastic insulated cable, rubber insulated cable, mineral insulated cable and so on.

Usually divided into two kinds according to voltage level

1. voltage level: 1kV aluminum core (/ copper core) overhead insulated wire

Gauge: 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240, 300, 400 (the number of cores is 1 ~ 4)

Expression: JKLY, JKLYJ, JKLGY, JKLGV, JKY, JKYJ

Model description: (” JK “overhead insulation,” L “aluminum core,” Y “polyethylene insulation,” YJ “cross-linked polyethylene insulation,” V “PVC insulation,” G “steel core reinforced)

For example, JKLY-1kV 2*25; 1 * 240/30 kv JKLGY – 1; JKYJ-1kV 1/185

2. voltage level: 10kV aluminum core (/ copper core) overhead insulated wire

Specifications: 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240, 300, 400 (the number of cores is 1)

Expression: JKLY, JKLYJ, JKLGY, JKY, JKYJ

Model description: (” JK “overhead insulation,” L “aluminum core,” Y “polyethylene insulation,” YJ “cross-linked polyethylene insulation,” V “PVC insulation,” G “steel core reinforced)

For example, JKLY-10kV 1*25; JKLGY 1 * 240-10 kv; JKYJ-10kV 1*185

Control cable

The main characteristics of this kind of products are: similar to power cable structure, compared with power cable only copper cable without aluminum core cable, conductor section is smaller, more cores.

The MAIN characteristics of the products are: a wide range of varieties and specifications, a wide range of applications, suitable for AC rated voltage 450/750V and below, power stations, substations, mines, petrochemical enterprises and other single control or unit equipment control.

In order to improve the ability of internal and external control signal cable interference, mainly set shield measures, commonly used shielding structure according to the usage situation and shielding effect is different, basically has the following structure: copper wire braided shielding (P) code, aluminum-plastic composite belt shielding (P3) code, copper tape screened the code (P2), the total screen split screen composite shielding, etc.

Methods: KVV, KYJV, KYJV22, KVV22, KVVP, KVVP2, KVVP2-22, KYJVP, KYJVP2, KYJVP2-22, etc.

Model description: (” K “control cable,” V “PVC insulation,” YJ “cross-linked polyethylene insulation,” V “PVC sheath,” P “copper wire shielding,” P2 “copper tape shielding)

Voltage level: 450/750V

Number of cores: 2 ~ 37 cores

Cross-sectional area: 0.75 to 10mm2

Example:

Copper core cross-linked polyethylene insulated PVC sheathed control cable, rated voltage 450/750V, 4 core, 1.5mm2 cable is shown as:

KYJV – 450/750 v 4 * 1.5 GB/T9330-2008

The copper core PVC insulated PVC copper belt sheathed steel belt armored control cable, rated voltage 450/750V, 37 core, 2.5mm cable is shown as:

37 KVVP2-22-450/750 v * 2.5 GB/T9330-2008

Wire cloth

Method of expression:

BV: copper core PVC insulated wire, voltage class: 300/500V, executive standard: JB8734.2-1998

BVR: copper core PVC insulated flexible wire, voltage class: 450/750V, executive standard: JB8734.2-1998

BVV: copper conductor PVC insulated PVC sheathed cable, voltage class: 450/750V, executive standard: JB8734.2-1998

BLVV: Aluminum conductor PVC insulated PVC sheathed cable, voltage class: 300/500V, executive standard: JB8734.2-1998

BVVB: copper conductor PVC insulated PVC sheathed flat cable, voltage class: 300/500V, executive standard: JB8734.2-1998

RV: copper core PVC insulated flexible wire, voltage class: 300V

RVP: copper core PVC insulated shielded flexible wire, voltage class: 300V, executive standard: JB8734.2-1998

RVB: flat wire without sheath, voltage class: 300V, standard: GB5023.5-1997

RVS: flexible cable for copper core PVC insulated stranded connection, voltage class: 300V, standard: GB5023.5-1997

RVV: common type PVC sheath flexible wire, pressure grade: 300/500V, executive standard: GB5023.5-1997

RVVP: copper conductor PVC insulated PVC sheathed flexible wire, voltage class: 300V, executive standard: JB8734.5-1998

Number of cores: 1 ~ 5 cores

Cross-section: 0.5 ~ 185mm2

For example, BV-185; BLV – 25; BVR – 50; BVV – 2 * 1.5; RVP – 1 * 1.5; BVVB-2*4

Special cable

Special cables are cables with special functions, including flame retardant cable (ZR), low smoke and low halogen cable (DL), low smoke and halogen free cable (WL), fire resistant cable (NH), explosion-proof cable (FB), rat proof cable and termite proof cable (FS), water resistance cable (ZS), etc. The type of special power cable shall be marked with special code before the ordinary type.

Flame retardant cable (ZR), low smoke and low halogen cable (DL), low smoke and no halogen cable (WL) are mainly suitable for important power and control systems. When the line in case of fire, the cable under the action of the external flame can only be limited combustion, smoke less, smoke harmful gases (halogen) is very few.

When the external flame disappears, the cable can also extinguish itself, so that the damage to human body and property is reduced to a minimum. Therefore, this kind of cable is widely used in petrochemical, electric power, metallurgy, high-rise buildings and densely populated and other important places.

Fire-resistant cables (NH) are mainly used in particularly important power and control systems. When the line in case of fire, refractory cable can resist 750~800℃ high temperature for more than 90 minutes, to ensure safe power transmission, in order to win enough time for fire prevention and mitigation, so this cable is widely used in petrochemical, electric power, metallurgy, high-rise buildings and densely populated and other important places.

In the face of special occasions, new products are constantly derived, such as fire-resistant cables, fire-retardant cables, low-smoke halogen-free/low-smoke halogen-free cables, anti-termite/anti-rat cables, oil/cold/temperature/wear resistance cables, irradiation cross-linked cables, etc.

In recent years, with the environment of industrial and civil facilities and the strict control of the impact of primary and secondary disasters after fire, fire-resistant, low-smoke, low-halogen, low-smoke and halogen free flame retardant control cables have been developed successively, and their structural parameters are basically the same as those of conventional control cables. The characteristic parameters are the same as the special plastic cable.